Abstract

For thousands of years, plant has been widely applied in the medical area and is an important part of human diet. A high content of nutrients could be found in all kinds of plants, and the most outstanding group of nutrients that attracts scientists’ attention is the high level of phenolic compounds. Due to the relationship between high phenolic compound content and high antioxidant capacity, plant extracts are expected to become a potential treatment for oxidation stress diseases including diabetes and cancer. However, according to the instability of phenolic compounds to light and oxygen, there are certain difficulties in the extraction of such compounds. But after many years of development, the extraction technology of phenolic compounds has been quite stable, and the only problem is how to obtain high-quality extracts with high efficiency. To further enhance the value of plant extracts, concentration and separation methods are often applied, and when detailed analysis is required, characterization methods including HPLC and LC/GC–MS will be applied to evaluate the number and type of phenolic compounds. A series of antioxidant assays are widely performed in numerous studies to test the antioxidant capacity of the plant extracts, which is also an important basis for evaluating value of extracts. This paper intends to provide a view of a variety of methods used in plants’ phenolic compound extraction, separation, and characterization. Furthermore, this review presents the advantages and disadvantages of techniques involved in phenolic compound research and provides selected representative bibliographic examples.

Similar content being viewed by others

Background

In 2600 BC, people in Mesopotamia developed around 100 plant-derived substances for medical purposes. Around 5000 years ago, natural drug molecules were recorded in the Indian Ayurveda system’s record. And in Chinese literature, countless use cases of herbs are recorded since 2500 years ago (Alves and Rosa 2007; Ekor 2014). But not just in the medical area, plants are also an important part of human’s daily diet. The human regular dietary sources can be divided into two parts, animal foods and plant foods. As Chen et al. (2018) mentioned in their work, plant foods have unique nutrients that do not exist in animal foods, so they can complement people’s daily dietary intake. In addition to the common nutrients such as minerals and protein that also exist in animal foods, the high nutrient value of plants also comes from their unique dietary fiber and phenolic compounds.

The content of phenolic compounds is one of the most important factors that evaluate the health effects of plant foods. Antimutagenic, antidiabetic, and anti-inflammatory functions of plant products were highly related to the antioxidant capacity brought by the content of phenolic acids (Biglari et al. 2008; Vayalil 2002). Other polyphenols like procyanidins and flavonoids were also found in plants (Habib et al. 2014; Mansouri et al. 2005). Nonetheless, as Hong et al. (2006) mentioned in their work, due to different stages of maturity, the presence and concentration of some of the glycosylated flavonoids and procyanidins may also be different. Therefore, the measurement of phenolic compounds in plants is necessary to make the best use of plants.

Phenolic compounds in plants

Four main branches of polyphenols can be found in plant foods, which can be classified as flavonoids, stilbene, lignin, and phenolic acids based on their structure differences, phenol ring numbers, and molecular linkage type (Manach et al. 2004). Polyphenols provide antioxidant capacity which has many health effects such as assisting the human body to achieve better glycemic control, hypotensive, and increasing lipid profile (Li et al. 2015; Rodrigo et al. 2008; Zemestani et al. 2016). The antioxidant capacity of polyphenols is also expressed in the form of inhibiting the oxidative process by scavenging free radicals and reactive oxygen species which can help prevent oxidative stress diseases including cancer and diabetes (Ademiluyi and Oboh 2013; He and Sun 2016).

Phenolic acid is one of the main types of phenolic compounds present in plants. Scientists have already found a high concentration of phenolic acids in plants’ seeds, skins, and leaves which are present in bound form. Usual form of phenolic acids is found in amides, esters, and glycosides forms but seldom in free form (Pereira et al. 2009). According to the research done by Clifford (1999), hydroxybenzoic acid and hydroxycinnamic acid are the two sub-groups of phenolic acids. Hydroxycinnamic acids are often present in food as simple esters with quinic acid and glucose. Hydroxybenzoic acids are derived from benzoic acid and are found in soluble form and bound with cell wall fractions such as lignin (Khoddami et al. 2013; Strack and Dey 1997).

Flavonoid is a kind of secondary metabolite that is also rich in plants and contributes to the color, fragrance, and flavor characteristics of plants (Maleki et al. 2019). Due to the presence of hydroxy groups in flavonoids’ chemical structure, the bioavailability and biological activity in human body can be affected. The basic chemical structure of flavonoids is two benzene rings (A and B) linked by a three-carbon pyran ring (C). Due to the position of the B-ring and the position and number of hydroxy groups on it, the antioxidant capacity of flavonoids can be different (D’Amelia et al. 2018). The mechanism of the chemical reaction of flavonoid antioxidant protection is achieved by the donated electrons through resonance from functional hydroxy groups to stabilize free radicals (Šamec et al. 2021). Flavonoids have been widely applied in food and pharmaceutical industries due to their outstanding antioxidant capacity (Kumar and Pandey 2013). However, the industrial use of flavonoids and other phenolic compounds requires high-quality extractions. Therefore, the extraction methods have been developed to increase the production and more in line with the requirement of environmentally friendly (Rodríguez De Luna et al. 2020).

Previous studies have reported that the antioxidant capacities of plant seeds and peel are higher than pulp which is because most phenolics and flavonoids are stored in plant seeds and peel (Alharbi et al. 2021). But the seeds and peel are often discarded during product processing which seems to be a waste of high content of antioxidant compounds. Therefore, to effectively use plant wastes, efficient methods should be applied to extract the high content of phenolic compounds from food wastes.

