Abstract

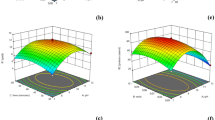

This research focused on the preparation of radish leaf protein concentrates (RLPC) by applying enzyme-assisted extraction, where α-amylase, protease, and xylanase were employed for the same. The α-amylase-assisted extraction showed maximum extraction yield (10.22%) and protein content (66.93%). Therefore, this method was optimized using response surface methodology where optimized conditions of extraction temperature (42.8 °C), amylase concentration (18,446 U), and extraction time (4.44 h) resulted in an extraction yield of 9.56% and protein content of 89.41% in the extracted RLPC. Fractionation of the protein concentrate demonstrated the maximum presence of glutelins followed by prolamins, albumins, and globulins. The apparent molecular weights of the RLPC and its isolated fractions ranged between 35 and 92 kDa. The RLPC showed a high in vitro protein digestibility (92.17%), considerable antioxidant activity (DPPH, FRAP, ABTS), and desirable structural and functional properties (water and oil holding capacity, emulsion capacity and stability, least gelation concentration, etc.). Threonine, methionine, and tryptophan were found to be the most abundant amino acids present in the RLPC. The microbial load of the stored RLPC was observed to be in acceptable range during 6 weeks of storage under ambient and refrigerated temperature conditions. Conclusively, α-amylase-extracted RLPC serves as a potential alternative edible plant-based protein fortification source for various food formulations.

Graphical Abstract

Similar content being viewed by others

Data availability

Available on request.

References

Ankita PK, Prasad K (2018) Characterization of dehydrated functional fractional radish leaf powder. Der Pharm Lett 7:269–279

CGIAR Genebank, Capacity building workshop on genetic resource policies for CGIAR scientists and partners in East Africa, 4–7 June 2019, ILRI Campus, Addis Ababa, Ethiopia (2019), https://cgspace.cgiar.org/handle/10568/106609

Du M, Xie J, Gong B, Xu X, Tang W, Li X, Xie M (2018) Extraction, physicochemical characteristics and functional properties of Mung bean protein. Food Hydrocoll 76:131–140. https://doi.org/10.1016/j.foodhyd.2017.01.003

Popoola JO, Wgwari LO, Bilewi Y, Omonigbehin E, Ogulana OO, Daramola F (2019) Proximate analysis and SDS-PAGE protein profiling of cassava leaves: utilization as leafy vegetable in Nigeria. MOJ Ecol Environ Sci 4:1–5. https://doi.org/10.15406/mojes.2019.04.00125

L. Telek, Leaf protein extraction from tropical plants, plants: the potentials for extracting protein 305 (1983).

Akyuz A, Ersus S (2021) Optimization of enzyme assisted extraction of protein from the sugar beet (Beta vulgaris L.) leaves for alternative plant protein concentrate production. Food Chem 335:127673. https://doi.org/10.1016/j.foodchem.2020.127673

Celik M, Melih G, Metin Y (2019) Effect of pH on protein extraction from sour cherry kernels and functional properties of resulting protein concentrate. J Food Sci Technol 6:3023–3032. https://doi.org/10.1007/s13197-019-03785-8

Kaur G, Bhatia S (2021) Characterization of radish leaf protein concentrates for biochemical, functional properties, antioxidant activity, mineral content and microbial stability. Int J Agric Sci 17:185–193. https://doi.org/10.15740/HAS/IJAS/17.2/185-193

Ahmadifard N, Mureta JHC, Abedian-Kenari A, Motamedzadegan A, Jamali H (2016) Comparison the effect of three commercial enzymes for enzymatic hydrolysis of two substrates (rice bran protein concentrate and soy-been protein) with SDS-PAGE. J Food Sci Technol 53:1279–1284. https://doi.org/10.1007/s13197-015-2087-6

