Abstract

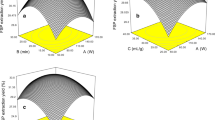

Camellia oleifera shells are a noteworthy by-product often considered as agricultural waste and discarded rather than efficiently used. The extraction of bioactive compounds from shells using green extraction process can be a better approach for waste valorization. Also, demand for novel and green extraction method is required to avoid organic solvents, high cost, and environmental problems. Nanobubbles (NBs) can be used for extraction purposes due to their high specific area and internal pressure. In this study, a novel method using nanobubbles (NBs) solution coupled with ultrasonication to extract phytochemicals from Camellia Oleifera shells (COSs) was first explored. The characterization was performed to measure the size, zeta potential, and surface tension of NBs stabilized by biosurfactant in this case rhamnolipid (Rh). The produced NBs were of size 100 nm, having a surface tension of 35.26 ± 0.31 mN/m−1. Single-factor experiments were performed to determine the significant variables. The Box–Behnken design optimized the ultrasonic power, ultrasonic time, and surfactant concentration to maximize the phytochemicals extraction. NBs solution coupled with ultrasonication (US) leads to a higher extraction yield of total phenolic (34.42 mg of gallic acid equivalent per gram of dry weight (mg GAE/g DW)) and flavonoid content (23.36 mg of rutin equivalent per gram of dry weight (RE/g DW)), as compared to the conventional extraction method. In addition, in vitro antioxidant activity was also increased in NBs solution and NBs’ solution–US extract compared with the conventional solvent method. The morphological and microstructural changes under NBs solution and ultrasonication were also determined to provide a possible extraction mechanism. The present experiment provides a novel extraction method and an overall green perspective of agro and food waste valorization.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analysed during the current study are available from the corresponding author on reasonable request.

References

Altemimi, A., Watson, D. G., Choudhary, R., Dasari, M. R., & Lightfoot, D. A. (2016). Ultrasound assisted extraction of phenolic compounds from peaches and pumpkins. PLoS One, 11(2), 1–20. https://doi.org/10.1371/journal.pone.0148758

Arruda, H. S., Silva, E. K., Pereira, G. A., Angolini, C. F. F., Eberlin, M. N., Meireles, M. A. A., & Pastore, G. M. (2019). Effects of high-intensity ultrasound process parameters on the phenolic compounds recovery from araticum peel. Ultrasonics Sonochemistry, 50(August), 82–95. https://doi.org/10.1016/j.ultsonch.2018.09.002

Belwal, T., Chemat, F., Venskutonis, P. R., Cravotto, G., Jaiswal, D. K., Bhatt, I. D., & Luo, Z. (2020). Recent advances in scaling-up of non-conventional extraction techniques: Learning from successes and failures. TrAC - Trends in Analytical Chemistry, 127, 115895. https://doi.org/10.1016/j.trac.2020.115895

Belwal, T., Huang, H., Li, L., Duan, Z., Zhang, X., Aalim, H., & Luo, Z. (2019). Optimization model for ultrasonic-assisted and scale-up extraction of anthocyanins from Pyrus communis ‘Starkrimson’ fruit peel. Food Chemistry, 297(March). https://doi.org/10.1016/j.foodchem.2019.124993

Chemat, F., Rombaut, N., Sicaire, A. G., Meullemiestre, A., Fabiano-Tixier, A. S., & Abert-Vian, M. (2017). Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A Review. Ultrasonics Sonochemistry, 34, 540–560. https://doi.org/10.1016/j.ultsonch.2016.06.035

Davis, E. J., Spadoni Andreani, E., & Karboune, S. (2021). Production of extracts composed of pectic oligo/polysaccharides and polyphenolic compounds from cranberry pomace by microwave-assisted extraction process. Food and Bioprocess Technology, 14(4), 634–649. https://doi.org/10.1007/s11947-021-02593-3

Deotale, S. M., Dutta, S., Moses, J. A., & Anandharamakrishnan, C. (2020). Stability of instant coffee foam by nanobubbles using spray-freeze drying technique. Food and Bioprocess Technology, 13(11), 1866–1877. https://doi.org/10.1007/s11947-020-02526-6