Extraction methods

Phenolic compounds exist in plants in the form of glycosides or aglycones, and due to the stability differences, they can also exist as matrix and free-bound compounds. The structure differences can also affect the existence of phenolic compounds making them exist in the form of polymerized or monomers. Phenolic compounds are not universally distributed in plants with different stability which makes the extraction of these compounds more challenging (Alara et al. 2021). Single-step extraction and unsuitable extraction methods may influence the recovery rate of phenolic compounds from plant samples. Therefore, suitable extraction method selection is of vital importance for recovering the target phenolic compounds. To have a deeper understanding of extraction methods for obtaining phenolic compounds from plants, this review will focus on extraction methods that have been widely used which are listed in Table 1.

Conventional extraction

Maceration is a conventional extraction that has been widely applied to extract phenolic compounds from plants. Conventional extraction is a technique that uses the law of similarity and inter-miscibility (like dissolves like) to transfer target chemicals into the solvent (Zhang et al. 2018). In maceration extraction, ethanol or methanol is often selected as a solvent for phytochemical investigation which could extract the organic phenolic compounds from the plant samples. To accelerate the extraction progress, a shaking incubator is often used for shaking and temperature control which can increase the extraction rate by increasing the contact surface between samples and solvent. As Zhang et al. (2018) mentioned in their work, higher temperature can increase solubility and diffusion but avoid overheating is also important because if the extraction temperature is too high, the solvent will be lost and phenolic compounds will decompose. A successful example of applying conventional extraction was done by Saafi et al. (2009) using 50% methanol as a solvent to extract phenolic compounds from plants under room temperature. Their extraction process was assisted with an orbital shaker at a frequency of 200 rpm. As a result, the samples they tested were found rich in total phenolic, ranging from 209.42 to 447.73 mg equivalent gallic acid⁄100 g (GAE/100 g) fresh weight.

The extraction efficiency of conventional extraction depends on the extraction duration in a certain time range. Higher extraction duration brings higher efficiency but when a solute equilibrium is achieved between inside and outside solid matter, increasing time will not affect the extraction. To obtain a higher extraction yield, a greater solvent-to-solid ratio is required but when the solvent-to-solid ratio is too high, excessive extraction solvent will be used and requires a long time for extraction. As a result, conventional extraction methods usually use organic solvent maceration which requires a large volume of solvents and long extraction time which is stable but not efficient enough. Granulometry is another important factor that affects extraction efficiency. According to the research done by Mukhopadhyay et al. (2006), the total phenolic contents of black cohosh with four particle sizes (2 mm, 0.85 mm, 0.425 mm, and 0.250 mm) were measured, and the results showed the highest values were obtained from black cohosh with particle size range from 0.25 to 0.425 mm. The reason for this phenomenon is the surface area per unit mass of the plant increases while the particle size decreases which allows more phenolics to release.

Ultrasonic-assisted extraction (UAE)

To shorten the time required for extraction and increase the extraction quality, ultrasound is used in the solvent-producing cavitation which can bring high shear forces. Micro-jetting will be caused by the implosion of cavitation bubbles when ultrasonic is applied and will cause surface peeling, erosion, and particle breakdown, as do macro-turbulences and micro mixing (Chemat et al. 2017). As a result, it accelerates the dissolution and diffusion of the solute as well as the heat transfer. Compared with conventional extraction, UAE requires less solvent but a shorter extraction time.

Although, stronger ultrasonic applied to materials will create a greater shear force which can accelerate the changes. But due to cost considerations, ultrasonic applications in food industries are usually optimized to achieve the best result with the lowest energy usage (Bermúdez-Aguirre et al. 2011). To achieve the highest efficiency of extraction, increasing ultrasound power, reducing the moisture content in food materials, and temperature control are often considered. And the frequency of ultrasound must be selected properly because it can affect the size of bubbles produced during resonance.

Commonly, the frequencies applied in UAE processes range from 20 to 100 kHz. And for phenolic compounds, Chukwumah et al. (2009) reported changing the frequency can achieve the effect of molecule selection, for example, daidzein and genistein can be extracted at 25 kHz and biochanin A and trans-resveratrol can be extracted at 80 kHz. For regular extraction, 40 kHz was the most suitable frequency. González-Centeno et al. (2014) used the response surface methodology for the study of influencing parameters; the authors tested three frequencies (40 kHz, 80 kHz, and 120 kHz) for grape pomace phenolic compound extraction and found 40 kHz was the most effective. This was also approved by the study done by Almusallam et al. (2021); the optimum UAE condition was found under frequency 40 kHz, temperature 40.8 °C, duration 21.6 min, and ethanol concentration 50.0% which could extract the highest total phenolic content of 130.2 mg GAE from date palm spikelets.

Reflux extraction

Reflux extraction, also called solvent recycling reflux extraction, is an extraction method that extracts and concentrates the solvent simultaneously (Chen et al. 2013). Reflux extraction is divided into two parts, extraction tank and concentration tank. During the extraction process, the solvent in the extraction tank is pumped out into the concentration tank. In the concentration tank, solvent will be heated until evaporated then condensed and pumped back into the extraction tank. After repeating this process, the extracts in the solvent will be accumulated. Reflux extraction compared with conventional extraction has many advantages including shorter extraction time due to higher mass transfer driving force, less solvent cost due to solvent reuse, and lower fixed investment due to no requirement of a storage tank before concentration (Zhao et al. 2011). However, reflux extraction also has its disadvantages. Due to the requirement of concentration in reflux extraction and heating, phenolic compounds may be contaminated during evaporation or decompose at high temperatures.

