Abstract

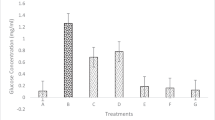

Olive residues waste is one of the most abundant wastes that is produced in many olive-cultivating countries especially Saudi Arabia. The current research is interested in the proper exploitation of this waste as a source of alternative energy such as bioethanol. The waste was submitted for physical/chemical and enzymatic hydrolysis to increase the amount of the produced glucose that would be microbially fermented into bioethanol. The obtained data revealed that the highest glucose units were produced through the hydrolysis of olive waste by 10% H2SO4 and autoclaving followed by enzymatic hydrolysis by cellulase enzyme (700 U/g). These sugars were fermented by Saccharomyces cerevisiae under anaerobic conditions into bioethanol with the concentration of 1.05 mg/ml. The produced ethanol was subsequently purified using poly (acrylonitrile-co-methylacrylate)/polymethylmethaacrylate [P(AN-co-MA)/PMMA] membrane modified with ethylenediamine (EDA), which represented the beginning of a new challenge in ethanol separation and purification from water. The characterization of the membrane was performed through the investigation of the functional groups and the morphology via Raman spectroscopy, Fourier transform infrared (FTIR), and scanning electron microscope (SEM). Recovery of ethanol from mixture (ethanol/water) of the prepared ethanol and another bioethanol produced as a product from the fermentation process was performed using the amicon cell filtration system with the prepared membrane which successfully increased the flux of ethanol for both the bioethanol and the prepared one.

Similar content being viewed by others

References

Abdelzaher H, Albahrawi A, Moustafa S (2015) Isolation of some biocontrol fungi from Saudi soil and their beneficial role as bio-fertilizers, Journal of Pure and Applied. Microbiology 9:541–549

Salomone R, Ioppolo G (2012) Environmental impacts of olive oil production: a Life Cycle Assessment case study in the province of Messina (Sicily). J Clean Prod 28:88–100

Aranda E, Sampedro I, Ocampo J, García-Romera I (2006) Phenolic removal of olive-mill dry residues by laccase activity of white-rot fungi and its impact on tomato plant growth. Int Biodeterior Biodegradation 58(3–4):176–179

El-Khateeb M, Tantry BA, Mohammed AH, Rahiman S (2014) Phenotypic characterization of phenol degrading microorganisms isolated from olive mill waste. Afr J Microbiol Res 8(21):2131–2136

Caputo MC, De Girolamo AM, Volpe A (2013) Soil amendment with olive mill wastes: impact on groundwater. J Environ Manag 131:216–221

Matsakas L, Christakopoulos P (2015) Ethanol production from enzymatically treated dried food waste using enzymes produced on-site. Sustainability 7(2):1446–1458

Fockink DH, Maceno MAC, Ramos LP (2015) Production of cellulosic ethanol from cotton processing residues after pretreatment with dilute sodium hydroxide and enzymatic hydrolysis. Biores Technol 187:91–96

Mahalakshmi M, Angayarkanni J, Rajendran R, Rajesh R (2011) Bioconversion of cotton waste from textile mills to bioethanol by microbial saccharification and fermentation. Ann Biol Res 2(3):380–388

Safartalab K, Dadashian F, Vahabzadeh F (2014) Fed batch enzymatic hydrolysis of cotton and viscose waste fibers to produce ethanol. Univers J Chem 2(1):11–15

Braide W, Kanu I, Oranusi U, Adeleye S (2016) Production of bioethanol from agricultural waste. J Fundam Appl Sci 8(2):372–386

Sarkar N, Ghosh SK, Bannerjee S, Aikat K (2012) Bioethanol production from agricultural wastes: an overview. Renew Energy 37(1):19–27

Domínguez-Bocanegra AR, Torres-Muñoz JA, López RA (2015) Production of bioethanol from agro-industrial wastes. Fuel 149:85–89

Li A, Antizar-Ladislao B, Khraisheh M (2007) Bioconversion of municipal solid waste to glucose for bio-ethanol production. Bioprocess Biosyst Eng 30(3):189–196

Taha RH, Taha TH, Abu-Saied M, Mansy A, Elsherif MA (2022) Maximization of the bioethanol concentration produced through the cardboard waste fermentation by using ethylenediamine-modifying poly (acrylonitrile-co-methyl acrylate) membrane. Biomass Convers Biorefin:1–19. https://doi.org/10.1007/s13399-022-02303-9