Ebina, K., Shi, K., Hirao, M., Hashimoto, J., Kawato, Y., Kaneshiro, S., & Yoshikawa, H. (2013). Oxygen and air nanobubble water solution promote the growth of plants, fishes, and mice. PLoS One, 8(6), 1–8. https://doi.org/10.1371/journal.pone.0065339

Eslami, P., Hajfarajollah, H., & Bazsefidpar, S. (2020). Recent advancements in the production of rhamnolipid biosurfactants by Pseudomonas aeruginosa. RSC Advances, 10(56), 34014–34032. https://doi.org/10.1039/d0ra04953k

Ettoumi, F., Zhang, R., Belwal, T., Javed, M., Xu, Y., Li, L., & Luo, Z. (2021). Generation and characterization of nanobubbles in ionic liquid for a green extraction of polyphenols from Carya cathayensis Sarg. Food Chemistry, 369(June 2021), 130932. https://doi.org/10.1016/j.foodchem.2021.130932

Ferreira, S. L. C., Bruns, R. E., Ferreira, H. S., Matos, G. D., David, J. M., Brandão, G. C., & dos Santos, W. N. L. (2007). Box-Behnken design: an alternative for the optimization of analytical methods. Analytica Chimica Acta, 597(2), 179–186. https://doi.org/10.1016/j.aca.2007.07.011

Fu, X., Belwal, T., Cravotto, G., & Luo, Z. (2020). Sono-physical and sono-chemical effects of ultrasound: Primary applications in extraction and freezing operations and influence on food components. Ultrasonics Sonochemistry, 60(June 2019), 104726. https://doi.org/10.1016/j.ultsonch.2019.104726

Fu, X., Wang, D., Belwal, T., Xu, Y., Li, L., & Luo, Z. (2021). Sonication-synergistic natural deep eutectic solvent as a green and efficient approach for extraction of phenolic compounds from peels of Carya cathayensis Sarg. Food Chemistry, 355(November 2020), 129577. https://doi.org/10.1016/j.foodchem.2021.129577

Gallo, M., Ferrara, L., & Naviglio, D. (2018). Application of ultrasound in food science and technology: A perspective. Foods, 7, 1–19. https://doi.org/10.3390/foods7100164

Grillo, G., Boffa, L., Binello, A., Mantegna, S., Cravotto, G., Chemat, F., & Telysheva, G. (2019). Cocoa bean shell waste valorisation; extraction from lab to pilot-scale cavitational reactors. Food Research International, 115, 200–208. https://doi.org/10.1016/j.foodres.2018.08.057

Hayakumo, S., Arakawa, S., Takahashi, M., Kondo, K., Mano, Y., & Izumi, Y. (2014). Effects of ozone nano-bubble water on periodontopathic bacteria and oral cells - in vitro studies. Science and Technology of Advanced Materials, 15(5). https://doi.org/10.1088/1468-6996/15/5/055003

Hosseinzadeh, R., Khorsandi, K., & Hemmaty, S. (2013). Study of the effect of surfactants on extraction and determination of polyphenolic compounds and antioxidant capacity of fruits extracts. PLoS One, 8(3), 1–7. https://doi.org/10.1371/journal.pone.0057353

Huang, H., Belwal, T., Jiang, L., Hu, J., Limwachiranon, J., Li, L., & Luo, Z. (2019). Valorization of lotus byproduct (Receptaculum Nelumbinis) under green extraction condition. Food and Bioproducts Processing, 115, 110–117. https://doi.org/10.1016/j.fbp.2019.03.006

Iftikhar, M., Zhang, H., Iftikhar, A., Raza, A., Begum, N., Tahamina, A., & Wang, J. (2020). Study on optimization of ultrasonic assisted extraction of phenolic compounds from rye bran. Lwt, 134(September), 110243. https://doi.org/10.1016/j.lwt.2020.110243

Ismail, B. B., Guo, M., Pu, Y., Wang, W., Ye, X., & Liu, D. (2019). Valorisation of baobab (Adansonia digitata) seeds by ultrasound assisted extraction of polyphenolics. Optimisation and comparison with conventional methods. Ultrasonics Sonochemistry, 52(October 2018), 257–267. https://doi.org/10.1016/j.ultsonch.2018.11.023