Reflux extraction compared with conventional extraction has some advantages but it cannot be a substitute for conventional extraction. Habchi et al. (2021) studied phenolic compound extraction using the reflux method, and the total phenolic content was found to vary from 8.04 and 46.81 mg GAE/100 g dry weight. According to the research done by Kongkiatpaiboon and Gritsanapan (2013), in Stemona collinsiae Craib roots extraction, refluxing with 70% ethanol was the most recommended method which could obtain the highest yield of didehydrostemofoline. Also, an investigation of comparing conventional and reflux extraction methods showed no matter what solvent was used for extraction, reflux extracts had a higher extraction rate. But contrary to the extraction rate, higher total phenolic content and antioxidant capacity were obtained by conventional extraction (Sultana et al. 2009).

Microwave-assisted extraction (MAE)

MAE is an extraction method using microwave energy to heat solvents containing samples, thereby partitioning phenolic compounds from a sample matrix into the solvent. Compared with conventional extraction, selective migration of target compounds could be transferred from materials to surroundings within a shorter time by highly localized temperature and pressure generated during MAE. In addition, the recoveries of MAE are similar or even higher than conventional extraction while the space requirement, time requirement, and solvent requirement are all lower. The achievements of applying MAE in plant phenolic compound extractions have been reported by researchers (Chen et al. 2007; Hao et al. 2002; Hemwimon et al. 2007; Pan et al. 2002).

Similar to conventional extraction, in MAE, only the microwave heating effect can increase the product recovery (Spigno and De Faveri 2009). Although microwave heating is faster than conventional heating which saves time, the energy cost during this process may be higher. Therefore, the comparison of UAE and conventional extraction should bring the punctual energy cost into consideration as electricity is one of the most expensive energy forms. However, if the penetration depth characteristic for the solvent is larger than the sample size, MAE will lead to a dramatic increase in the heating rate that causes super boiling (Spigno and De Faveri 2009). Therefore, when transforming the laboratory scale results of MAE into industrial scale, the solvent and sample size need to be carefully considered to avoid false results and safety problems.

Soxhlet extraction

Compared with other conventional methods that appear in phenolic compound extraction, Soxhlet extraction requires less solvent and time while the processing cost is also very low. In addition, the extraction device is easy to operate and is suitable for initial and bulk extraction with a good recovery rate (Seidel 2012). Soxhlet extraction is an improved method based on reflux extraction which also integrates the advantage of percolation. Due to reflux and siphon, the fresh solvent can be recycled to extract materials continuously. Soxhlet extraction is automatic, and compared with conventional extraction, the solvent and time required for Soxhlet extraction are less. But Soxhlet extraction is a thermal extraction that may cause thermal degradation during a long extraction time when heating.

Successful examples of phenolic compounds extraction with the Soxhlet method were done by Alara et al. (2018), the highest yields of Soxhlet extraction from Vitis cinerea (Engelm.) Engelm. ex Millardet. leaves were obtained using 60% ethanol. Soxhlet extraction as Aspé and Fernández (2011) mentioned in their study had the highest extraction rate compared with MAE, UAE, and conventional extraction. But compared with UAE and MAE, the time required for Soxhlet to achieve the same extraction quality is longer. Soxhlet extraction can obtain a higher total phenolic and tannin content than conventional extraction but the following example showed that if treated with more stages, the phenolic compounds may decompose due to the high temperature. Ouahida et al. (2016) showed that after 6 h of extraction in 70% acetone, 528.81 mg GAE/g of total phenolic content was observed from date leaves. The result was higher than conventional extraction (484.44 mg GAE/g) but lower than UAE (625.17 mg GAE/g).

Pressurized liquid extraction (PLE)

Common processing of PLE is handled by packing solid samples into a steeled container and filled with extraction solvents then extracted for 5 to 15 min under high temperature and pressure. Due to high pressure, solvents can remain in liquid form at a temperature above their boiling point during PLE which makes the lipid solutes in the solvent in a high solubility and diffusion rate and allows easier penetration of the solvent into the matrix. Compared with conventional extraction, PLE also can decrease the requirement of solvent and time and have better repeatability.

PLE has been widely applied by many scientists to extract natural products like anthocyanin and saponins (Ju and Howard 2003; Zhang et al. 2018). PLE compared with conventional techniques requires same or even lower volume of solvents, and PLE is time-saving but does not need much handling of the sample (Alonso-Salces et al. 2001). Katsinas et al. (2021) mentioned in their work, that by comparing the extraction effect of conventional extraction and PLE, they found that compared with conventional extraction, PLE reduced by 67% extraction time and 38% solvent while the phenolic production increased.

However, as mentioned above, the mechanism of PLE is allowing solvents to remain in liquid form at high pressure and temperature to enhance the extraction rate but this may cause heat degradation. Therefore, Ju and Howard (2003) recommended extraction solvents that are not so efficient at low temperatures like water can be combined with PLE to increase its efficiency.

Supercritical fluid extraction (SFE)

SFE is an extraction method that applies supercritical fluid (SF) as its solvent for extraction. SF is an ideal solvent that has a similar solubility to liquid while the diffusivity is similar to gas making it able to dissolve a wide range of natural materials. However, SF is sensitive; the solvating properties of SF may change a lot near their critical points caused by small pressure and temperature changes. One of the typical SF used in extraction is supercritical carbon dioxide (S-CO2) which has been widely used. The advantages of using S-CO2 include low critical temperature (31 °C), selectivity, inertness, and nontoxic can extract compounds that are liable under high temperatures. S-CO2 is an ideal solvent for non-polar materials extraction like lipids due to its low polarity and can be enhanced its solvating properties by adding a modifier. However, to extract phenolic compounds with SFE, co-solvents are often required to increase the solubility of phenolic compounds (especially phenolic acids including gallic acid, methyl gallate, and caffeic acid) in the solvent. Radzali et al. (2020) studied the effect of different co-solvents (ethanol, water, methanol, 50% ethanol–water, and 70% methanol–water) used in SFE by testing the antioxidant capacity of their extracts and found that 70% ethanol–water co-solvent was efficient in increasing the extraction quality of SFE.