Bello RH, Linzmeyer P, Franco CMB, Souza O, Sellin N, Medeiros SHW, Marangoni C (2014) Pervaporation of ethanol produced from banana waste. Waste Manage 34(8):1501–1509

Zhu T, Xu S, Yu F, Yu X, Wang Y (2020) ZIF-8@ GO composites incorporated polydimethylsiloxane membrane with prominent separation performance for ethanol recovery. J Membr Sci 598:117681

Xiangli F, Wei W, Chen Y, Jin W, Xu N (2008) Optimization of preparation conditions for polydimethylsiloxane (PDMS)/ceramic composite pervaporation membranes using response surface methodology. J Membr Sci 311(1–2):23–33

Ong YK, Shi GM, Le NL, Tang YP, Zuo J, Nunes SP, Chung T-S (2016) Recent membrane development for pervaporation processes. Prog Polym Sci 57:1–31

Jiraratananon R, Chanachai A, Huang R, Uttapap D (2002) Pervaporation dehydration of ethanol–water mixtures with chitosan/hydroxyethylcellulose (CS/HEC) composite membranes: I. Effect of operating conditions. J Membr Sci 195(2):143–151

O’Brien DJ, Roth LH, McAloon AJ (2000) Ethanol production by continuous fermentation–pervaporation: a preliminary economic analysis. J Membr Sci 166(1):105–111

Jia Z, Wu G (2016) Metal-organic frameworks based mixed matrix membranes for pervaporation. Microporous Mesoporous Mater 235:151–159

Kopeć R, Meller M, Kujawski W, Kujawa J (2013) Polyamide-6 based pervaporation membranes for organic–organic separation. Sep Purif Technol 110:63–73

Smitha B, Suhanya D, Sridhar S, Ramakrishna M (2004) Separation of organic–organic mixtures by pervaporation—a review. J Membr Sci 241(1):1–21

Hou J, Sutrisna PD, Wang T, Gao S, Li Q, Zhou C, Sun S, Yang H-C, Wei F, Ruggiero MT (2019) Unraveling the interfacial structure–performance correlation of flexible metal–organic framework membranes on polymeric substrates. ACS Appl Mater Interfaces 11(5):5570–5577

Lipnizki F, Hausmanns S, Ten P-K, Field RW, Laufenberg G (1999) Organophilic pervaporation: prospects and performance. Chem Eng J 73(2):113–129

Sukitpaneenit P, Chung T-S, Jiang LY (2010) Modified pore-flow model for pervaporation mass transport in PVDF hollow fiber membranes for ethanol–water separation. J Membr Sci 362(1–2):393–406

Abu-Saied M, Taha TH, Elnaggar EM, Amer RA, Mansy A, Elkady GM (2018) Green production of bio-ethanol from cellulosic fiber waste and its separation using polyacrylonitrile-co-poly methyl acrylate membrane. Cellulose 25(11):6621–6644

Taha TH, Abu-Saied M, Elnaggar EM, Amer RA, Mansy AE, Elkady GM (2019) Using starchy waste as a promising raw material for bioethanol production with consequence purification using chitosan/sodium alginate polymeric membrane. J Biosci Appl Res 5(2):154–166

Dimos K, Paschos T, Louloudi A, Kalogiannis KG, Lappas AA, Papayannakos N, Kekos D, Mamma D (2019) Effect of various pretreatment methods on bioethanol production from cotton stalks. Fermentation 5(1):5

Amezcua-Allieri MA, Sánchez Durán T, Aburto J (2017) Study of chemical and enzymatic hydrolysis of cellulosic material to obtain fermentable sugars. J Chem 2017:9. https://doi.org/10.1155/2017/5680105

Caputi A, Ueda M, Brown T (1968) Spectrophotometric determination of ethanol in wine. Am J Enol Vitic 19(3):160–165

Abu-Saied M, El-Desouky E, Soliman E, Abd El-Naim G (2020) Novel sulphonated poly (vinyl chloride)/poly (2-acrylamido-2-methylpropane sulphonic acid) blends-based polyelectrolyte membranes for direct methanol fuel cells. Polym Test 89:106604