Nadar SS, Rao P, Rathod VK (2018) Enzyme assisted extraction of biomolecules as an approach to novel extraction technology: A review. Food Res Int 108:309–330. https://doi.org/10.1016/j.foodres.2018.03.006

Choi H, Marufa N, Badrul A, Ahsan J, Alshammari FH, Kim S, Lee S (2022) Optimization of the extraction conditions of Nypa fruticans Wurmb using response surface methodology and artificial neural network. Food Chem 381:132086. https://doi.org/10.1016/j.foodchem.2022.132086

Daba SD, Morris CF (2022) Pea proteins: Variation, composition, genetics, and functional properties. Cer Chem 99:8–20. https://doi.org/10.1002/cche.10439

Box GE, Behnken DW (1960) Some new three level designs for the study of quantitative variables. Technometrics 2:455–475

AOAC, Official Methods of Analysis, 17th edn., Association of Official Analytical Chemists, Washington, D.C. (2000).

Kaur G, Bhatia S (2022) Radish leaf protein concentrates: optimization of alkaline extraction for production and characterization of an alternative plant protein concentrate. J Food Meas Charact. https://doi.org/10.1007/s11694-022-01411-4

Lowry OH (1951) Protein measurement with the Folin phenol reagent. J Biol, Chem 193:265–275

Laemmli UK (1970) Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature 227:680–685. https://doi.org/10.1038/227680a0

Lin CW, Yu CW, Wu SC, Yih KH (2009) DPPH Free-radical scavenging activity, total phenolic contents and chemical composition analysis of forty-two kinds of essential oils. J Food Drug Anal 17:386–395

Re R, Pellengrini N, Proteggente A, Pannala A, Yang M, Rice-Evans C (1999) Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med 26:1231–1237. https://doi.org/10.1016/S0891-5849(98)00315-3

Benzie FF, Strain JJ (1999) Ferric reducing/antioxidant power assay: direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. Meth Enzymol 299:15–27. https://doi.org/10.1016/S0076-6879(99)99005-5

Devi J, Bhatia S, Alam MS, Dhillon TS (2018) Effect of calcium and salicylic acid on quality retention in relation to antioxidative enzymes in radish stored under refrigerated conditions. J Food Sci Technol 55:1116–1126. https://doi.org/10.1007/s13197-017-3027-4

Mineskus M, Marie A, Paula A, Simon B, Yorsten B, Claire B, Frederic C (2014) A standardised static in vitro digestion method suitable for food–an international consensus. Food Func 5:1113–1237. https://doi.org/10.1039/C3FO60702J

Schelkopf CS, Rice EA, Swenson JK, Hess AM, Geomaras I, Belk KE, Nair MN (2021) Nix Pro Color Sensor provides comparable color measurements to HunterLab colorimeter for fresh beef. J Food Sci Technol 58:3661–3665. https://doi.org/10.1007/s13197-021-05077-6

Sharma N, Singh VK, Lee Y, Kumar S, Rai PK, Pathak AK, Singh VK (2020) Analysis of mineral elements in medicinal plant samples using LIBS and ICP-OES. At. Spectrosc 41:234–241. https://doi.org/10.46770/AS.2020.06.003

Yu J, Ahmedna M, Goktepe I (2007) Peanut protein concentrate: Production and functional properties as affected by processing. Food Chem 103:121–129. https://doi.org/10.1016/j.foodchem.2006.08.012

Lin MJY, Humbert ES, Sosulski FW (1974) Certain functional properties of sunflower meal products. J Food Sci 39:2. https://doi.org/10.1111/j.1365-2621.1974.tb02896.x

Yasumatsu K, Sawada K, Moritaka S, Misaki M, Toda J, Wada T, Ishii K (1972) Whipping and emulsifying properties of soybean products. Agric Biol Chem 36:719–727. https://doi.org/10.1080/00021369.1972.10860321

Sathe SK, Deshpande SS, Salunkhe DK (1982) Functional properties of winged bean [Psophocarpus tetragonolobus (L) DC] protein. J. Food Sci. 47:503–509. https://doi.org/10.1111/j.1365-2621.1982.tb10112.x