Phenolic compounds which are often extremely sensitive to the environment, temperature, oxygen, and light may become the reason for degradation which is not expected. So, compared with conventional extraction methods, SFE is a relatively clean extract that avoids oxidation that causes phenolic compound degradations. (Bleve et al. 2008; Vatai et al. 2009). However, the high cost of SFE is a reason it is not widely applied. Therefore, SFE is mainly used for products with high value (Sunarso and Ismadji 2009).

SFE was proven by Liu et al. (2013) as an effective method that could be used for phenolic compound extraction. Factors that can affect extraction efficiency include temperature, pressure, number of extractions, and extraction time. And for the total phenolic content obtained by SFE is mainly affected by the number of extractions. The best processing method of SFE is considered 2 h at 50 °C with 350 bar pressure for each time of extraction. The extraction quality was also compared by Ashfaq et al. (2021); in their research, they compared the extraction quality of SPE and conventional extraction from tea and use the extracts as coriander sauce preservatives. The total polyphenol content of SPE extracts (224.40 GAE/100 mL) was higher than conventional extraction extracts (208.31 GAE/100 mL), and similar situations also occur in a series of antioxidant assays.

Pulsed electric field extraction (PEF)

PEF is a non-thermal extraction method that applies short, high voltage pulses to destroy membrane structures and release the content which increases the extraction yield. Several factors may affect the efficiency of PEF including field strength, specific energy input, pulse number, and temperature.

Intact cytomembrane present in plant cells acts as a semipermeable barrier that controls the substances in or out of the cells. Therefore, PEF treatment is a method that could disintegrate the cell membrane and further increase the permeability of the cell wall to allow more bioactive compounds released into the solvents. Due to the structural disintegration of the cytomembrane of the cell, the selective permeability properties will be destroyed which allows more substance to come out during extraction. In addition, this process does not require heating and does not generate much heat which avoids thermolabile compounds’ degradation (Puértolas et al. 2012).

Liu et al. (2018) reported in their study the extraction of phenolic compounds from red onion was conducted at an electric field intensity range from 0.7 to 2.1 kV/cm and treatment times from 30 to 90 pulses under 25 °C. As a result, the extractions of phenolic compounds and flavonoid compounds were increased significantly when the electric field intensity and treatment of time increased. Liu et al. (2018) compared PEF‐assisted water with Soxhlet extraction and found the extraction yield of phenolic compounds and flavonoid compounds of PEF was only 1/3 and 1/2 of Soxhlet extraction, respectively. In addition, PEF also has its disadvantages which include the reversibility of the membrane changes, air bubbles making the process less effective, and the efficiency of the method depending on electric field strength and electrode gap (Joannes et al. 2015).

Enzyme-assisted extraction (EAE)

Enzymes can hydrolyze the components of the membranes in cells which break their selective permeability properties and release the compounds to increase the extraction rate. The structure of the cell membrane is mainly formed by macromolecules polysaccharides and proteins, and under high-temperature, proteins will denature which will affect the extraction efficiency. Therefore, enzymes like cellulase are applied in extraction as a nonthermal and nontoxic treatment to increase extraction efficiency.

In the old tea leaves extraction experiment done by Hai et al. (2016), they found that compared with samples treated with cellulase, the untreated group has a lower total polyphenol content. And when the concentration of enzyme increased, they found the total polyphenol content also increased and reached a peak of 74.45 mg GAE/g at 2%v/w of enzyme concentration. But when the cellulase concentration raise even further, the total polyphenol level and the polyphenol purity decrease. The reason for this phenomenon may be caused by excessive enzyme-hydrolyzed cell wall polysaccharides which release more impurities that decrease the total polyphenol content and purity (Baye et al. 2015).

However, compared with the chemical- and physical-assisted extraction methods, EAE is more complicated. To obtain extracts of high quality, EAE requires a detailed understanding of the samples including the composition and the enzyme that could be applied for helping extraction. Also, enzyme as a biological protein, its activity is affected by many factors, including pH, temperature, and substrate concentration.

Separation and characterization

The extracts obtained from the methods mentioned above are complex and contain a variety of natural materials and impurities that require separation to obtain the target chemical. Based on the physical and chemical differences of different compounds, modern technology has enough capabilities to separate them from the extracts.

Generally, to extract phenolic compounds, scientists and industries will choose solvent extraction which produces a mixed product that needs separation to improve its quality. Due to the characteristic of the target compound and the use of the final product, the separation method needs to be carefully selected. Commonly, separation is a purification method for obtaining purified compounds which is often combined with characterization methods to figure out different compounds. In food industries, separation methods can also be used for component quantification to figure out the nutritional list. For phenolic compounds, their biological effects especially the antioxidant effect can be tested by the separated compounds in animal testing. It is also a requirement to separate and purify the extracts, because during testing, the characterization of different compounds may affect each other and lead to a false result.

The basic method of separation is centrifugation which is a way of simulating multiple gravities with a high-speed rotation that can separate impurities from extract in the form of precipitates (Escribano-Bailon 2003). Ultrafiltration is another method that could be applied in phenolic compound separation, but due to the mechanism of ultrafiltration being based on particle size, it also has its limitations when the particle size does not match the filtration membrane size (Ajila et al. 2011). The concentration of extracts is often done in rotary evaporator to purify and separate the specific compound from extracts. And phenolic compounds in the mixture can be separated by solvent separation methods and chromatographic methods.