Abu-Saied M, Soliman E, Al Desouki E (2020) Development of proton exchange membranes based on chitosan blended with poly (2-acrylamido-2-methylpropane sulfonic acid) for fuel cells applications, Mater Today Commun 25:101536

Abu-Saied M, Elzatahry A, El-Khatib K, Hassan E, El-Sabbah M, Drioli E, MohyEldin M (2012) Preparation and characterization of novel grafted cellophane-phosphoric acid-doped membranes for proton exchange membrane fuel-cell applications. J Appl Polym Sci 123(6):3710–3724

Vasić K, Knez Ž, Leitgeb M (2021) Bioethanol production by enzymatic hydrolysis from different lignocellulosic sources. Molecules 26(3):753

Salam M, Pondith PC, Islam A, Khan MR, Uddin MR, Islam M (2013) Conversion of cellulosic waste into fermentable sugar: process optimization. J Chem Eng 28(1):27–31

Irfanullah NR, Arain MB, Shah N (2014) Conversion of cotton to glucose by base hydrolysis using various hydrolytic conditions. Pakhtunkhwa J Life Sci 2(03/04):125–137

Bhagia S, Dhir R, Kumar R, Wyman CE (2018) Deactivation of cellulase at the air-liquid interface is the main cause of incomplete cellulose conversion at low enzyme loadings. Sci Rep 8(1):1–12

El-Tayeb T, Abdelhafez A, Ali S, Ramadan E (2012) Effect of acid hydrolysis and fungal biotreatment on agro-industrial wastes for obtainment of free sugars for bioethanol production. Braz J Microbiol 43:1523–1535

Tomás-Pejó E, Oliva J, González A, Ballesteros I, Ballesteros M (2009) Bioethanol production from wheat straw by the thermotolerant yeast Kluyveromyces marxianus CECT 10875 in a simultaneous saccharification and fermentation fed-batch process. Fuel 88(11):2142–2147

Kim Y, Hendrickson R, Mosier NS, Ladisch MR, Bals B, Balan V, Dale BE (2008) Enzyme hydrolysis and ethanol fermentation of liquid hot water and AFEX pretreated distillers’ grains at high-solids loadings. Biores Technol 99(12):5206–5215

Jeihanipour A, Karimi K, Niklasson C, Taherzadeh MJ (2010) A novel process for ethanol or biogas production from cellulose in blended-fibers waste textiles. Waste Manage 30(12):2504–2509

Rajendran R, Radhai R, Sundaram KS, Rajalakshmi V (2015) Utilization of cellulosic biomass as a substrate for the production of bioethanol. Int J Environ Sci 5(4):743–753

Chen J-C, Guo J-S (2013) Improving the conversion efficiency of waste cotton to bioethanol by microwave hydrolysis technology. Sustain Environ Res 23(5):138260715

Saifuddin N, Refal H (2015) Optimization of fermentation parameters for bioethanol production from waste glycerol by microwave induced mutant Escherichia coli. Res J Pharm Biol Chem Sci 6(5):1449–1461

Talebnia F, Taherzadeh MJ (2012) Utilization of carbohydrates content of paper tube residuals for ethanol production. Carbohyd Polym 87(3):2149–2153

Cheng K-K, Wu J, Lin Z-N, Zhang J-A (2014) Aerobic and sequential anaerobic fermentation to produce xylitol and ethanol using non-detoxified acid pretreated corncob. Biotechnol Biofuels 7(1):1–9

Svetlitchnyi VA, Kensch O, Falkenhan DA, Korseska SG, Lippert N, Prinz M, Sassi J, Schickor A, Curvers S (2013) Single-step ethanol production from lignocellulose using novel extremely thermophilic bacteria. Biotechnol Biofuels 6(1):1–15

Boonchuay P, Techapun C, Leksawasdi N, Seesuriyachan P, Hanmoungjai P, Watanabe M, Srisupa S, Chaiyaso T (2021) Bioethanol production from cellulose-rich corncob residue by the thermotolerant Saccharomyces cerevisiae TC-5. J Fungi 7(7):547

Tan L, Han N, Zhang L, Qian Y, Zhang X, Cui Z, Cai J (2018) Preparation of bi-continuous poly (acrylonitrile-co-methyl acrylate) microporous membranes by a thermally induced phase separation method. J Appl Polym Sci 135(17):46173