Jadhav, A. J., & Barigou, M. (2020). Bulk nanobubbles or not nanobubbles: That is the question. Langmuir, 36(7), 1699–1708. https://doi.org/10.1021/acs.langmuir.9b03532

Jiang, L., Belwal, T., Huang, H., Ge, Z., Limwachiranon, J., Zhao, Y., & Luo, Z. (2019). Extraction and characterization of phenolic compounds from bamboo shoot shell under optimized ultrasonic-assisted conditions: a potential source of nutraceutical compounds. Food and Bioprocess Technology, 12(10), 1741–1755. https://doi.org/10.1007/s11947-019-02321-y

Khodadadi Darban, A., & Ahmadi, R. (2013). Modelado y optimización de la generación de nano burbujas. Proceso utilizando la metodología de superficie de respuesta. International Journal of Nanoscience and Nanotechnology, 9(3), 151–162. Retrieved from http://www.ijnnonline.net/article_4012_f2576be4566b28d4a33684cae33b12a6.pdf

Kumar, D., Singh, A., & Mishra, D. K. (2016). Role of surfactant head group and chain length in aqueous lubrication: Steel-steel contact. Proceedings of the Institution of Mechanical Engineers, Part j: Journal of Engineering Tribology, 230(8), 968–973. https://doi.org/10.1177/1350650115621017

Kumari, B., Tiwari, B. K., Hossain, M. B., Brunton, N. P., & Rai, D. K. (2018). Recent advances on application of ultrasound and pulsed electric field technologies in the extraction of bioactives from agro-industrial by-products. Food and Bioprocess Technology, 11(2), 223–241. https://doi.org/10.1007/s11947-017-1961-9

Kumari, B., Tiwari, B. K., Hossain, M. B., Rai, D. K., & Brunton, N. P. (2017). Ultrasound-assisted extraction of polyphenols from potato peels: Profiling and kinetic modelling. International Journal of Food Science and Technology, 52(6), 1432–1439. https://doi.org/10.1111/ijfs.13404

Lee, J. I., Yim, B. S., & Kim, J. M. (2020). Effect of dissolved-gas concentration on bulk nanobubbles generation using ultrasonication. Scientific Reports, 10(1), 1–7. https://doi.org/10.1038/s41598-020-75818-8

Li, F., Chen, G., & Fu, X. (2016). Comparison of effect of gear juicer and colloid mill on microstructure, polyphenols profile, and bioactivities of Mulberry (Morus indica L.). Food and Bioprocess Technology, 9(7), 1233–1245. https://doi.org/10.1007/s11947-016-1715-0

Mahdi, A. A., Rashed, M. M. A., Al-Ansi, W., Ahmed, M. I., Obadi, M., Jiang, Q., & Wang, H. (2019). Enhancing bio-recovery of bioactive compounds extracted from Citrus medica L. Var. sarcodactylis: optimization performance of integrated of pulsed-ultrasonic/microwave technique. Journal of Food Measurement and Characterization, 13(3), 1661–1673. https://doi.org/10.1007/s11694-019-00083-x

Meegoda, J. N., Aluthgun Hewage, S., & Batagoda, J. H. (2018). Stability of nanobubbles. Environmental Engineering Science, 35(11), 1216–1227. https://doi.org/10.1089/ees.2018.0203

Mehmood, A., Ishaq, M., Zhao, L., Yaqoob, S., Safdar, B., Nadeem, M., & Wang, C. (2019). Impact of ultrasound and conventional extraction techniques on bioactive compounds and biological activities of blue butterfly pea flower (Clitoria ternatea L.). Ultrasonics Sonochemistry, 51(October), 12–19. https://doi.org/10.1016/j.ultsonch.2018.10.013

Nirmalkar, N., Pacek, A. W., & Barigou, M. (2018). Interpreting the interfacial and colloidal stability of bulk nanobubbles. Soft Matter, 14(47), 9643–9656. https://doi.org/10.1039/c8sm01949e

Oh, S. H., & Kim, J. (2017). Generation and Stability of Bulk Nanobubbles. 10–15. https://doi.org/10.1021/acs.langmuir.7b00510