Huda N, Abdullah A, Babji AS (2001) Functional properties of surimi powder from three Malaysian marine fish 36:401–406. https://doi.org/10.1046/j.1365-2621.2001.00473.x

Joglekar AM, May AT (1987) Product excellence through design of experiments. Cer Foods World 32:857–868

Lapornik B, Prosek M, Wondra AG (2005) Comparison of extracts prepared from plant by-products using different solvents and extraction time. J Food Eng 71:214–222. https://doi.org/10.1016/j.jfoodeng.2004.10.036

Adebiyi P, Adebiyi AO, Hasegawa Y, Ogawa T, Muramoto K (2009) Isolation and characterization of protein fractions from deoiled rice bran. Eur Food Res Technol 228:391–401. https://doi.org/10.1007/s00217-008-0945-4

Lamsal P, Koegel RG, Gunasekaran S (2007) Some physicochemical and functional properties of alfalfa soluble leaf proteins, LWT-. Food Sci Technol 40:1520–1526. https://doi.org/10.1016/j.lwt.2006.11.010

Xie Z, Huang J, Hu X, Jin Z (2008) Antioxidant activity of peptides isolated from alfalfa leaf protein hydrolysate. Food Chem 111:370–376. https://doi.org/10.1016/j.foodchem.2008.03.078

Y. Y. Wang, C. Y. Wang, S. T. Wang, Y. Q. Li, H. Z. Mo, J. X. He, Physicochemical properties and antioxidant activities of tree peony (Paeonia suffruticosa Andr.) seed protein hydrolysates obtained with different proteases, Food Chem. 345 (2021) https://doi.org/10.1016/j.foodchem.2020.128765.

JA do Evangelho, NL Vanier, VZ Pinto, JJ De Berrios, ARG Dias, E da Rosa Zavareze, Black bean (Phaseolus vulgaris L) protein hydrolysates: Physicochemical and functional properties. Food Chem 214 (2017) 460–467

Chiu C, Santoyo M, Lara E, Sanchez JA (2021) Jackfruit (Artocarpus heterophyllus Lam) leaf as a new source to obtain protein hydrolysates: physicochemical characterization, techno-functional properties and antioxidant capacity. Food Hydrocoll 112:106319. https://doi.org/10.1016/j.fochx.2021.100138

A. Sodamade, M. Raimi, A. D. Owonikoko, A. T. Adebimpe, nutritive evaluation, mineral composition and phytochemical analysis of leaf protein concentrates of Daucus carota, Braz. J. Sci. Technol. 36 (2019) 57–68, https://www.ijtsrd.com/papers/ijtsrd26427.pdf.

Benhammouche T, Melo A, Martins Z, Faria MA, Pinho SC, Ferreira IM, Zaidi F (2021) Nutritional quality of protein concentrates from Moringa Oleifera leaves and in vitro digestibility. Food Chem 348:128858. https://doi.org/10.1016/j.foodchem.2020.128858

Ali MA, El Tinay AH, Ahmed IA, Babiker EE (2009) Supplementation of pearl millet with soybean: changes in protein digestibility, amino acid composition and sensory quality during processing. Elec J Environ Agric Food Chem 8:1068–1076

Fasuan TO, Omobuwaio TO, Gbadamosi SO (2018) Optimization of simultaneous recovery of oil and protein from sesame (Sesamum indicum) seed. J Food Process Preserv 42:1–10. https://doi.org/10.1111/jfpp.13341

Adiamo OQ, Gbadamosi OS, Abiose SH (2016) Functional properties and protein digestibility of protein concentrates and isolates produced from Kariya (H ildergadia bateri) seed. J Food Process Preserv 40:979–989. https://doi.org/10.1111/jfpp.12678