Membrane filtration (MF)

In most cases, the supernatant collected after centrifugation is still complex and diluted which needs to be concentrated and separate target phenolic compounds from it. But due to the existence of some heat-sensitive compounds like phlorotannins, scientists and industries cannot always evaporate the extracts. Therefore, membrane filtration (MF) is used as a nonthermal separation method that allows concentration at low temperatures. The principle of MF is using a semipermeable membrane which allows smaller molecules to pass through and block larger molecules. Due to the pore size applied, MF can be classified as microfiltration, ultrafiltration, and nanofiltration. Most phenolic compound studies applied MF as the first rough concentration of extracts (El-Mergawi et al. 2016; Giusti et al. 2019; Saleh et al. 2011) which have been proved to be very efficient phenolic compound classification.

According to the study done by Paraskeva et al. (2007), MF could separate phenolic compounds easily from olive mill wastewater. After further concentration, they obtained a concentrated phenolic product of 28 g/L GAE. But they found the product is unable to be further concentrated due to the high viscosity. Membrane is an easy-applying method but it still has its limitations. According to the studies done by Lu et al. (2011), the affinity for membranes of phenolic compounds and the membrane material characteristics may lead to quantitative and qualitative differences. These differences are affected by the molecular size and the solute structure differences which can control the retention. For example, compounds with larger size and less polar like pectin and protein can occasionally pass through the membrane pore and keep a moderate retention percentage while smaller and more polar compounds like phenolic acids, stilbenes, and sugars may gather at the membrane surface causing a 60% raise of rejection percentage. Yammine et al. (2019) mentioned in their work that to separate phenolic compounds with smaller sizes like monomeric, polymeric proanthocyanidins, and anthocyanins, thinner membrane film could be applied.

Solid-phase extraction (SPE)-GC/LC (gas chromatography/liquid chromatography)

SPE is a separation method that allows extracts to pass through a solid stationary phase to separate the desired compounds due to their affinity. To separate, concentrate, and clean-up, SPE is often used and compared with other separation methods; the time required for SPE is shorter, and the recovery rate is relatively higher while the SPE is easy to operate; if organized properly, the device even has the possibility of automation. Disposable cartridges are often used in modern SPE devices, but due to the high price of disposable cartridges, the processing is considered low reproducibility, and the flow rate is hard to control during elution. SPE disks are designed as a substitute for cartridges which use less solvent than cartridges when the elution is performed directly by the mobile phase. SPE disks can decrease evaporation to dryness and reconstitution which allows the extraction process more controllable. However, SPE disks are also very expensive even higher than cartridges (Nováková and Vlčková, 2009).

As a pre-treatment of chromatographic analysis, SPE can be directly combined with the analysis devices composed of SPE-LC or SPE-GC. According to the introduction from Xing et al. (2007), the analysis device once optimized with SPE can offer higher speed, lower detection limits, and better reproducibility and separate methods. And Lu et al. (2011) mentioned an improvement of online SPE-LC–MS/MS which uses multiwalled carbon nanotubes as SPE sorbents for the analytes’ online extraction and clean up. Mencin et al. (2021)reported a successful application of SPE with LC–MS; they compared SPE with liquid–liquid extraction and found higher extraction efficiencies of total and individual phenolics and also higher antioxidant activities in SPE method. Similarly, Liberatore et al. (2001) showed that the SPE technique can be successfully used for the extraction and quantitation of phenolic compounds in virgin olive oils, and the extracted compounds could be further characterized after analyzed by GC–MS.

Liquid chromatography–mass spectrometry (LC–MS/MS)

The principle of LC is based on the affinity differences of compounds which affect the interactions of compounds with the mobile and stationary phases. Then the compounds will be eluted off the column then transformed into gas phase and ionized for mass analysis. By converting the molecules to an ionized state then based on their mass to charge ratio (m/z), the mass spectrometers can analyze the ions and any fragment ions that are produced during the ionization process. This is a typical mass spectrometer’s working principle by combining an ionization device with an ion analysis device (Pitt 2009).

For phenolic compound analysis, liquid chromatography with tandem mass spectrometry (LC–MS/MS) have been proven to be effective at low quantification limits. So, we can conclude that LC–MS/MS is one of the most reliable methods for phenolic compound characterization. But due to the precision of the instrument of LC–MS/MS, this method also has its limitations. If the instrument is contaminated, the operator may not be able to find the problem and leading to a false result. And due to the high price of the instrument, LC–MS/MS is not easy to popularize. Because the selection of analytical methods is based on the matrix and the characteristic of phenolic compounds, LC–MS/MS cannot suit all analytical situations. Successful applications of LC–MS/MS were widely mentioned by many researchers, including the characterization of phenolic compounds in custard apple fruit done by Du et al. (2021) who successfully characterized 85 phenolic compounds; Chou et al. (2021) identified a total of 73 compounds, 11, 31, and 49 kinds of unique phenolic compounds in ginger, lemon, and mint respectively by LC-ESI/QTOF-MS; 80 phenolic compounds were identified from chicory and lucerne (Iqbal et al. 2021); A total of 84 phenolic compounds were identified through LC–MS/MS in Australian grown herbs (Ali et al. 2021).

Gas chromatography–mass spectrometry (GC–MS)

The basic principle of GC–MS is similar to LC–MS/MS; the main difference is the mobile phase used in the system. Due to the high efficiency and fast separation of gas chromatography (GC), GC is considered an ideal method for phenolic compound separation and characterization. James and Martin (1952) first described this method as a separation method for small carboxylic acids mixture. Different from LC, the mobile phase in this method is a gas stream which is also called carrier gas. This method experienced a long development; packed-columns were first used in this method, but after small carboxylic acids were introduced into GC, the power was improved significantly which was first made by glass; but in 1976, glass was replaced by fused-silica capillary columns which was a great improvement of GC (Niessen 2001).