Oh, S. H., Yoon, S. H., Song, H., Han, J. G., & Kim, J. M. (2013). Effect of hydrogen nanobubble addition on combustion characteristics of gasoline engine. International Journal of Hydrogen Energy, 38(34), 14849–14853. https://doi.org/10.1016/j.ijhydene.2013.09.063

Pandey, A., Belwal, T., Sekar, K. C., Bhatt, I. D., & Rawal, R. S. (2018). Optimization of ultrasonic-assisted extraction (UAE) of phenolics and antioxidant compounds from rhizomes of Rheum moorcroftianum using response surface methodology (RSM). Industrial Crops and Products, 119(April), 218–225. https://doi.org/10.1016/j.indcrop.2018.04.019

Pinto, D., Vieira, E. F., Peixoto, A. F., Freire, C., Freitas, V., Costa, P., & Rodrigues, F. (2021). Optimizing the extraction of phenolic antioxidants from chestnut shells by subcritical water extraction using response surface methodology. Food Chemistry, 334(July 2020), 127521. https://doi.org/10.1016/j.foodchem.2020.127521

Pongsumpun, P., Iwamoto, S., & Siripatrawan, U. (2020). Response surface methodology for optimization of cinnamon essential oil nanoemulsion with improved stability and antifungal activity. Ultrasonics Sonochemistry, 60(April 2019), 104604. https://doi.org/10.1016/j.ultsonch.2019.05.021

Sharma, S., Kori, S., & Parmar, A. (2015). Surfactant mediated extraction of total phenolic contents (TPC) and antioxidants from fruits juices. Food Chemistry, 185, 284–288. https://doi.org/10.1016/j.foodchem.2015.03.106

Shiroodi, S., Schwarz, M. H., Nitin, N., & Ovissipour, R. (2021). Efficacy of nanobubbles alone or in combination with neutral electrolyzed water in removing escherichia coli O157:H7, vibrio parahaemolyticus, and listeria innocua biofilms. Food and Bioprocess Technology, 14(2), 287–297. https://doi.org/10.1007/s11947-020-02572-0

Skrypnik, L., & Novikova, A. (2020). Response surface modeling and optimization of polyphenols extraction from apple pomace based on nonionic emulsifiers. Agronomy, 10(1). https://doi.org/10.3390/agronomy10010092

Song, R., Ismail, M., Baroutian, S., & Farid, M. (2018). Effect of subcritical water on the extraction of bioactive compounds from carrot leaves. Food and Bioprocess Technology, 11(10), 1895–1903. https://doi.org/10.1007/s11947-018-2151-0

Su, D. L., Li, P. J., Quek, S. Y., Huang, Z. Q., Yuan, Y. J., Li, G. Y., & Shan, Y. (2019). Efficient extraction and characterization of pectin from orange peel by a combined surfactant and microwave assisted process. Food Chemistry, 286(January), 1–7. https://doi.org/10.1016/j.foodchem.2019.01.200

Sugano, K., Miyoshi, Y., & Inazato, S. (2017). Study of ultrafine bubble stabilization by organic material adhesion. Japanese Journal of Multiphase Flow, 31(3), 299–306. https://doi.org/10.3811/jjmf.31.299

Sukor, N. F., Jusoh, R., Kamarudin, N. S., Abdul Halim, N. A., Sulaiman, A. Z., & Abdullah, S. B. (2020). Synergistic effect of probe sonication and ionic liquid for extraction of phenolic acids from oak galls. Ultrasonics Sonochemistry, 62(November), 104876. https://doi.org/10.1016/j.ultsonch.2019.104876

Tutunchi, P., Roufegarinejad, L., Hamishehkar, H., & Alizadeh, A. (2019). Extraction of red beet extract with β-cyclodextrin-enhanced ultrasound assisted extraction: a strategy for enhancing the extraction efficacy of bioactive compounds and their stability in food models. Food Chemistry, 297(June), 124994. https://doi.org/10.1016/j.foodchem.2019.124994