Adewumi OO, Felix-Minnar JV, Jideani VA (2022) Functional properties and amino acid profile of Bambara groundnut and Moringa oleifera leaf protein complex. Processes 10:205. https://doi.org/10.3390/pr10020205

Toews R, Wang N (2013) Physicochemical and functional properties of protein concentrates from pulses. Food Res Int 52:193–198. https://doi.org/10.1016/j.foodres.2012.12.009

Pumilia G, Chicon MJ, Cooperstone JL, Guffrida D, Dugo G, Schwartz SJ (2014) Changes in chlorophylls, chlorophyll degradation products and lutein in pistachio kernels (Pistacia vera L) during roasting. Food Res Int 65:193–198. https://doi.org/10.1016/j.foodres.2014.05.047

Ozdal T, Capanoglu E, Altay F (2013) A review on protein–phenolic interactions and associated changes. Food Res Int 51:954–970. https://doi.org/10.1016/j.foodres.2013.02.009

A. Sodamade, O. S. Bolaji, O. Adeboye, proximate analysis, mineral contents and functional properties of Moringa oleifera leaf protein concentrate. J Appl Chem (2013) 47-51, 10.6084/M9.FIGSHARE.1097420.

National Research Council, Recommended dietary allowances (1989).

Kudre TG, Benjakul S, Kishimura H (2013) Comparative study on chemical compositions and properties of protein isolates from mung bean, blac k bean and bambara groundnut. J Food Sci Agric 93:2429–2436. https://doi.org/10.1002/jsfa.6052

Krimm S, Bandekar J (1986) Vibrational spectroscopy and conformation of peptides, polypeptides, and proteins. Adv Protein Chem 38:181–364. https://doi.org/10.1016/S0065-3233(08)60528-8

Akyuz S, Akyuz T, Celik O, Atak C (2018) FTIR spectroscopy of protein isolates of salt-tolerant soybean mutants. J Appl Spectrosc 84:1019–1023. https://doi.org/10.1007/s10812-018-0580-1

Chen X, Ru Y, Chen F, Wang X, Zhao X, Ao Q (2013) FTIR spectroscopic characterization of soy proteins obtained through AOT reverse micelles. Food Hydrocoll 31:435–437. https://doi.org/10.1016/j.foodhyd.2012.11.017

Liu CM, Peng Q, Zhong JZ, Liu W, Jhong YJ, Wang F (2018) Molecular and functional properties of protein fractions and isolate from cashew nut (Anacardium occidentale L.). Molecules 23:393. https://doi.org/10.3390/molecules23020393

Piotrowicz BB, Salas-Mellado MM (2017) Protein concentrates from defatted rice bran: preparation and characterization. Food Sci Technol 37:165–172. https://doi.org/10.1590/1678-457X.34816

Sun C, Tang X, Ren Y, Wang E, Shi L, Wu X, Wu H (2019) Novel antioxidant peptides purified from mulberry (Morus Atropurpurea Roxb.) leaf protein hydrolysates with hemolysis inhibition ability and cellular antioxidant activity. J Agric Food Chem 67:7650–7659. https://doi.org/10.1021/acs.jafc.9b01115

Sun X, Zhang W, Zhang L, Tian S, Chen F (2020) Molecular and emulsifying properties of arachin and conarachin of peanut protein isolate from ultrasound-assisted extraction 132:109790. https://doi.org/10.1016/j.lwt.2020.109790

Fernandez-Quintela MT, Del Macarulla AS, Barrio JA (1997) Martinez, Composition and functional properties of protein isolates obtained from commercial legumes grown in northern Spain. Plant Food Hum Nutr 51:331–341. https://doi.org/10.1023/a:1007936930354

Fasuyi O, Aletor VA (2005) Varietal composition and functional properties of cassava (Manihot esculenta, Crantz) leaf meal and leaf protein concentrates. Pak J Nutr 4:43–39. https://doi.org/10.3923/pjn.2005.43.49