Zhang and Zuo (2004) applied GC–MS in phenolic compound classification in cranberry juice and plasma after consuming cranberry juice. According to their studies, sixteen phenolic compounds were identified in cranberry juice while in plasma samples, only a few benzoic acids and phenolic acids could be found. The advantage of this method includes sensitivity, specificity, and good repeatability which can be also used for phenolic compound antioxidant measurement.

High-performance liquid chromatography (HPLC)

HPLC is a separation and characterization method that has been widely accepted by many scientists and is a useful tool for phenolic compound analysis other than LC–MS and GC–MS. Commonly, HPLC is combined with different detectors to analyze phenolic compounds such as ultraviolet–visible (UV) and photodiode array detector (PDA). A large group of phenolic compounds and their derivatives were characterized in previous studies through HPLC and assisted the researchers in identifying the phenolic classes in plants.

HPLC consists of three parts, which include a column which is a stationary phase, a pump that drives the movement of the mobile phase, and a detector that collected data (Martin and Guiochon 2005). The mechanism of retention time in HPLC is similar to LC–MS and GC–MS which depends on the interaction between mobile and stationary phases (Xiang et al. 2006). Common solvents used in this method are a combination of water and organic liquids like acetonitrile. Varied mobile phase composition during analysis is known as gradient elution which is aimed at separation (Abidi 1991; Xiang et al. 2006). As Abidi (1991) mentioned in his work, the gradient that separates the compounds is also based on the difference in affinity with the mobile phase of different compounds. Therefore, due to the characteristic of the stationary phase and the analyte, the solvents and gradient dependencies could be decided. Research on mangiferin quantification was done by Imran et al. (2016), and in this study, HPLC was successfully used and obtained the variety of mango with the highest mangiferin content among the five tested varieties of mangoes.

Capillary electrophoresis (CE)

CE compared with HPLC is a relatively new separation method that has the potential to become an alternative to HPLC and become a wider used method for phenolic compound characterization methods. As Skoog et al. (2017) mentioned in their work, CE is an analytical separation method that uses an electric field to separate the components of a mixture. It is electrophoresis in a capillary, a narrow tube. Hence, the components of the mixture are separated based on their electrophoretic mobility. Only the ions are affected by the electric field while the neutral species remain unaffected. The rate of a molecule that moves through the capillary depends on the strength of the electric field. The analytes separate as they migrate due to their electrophoretic mobility, and are detected near the outlet end of the capillary where a detector is often set. The output of the detector is sent to a data output and handling device such as an integrator or computer. The data is then displayed as an electropherogram, which reports detector response as a function of time. Separated chemical compounds appear as peaks with different migration times in an electropherogram.

As Tsao and Deng (2004) mentioned in their studies, CE is a separation method with more advantages than HPLC, which include the sample size required for CE being smaller than HPLC, non-parabolic fronting bringing CE higher efficiency, the time required for analyzing is shorter, low cost, and low or no requirement of organic solvent.

Countercurrent chromatography (CCC)

Countercurrent chromatography is a separation method that moves two liquid phases with respect to one another to form a liquid–liquid chromatographic system not requiring a solid support (Ito and Bowman 1970). This method was first introduced by Ito and Bowman (1970) in the late 1970s and has been widely used for phenolic compound separation and purification. The mechanism of CCC is based on the compound distribution between two immiscible liquids which are called mobile phase and stationary phase, respectively. The previous report mentioned that CCC does not have several band-broadening mechanisms caused by the action of random imperfection in the flow stream like conventional chromatography because CCC does not have a solid support matrix in the column (Wang et al. 2015). Therefore, CCC has a less complex mathematical description of the separation process than conventional liquid–liquid chromatography because in the conventional case, the liquid stationary phase is retained on a solid support.

CCC has been used for the separation of phenolic compounds from plants. He et al. (2009) reported a successful application of high-speed CCC for the preparative isolation of the minor phenolic compounds from the ethyl acetate extracts of black currant fruit. In their study, high-speed CCC separation was performed with a two-phase solvent system composed. As a result, 0.8 mg of protocatechuic acid, 1.0 mg of caffeic acid, 0.5 mg of 4-hydroxybenzoic acid, and 2.5 mg of myricetin were separated from a total of 500 mg crude sample by a one-step high-speed CCC operation.

Centrifugal partition chromatography (CPC)

Centrifugal partition chromatography is a developed method of CCC which was introduced by Murayama et al. (1982). CPC is a type of hydrostatic countercurrent chromatography and like other same types of methods which are based on the phenomenon of liquid–liquid partitioning between two immiscible liquid phases that stay at equilibrium. But in the case of CPC, the mechanism of stationary phase retention is significantly different from others; the centrifugal field in the rotor in a one-axis centrifuge generates hydrostatic force to conduct stationary phase retention (Bojczuk et al. 2017). However, the efficiency of the separation in CPC is affected by a variety of parameters which include the sample properties in the solvent system, physical properties of the solvent system, parameters of the instrument, and the method. CPC does not need an expensive solid stationary phase, and compared with conventional CCC separation methods, both the quantity and quality requirements regarding the solvents/phases to be used could be much more similar in terms of their properties (Santos et al. 2018).

In previous studies, in order to purify caffeic, ferulic, and protocatechuic acids, CPC was applied and achieved an efficient separation of the three phenolic acids (Santos et al. 2018). Alherech et al. (2021) also reported in their study that CPC is an effective technology that could provide scalable access to valuable chemicals from lignin and other biomass-derived feedstocks.