Zhang P-Y, Xu Z-L, Yang H, Wei Y-M, Wu W-Z, Chen D-G (2013) Preparation and characterization of PVDF-P (PEGMA-r-MMA) ultrafiltration blend membranes via simplified blend method. Desalination 319:47–59

Yang HC, Wu MB, Li YJ, Chen YF, Wan LS, Xu ZK (2016) Effects of polyethyleneimine molecular weight and proportion on the membrane hydrophilization by codepositing with dopamine. J Appl Polym Sci 133(32). https://doi.org/10.1002/app.43792

Sahoo PK, Biswal T, Samal R (2011) Microwave-assisted preparation of biodegradable water absorbent polyacrylonitrile/montmorillonite clay nanocomposite. J Nanotechnol 2011:143973. https://doi.org/10.1155/2011/143973

Sahoo DR, Priyadarshini M, Biswal T (2021) Complex catalysed green synthesis and characterization of P (AN-co-MMA)/prawn shell powder biocomposite. Mater Today Proc 47:1224–1228

Biswal T, Samal R, Sahoo PK (2012) Microwave-assisted preparation of poly (2-EHA-co-ST) copolymer and poly (2-EHA-co-ST)/MMT nanocomposite. J Appl Polym Sci 125(2):1467–1475

Shukla S (2021) Synthesis, kinetics and characterization of environment friendly waterborne acrylate copolymers. Mater Today Proc 34:710–718

Liu G, Jin W (2021) Pervaporation membrane materials: recent trends and perspectives. J Membr Sci:119557

Amarante RC, Donaldson AA (2021) Pervaporation separation of ethanol and 2-ethylhexanol mixtures using cellulose acetate propionate and poly (1-vinylpyrrolidone-co-vinyl acetate) blend membranes. Sep Purif Technol 258:117953

Kamtsikakis A, McBride S, Zoppe JO, Weder C (2021) Cellulose nanofiber nanocomposite pervaporation membranes for ethanol recovery. ACS Appl Nano Mater 4(1):568–579

Bermudez Jaimes JH, Torres Alvarez ME, Bannwart de Moraes E, Wolf Maciel MR, Maciel Filho R (2020) Separation and semi-empiric modeling of ethanol–water solutions by pervaporation using PDMS membrane. Polymers 13(1):93

Samanta HS, Ray SK (2015) Separation of ethanol from water by pervaporation using mixed matrix copolymer membranes. Sep Purif Technol 146:176–186

Han X, Zhang X, Ma X, Li J (2016) Modified ZSM-5/polydimethylsiloxane mixed matrix membranes for ethanol/water separation via pervaporation. Polym Compos 37(4):1282–1291

Shi S, Du Z, Ye H, Zhang C, Li H (2006) A novel carbon black/polydimethylsiloxane composite membrane with high flux for the separation of ethanol from water by pervaporation. Polym J 38(9):949–955

Jia M-D, Pleinemann K-V, Behling R-D (1992) Preparation and characterization of thin-film zeolite–PDMS composite membranes. J Membr Sci 73(2–3):119–128

Zhu Z, Hu D, Liu Y, Xu Y, Zeng G, Wang W, Zhang Y, Cui F (2017) Three‐component mixed matrix organic/inorganic hybrid membranes for pervaporation separation of ethanol–water mixture. J Appl Polym Sci 134(17). https://doi.org/10.1002/app.44753

Zhan X, Li J-D, Fan C, Han X-L (2010) Pervaporation separation of ethanol/water mixtures with chlorosilane modified silicalite-1/PDMS hybrid membranes. Chin J Polym Sci 28(4):625–635

Acknowledgements

The authors extend their appreciation to the Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia for funding this work through the project number “375213500.” Also, the authors would like to extend their sincere appreciation to City of Scientific Research and Technological Applications and the Central Laboratory at Jouf University for supporting this study.

Funding

Deputyship for Research & Innovation, Ministry of Education in Saudi Arabia funded this work through the project number “375213500.”

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection, and analysis were performed by all of them, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Taha, R.H., Taha, T.H., Abu-Saied, M.A. et al. Successful production of bioethanol from olive waste residues followed by its purification using poly (acrylonitrile-co-methylacrylate)/polymethylmethaacrylate membrane. Biomass Conv. Bioref. 13, 16115–16129 (2023). https://doi.org/10.1007/s13399-022-02891-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02891-6