Subagio A (2006) Characterization of hyacinth bean (Lablab purpureus (L.) sweet) seeds from Indonesia and their protein isolate. Food Chem. 95:65–70. https://doi.org/10.1016/j.foodchem.2004.12.042

Ghribi M, Gafsi IM, Blecker C, Danthine S, Attia H, Besbes S (2015) Effect of drying methods on physico-chemical and functional properties of chickpea protein concentrates. J Food Eng 78:179–188. https://doi.org/10.1016/j.jfoodeng.2015.06.021

Aletor O, Oshodi AA, Ipinmoroti K (2002) Chemical composition of common leafy vegetables and functional properties of their leaf protein concentrates. Food Chem 78:63–68. https://doi.org/10.1016/S0308-8146(01)00376-4

Damodaran S (1997) Protein-stabilized foams and emulsions. Food Sci Technol 70:54–66

Shevkani K, Singh N, Kaur A, Rana JC (2015) Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocoll. 43:679–687. https://doi.org/10.1016/j.foodhyd.2014.07.024

Ogunwolu SO, Henshaw FO, Mock HP, Santros A, Awonorin SO (2009) Functional properties of protein concentrates and isolates produced from cashew (Anacardium occidentale L.) nut. Food Chem 115:852–858

Cheng J, Zhou S, Wu D, Chen J, Liu D, Ye X (2009) Bayberry (Myrica rubra Sieb. et Zucc) kernel: A new protein source. Food Chem 112:469–473

Garcia-Monero F, Solorzano E, Banhart J (2011) Kinetics of coalescence in liquid aluminium foams. Soft Matter 7:9216–9223. https://doi.org/10.1039/C1SM05831B

Cano-Medina A, Jimenez-Islas H, Dendooven L, Herrera RP, Gonzalez-Alatorre G, Escamilla-Silva EM (2011) emulsifying and foaming capacity and emulsion and foam stability of sesame protein concentrates. Food Res Int 44:684–692. https://doi.org/10.1016/j.foodres.2010.12.015

Wu H, Wang Q, Ma T, Ren J (2009) Comparative studies on the functional properties of various protein concentrate preparations of peanut protein. Food Res Int 42:343–348. https://doi.org/10.1016/j.foodres.2008.12.006

Fasuyi O (2006) Nutritional potentials of some tropical vegetable leaf meals: chemical characterization and functional properties. Afr J Biotechnol 5:49–53. https://doi.org/10.12691/jnh-3-1-3

FSSAI Specifications (2018) for dehydrated vegetable products. https://archive.fssai.gov.in

Acknowledgements

The authors acknowledge the Head, Department of Processing and Food Engineering and All India Coordinated Research Project on Post-harvest Engineering and Technology under ICAR, New Delhi, India, for providing facilities to carry out this research work.

Author information

Authors and Affiliations

Contributions

Methodology, laboratory research, investigation, data curation, writing (original draft preparation), Gurkanwal Kaur; conceptualization, supervision, writing (review and editing), Dr Surekha Bhatia.

Corresponding author

Ethics declarations

Ethical approval

This material is the authors’ own original work, which has not been previously published elsewhere.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• α-Amylase, protease, and xylanase were used to extract leaf protein concentrates from Raphanus sativus L. leaves.

• α-Amylase-assisted extraction showed maximum extraction yield (10.22%) and protein content (66.93%).

• Optimization of α-amylase-assisted extraction done using response surface methodology.

• At optimized extraction temperature (42.8 °C), amylase concentration (18446 U), and extraction time (4.44 h), a considerable extraction yield of 9.56% and protein content of 89.41% were obtained.

• High antioxidant activity, desirable functional properties, and acceptable microbial stability in protein concentrates.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaur, G., Bhatia, S. Alpha-amylase-assisted extraction of protein concentrates from Raphanus sativus L. leaves. Biomass Conv. Bioref. 13, 15051–15065 (2023). https://doi.org/10.1007/s13399-022-03611-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-03611-w