Phenolic content and antioxidant activity determination methods

To test the phenolic contents and the antioxidant capacity of plant samples, a series of antioxidant assays were applied. The most concerning values are the phenolic content in plants. Therefore, the phenolic, flavonoids, and condensed tannins content were often tested in many studies. And to test the antioxidant capacity of plant extracts, assays including DPPH test are also useful tools in many pieces of researches.

Total phenolic content (TPC)

To evaluate the health value of plants, the TPC value can be an important indicator (Khomdram and Singh 2011). Factors including extract volume, reagent selection, reaction time, color development temperature, measurement wavelength, and reference substance may affect the TPC values (Abdelkader et al. 2014).

The principle of measuring the TPC in plant materials is based on the color change reaction between polyphenols and Folin-Ciocalteu reagent (FCR) which can form a blue complex then can be quantified by instruments like spectrophotometric microplate reader (Abdelkader et al. 2014; Agbor et al. 2014). As Agbor et al. (2014) mentioned in their study, the blue complex is a phosphotungstic-phosphomolybdenum complex. And due to the alkaline solution and the concentration of phenolic compounds, absorbance of this matrix will be different which makes the quantification of phenolic compound concentration available (Blainski et al. 2013). FCR is a very sensitive and accurate method which has been proved by several scientists that it can provide accurate and specific data for TPC measurement as color responses were common and intuitive in their research (Fig. 1) (Agbor et al. 2014).

Principle of Folin–Ciocalteu method (Ford et al. 2019)

Total flavonoids content (TFC)

The flavonoid content in plant materials is also an important parameter in evaluating plants’ nutritional value. So, to test the TFC of plant materials, Al-flavonoid complexation method is often applied. In 1960, the original method was designed by Christ and Müller (1960) for herbal materials-analyzing purposes, and after many years of modification, it becomes the modern form. There are two main procedures for applying Al-flavonoid complexation reaction. Commonly, a concentration of 2–10% (m/v) AlCl3 solution is added to a sample then measure the absorbance at 404–430 nm after 2–60 min, and different flavonols like quercetin or galangin and flavan-3-ol catechin can be used as equivalent standard. The other procedure was a o-diphenol determination method used by Barnum (1977); the method is based on the color change of aromatic ring bearing a catechol group with Al (III) which is an orange complex and will turn pink-red when added NaOH. Then the absorbance can be measured with instruments like a spectrophotometric microplate reader at 510 nm (Fig. 2).

Formation of flavonoid complex with AlCl3 (Shraim et al. 2021)

Total tannins content (TTC)

To test the TTC in pant materials, the vanillin method is often applied due to its color complex formation mechanism. Factors that affect this reaction include solvent and reagent selection, concentration, reaction time, temperature, and the reference standard selection (Dalzell and Kerven 1998; Makkar and Becker 1993; Scalbert 1992; Sun et al. 1998).

In the vanillin assay method, sulfuric acid is the most often used catalyst but if the normality of acid is too high, the absorbance at 500 nm (A500) will also increase (Scalbert 1992; Sun et al. 1998). As Bae et al. (1993) and Sun et al. (1998) discussed in their work, the rise of water content can dramatically decrease the A500 in this test. Waterman and Mole (1994) and Sun et al. (1998) both mentioned the importance of temperature control in their work, and they also found an 11% increase of A500 can be obtained for each 1.4 °C increase in their research. However, the result of the research done by Sun et al. (1998) was not so severe, but they also mentioned that to achieve the highest absorbance, the TTC test should be conducted under 25–30 °C (Fig. 3).

The mechanism of vanillin assay for condensed tannins (Schofield et al. 2001)

The DPPH (2,2-di(4-tert-octylphenyl)-1-picrylhydrazyl) test

The DPPH test is a free radical scavenging activity testing method. The mechanism of reaction with antioxidants is a color change from a deep purple (DPPH•) to pale yellow (DPPH) after reaction with peroxyl radicals ROO• (Benzie and Strain 1999). DPPH• presents as a monomer in both solid and liquid states which can solve in organic solvents like methanol and ethanol to react with free radicals which are not soluble in water. As Staško et al. (2007) mentioned in their work, water content should be controlled below 60% to remain good solubility of radicals.

The DPPH radical is neutralized after accepting electrons from antioxidants, and due to the color change during this process, the antioxidant capacity can be quantified at 517 nm. There are two main ways of reporting the antioxidant activity measured by DPPH neutralization method which are EC50 (the concentration required for the antioxidant to reduce the initial DPPH concentration by 50%) and TEC50 (the time required for achieving the equilibrium state with EC50) (Foti 2015) (Fig. 4).

DPPH scavenging mechanisms (Dureja and Dhiman 2012)

Ferric reducing/antioxidant power (FRAP) test

FRAP test is an antioxidant capacity measuring method based on single electron transfer (SET) method to measure the reduction of ferric ions (Fe3+)-ligand complex to the intensely blue ferrous complex (Fe2+) (Antolovich et al. 2002). The absorbance is measured at 593 nm, and the antioxidant is positively related to the micromolar equivalents of Fe2+ in this test. But different from other SET-based methods, FRAP test requires a low pH environment to maintain iron solubility which decreases the ionization potential and increases the redox potential (Hagerman et al. 1998).

Tripyridyltriazine (TPTZ) was first used in FRAP test as an iron ion linking ligand, and the substitutes are also used for the same effect (Molina-Dıaz et al. 1998). For example, ferrozine is used for evaluating ascorbic acid’s antioxidant capacity. Potassium ferricyanide is the most common ferric reagent used in modern FRAP tests. Based on spectrophotometry, the reducing power of the tested material could be quantified after the blue color was generated. Generally, there are two principles of blue color formation that do not affect the result. The first one is after Fe3+ is reduced to Fe2+, it will bind with ferricyanide forming blue complexes. The second one is ferrocyanide reduced from ferricyanide can bind with Fe3+ to form the complexes (Fig. 5).