Wang, Ye., Li, X., Zhou, Y., Huang, P., & Xu, Y. (2010). Preparation of nanobubbles for ultrasound imaging and intracelluar drug delivery. International Journal of Pharmaceutics, 384(1–2), 148–153. https://doi.org/10.1016/j.ijpharm.2009.09.027

Wang, Y., Ke, L., Yang, Q., Peng, Y., Hu, Y., Dai, L., & Fu, G. (2019). Biorefinery process for production of bioactive compounds and bio-oil from Camellia oleifera shell. International Journal of Agricultural and Biological Engineering, 12(5), 190–194. https://doi.org/10.25165/j.ijabe.20191205.4593

Xie, Y., Ge, S., Jiang, S., Liu, Z., Chen, L., Wang, L., & Peng, W. (2018). Study on biomolecules in extractives of Camellia oleifera fruit shell by GC–MS. Saudi Journal of Biological Sciences, 25(2), 234–236. https://doi.org/10.1016/j.sjbs.2017.08.006

Xu, J. Y., Yuan, T. Q., Xiao, L., & Sun, R. C. (2018). Effect of ultrasonic time on the structural and physico-chemical properties of hemicelluloses from Eucalyptus grandis. Carbohydrate Polymers, 195(December 2017), 114–119. https://doi.org/10.1016/j.carbpol.2018.04.067

Xu, Q., Nakajima, M., Liu, Z., & Shiina, T. (2011). Biosurfactants for microbubble preparation and application. International Journal of Molecular Sciences, 12(1), 462–475. https://doi.org/10.3390/ijms12010462

Yin, C., Fan, X., Fan, Z., Shi, D., & Gao, H. (2018). Optimization of enzymes-microwave-ultrasound assisted extraction of Lentinus edodes polysaccharides and determination of its antioxidant activity. International Journal of Biological Macromolecules, 111, 446–454. https://doi.org/10.1016/j.ijbiomac.2018.01.007

You, Y., Zhang, X., Li, P., Lei, F., & Jiang, J. (2020). Co-production of xylooligosaccharides and activated carbons from Camellia oleifera shell treated by the catalysis and activation of zinc chloride. Bioresource Technology, 306(February), 123131. https://doi.org/10.1016/j.biortech.2020.123131

Zhang, L., Wang, Y., Wu, D., Xu, M., & Chen, J. (2010). Comparisons of antioxidant activity and total phenolics of Camellia oleifera Abel fruit hull from different regions of China. Journal of Medicinal Plants Research, 4(14), 1407–1413. https://doi.org/10.5897/JMPR10.270

Zhang, S., & Li, X. (2018). Hypoglycemic activity in vitro of polysaccharides from Camellia oleifera Abel. seed cake. International Journal of Biological Macromolecules, 115(2017), 811–819. https://doi.org/10.1016/j.ijbiomac.2018.04.054

Zhang, Y. Y., Zhang, F., Zhang, Y. S., Thakur, K., Zhang, J. G., Liu, Y., & Wei, Z. J. (2019). Mechanism of juglone-induced cell cycle arrest and apoptosis in Ishikawa human endometrial cancer cells. Journal of Agricultural and Food Chemistry, 67(26), 7378–7389. https://doi.org/10.1021/acs.jafc.9b02759

Funding

The authors would like to acknowledge the support from the Key Research and Development Program of Zhejiang Province (2021C02014) and Agricultural and Social Development Research Initiative Design Program of Hangzhou (20212013B07), China.

Author information

Authors and Affiliations

Contributions

Miral Javed performed conceptualization, methodology, investigation, formal analysis, writing—original draft. Tarun Belwal did writing—review and editing. Zhang ruyuan contributed to methodology. Yanqun Xu done resources and visualization. Li Li did writing—review and editing. Zisheng Luo was involved in conceptualization, writing—review and editing, and supervision.

Corresponding author

Ethics declarations

Competing Interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Javed, M., Belwal, T., Ruyuan, Z. et al. Optimization and Mechanism of Phytochemicals Extraction from Camellia Oleifera Shells Using Novel Biosurfactant Nanobubbles Solution Coupled with Ultrasonication. Food Bioprocess Technol 15, 1101–1114 (2022). https://doi.org/10.1007/s11947-022-02793-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02793-5