The mechanism of ferric reducing antioxidant power (FRAP) reaction (Munteanu and Apetrei 2021)

Ferrous ion chelating ability (FICA) assay

FICA assay is a test for antioxidant capacities and its principle is based on the transition metal ion chelating ability like Fe2+ and Cu2+. Ferrous chloride (FeCl2) is often used in this kind of determination test to provide Fe2+. The typical procedure of FICA test is first mixing the sample with FeCl2. Then the mixture after incubation will be added ferrozine to form color complexes in dark environment incubation. The absorbance will be measured at 562 nm. To quantify the chelating ability, ethylene diamine tetraacetate (EDTA) is used as a positive control.

Md Yusof et al. (2013) applied this test to measure the chelating ability of Pandanus pygmaeus. In their test, only the methanol extract of Pandanus pygmaeu and the EDTA group showed chelating ability. When they increased the sample concentration in extracts, the absorbance of ferrous and ferrozine complex decreased, which indicates the positive relation between chelating ability and sample concentration. As they reported, the peak of chelating activity is obtained at 10,000 µg/mL while the chelating percentage is at 85.39%. The chelating ability is expressed as an IC50 value in this test; lower IC50 value means the chelating activity is higher, and in the research done by Md Yusof et al. (2013), they found EDTA has a lower IC50 than the tested extract which means compared with EDTA, Pandanus pygmaeu extract is a moderated metal-chelating agent (Fig. 6).

The principle of ferrous ion chelating ability (FICA) assay (Santos et al. 2017)

The 2,2’-azino-bis-(3-ethylbenzothiazoline-6-sulfonic acid) (ABTS) radical scavenging assay

The ABTS radical scavenging assay is another method used for testing the antioxidant capacity of plant extract. In 1993, ABTS test was first applied by Miller et al. (1993) based on the principle of the interaction between antioxidants and ABTS+ which indicates the ability to scavenge free radicals. Due to a bluish-green color complex formed during this test, the activity can be quantified by measuring the absorbance at 734 nm, whose intensity decreases the strength of antioxidant capacity. Because of the presence of powerful antioxidant agents, ABTS can be transformed into ABTS+ which is the main factor that affects the degree of discoloration of the blue–green color, which will be reflected as absorbance decreases at 734 nm.

ABTS tests have been widely used for antioxidant capacity evaluation and for p-hydroxybenzoic acids and polyphenolic compounds (Solís-Oba et al. 2005). As Arnao et al. (1990) mentioned in their work, this method can also be used for some varieties of flavonoids by using peroxidase. However, both methods are based on the ABTS–polyphenol complex formation under enzymatic reaction. ABTS radical scavenging assay does not have a strict pH requirement which allows a wide range of evaluation and is beneficial for studying the pH effect on food components’ antioxidant mechanisms. In addition, ABTS radical is both water and organic soluble which make it able to evaluate the antioxidant capacity of oil and water-soluble components (Fig. 7).

The mechanism of ABTS radical scavenging activity assay (Xiao et al. 2020)

Hydroxyl radical scavenging activity assay (•OH-RSA)

•OH-RSA assay is an antioxidant testing method based on the Fenton reaction (Fe3+-ascorbate-EDTA-H2O2 system), which measures the hydroxyl radicals generated from hydrogen peroxide. In the presence of iron, hydrogen peroxide can process a set of reactions called the Fenton reaction which can generate hydroxyl radicals then scavenged by antioxidants. The quantification in •OH-RSA assay is conducted on malonaldehyde produced during the 2-deoxyribose degradation then condensed with thiobarbituric acid forming a yellow complex. This complex absorbance will be measured at 510 nm.

Testing the hydroxyl radical scavenging activity is meaningful, especially in the medical area. Free radicals can form under the Fe2+ existing environment which can be even driven by non-reactive radicals. Therefore, chelating Fe2+ can be an effective treatment of oxidative stress diseases. However, the toxicity of chelators also needs to be considered. Chelators may be toxic which requires a balance between the toxic damage and the positive effects of antioxidize effect. Franco et al. (2019) had already introduced the achievement of using antioxidants to protect red blood cells from oxidative damage which is based on the mechanism of chelators can form stable complexes with free radicals then excreted by feces and urine. But due to the serious side effect of most chelating agents, discovering potential chelators from natural ingredients is very valuable for scientists and may be less harmful to patients. Therefore, •OH-RSA assay for testing the hydroxyl radical scavenging activity of plant extracts is important which may help discover new free radical chelators (Fig. 8).

Fenton reaction mechanism (Salgado et al. 2013)

Reducing power assay (RPA)

RPA is a more general test of the antioxidant which was first described by Oyaizu (1986). The principle of the RPA test is based on the reduction ability of the phenolic compounds that could reduce the Fe3 +/ferricyanide complex to the ferrous form which changes from yellow to a green–blue color. Then the reducing power can be determined at the absorbance of 700 nm. This test needs to take special care with the heating process, with the test tubes partially closed, so that there is no solvent concentration process, and so it can be validated and determine the real concentration.

The RPA test was used by Martorana et al. (2013) based on the RPA method mentioned by Oyaizu (1986) to test the reducing power of pistachio extracts. They used methanol/water (2/1) solutions to extract phenolic compounds from pistachio then the extract was mixed with sodium phosphate buffer and K3Fe(CN)6 before an incubation under 50 °C. After incubation, trichloroacetic acid was added to the sample then centrifuged, and the supernatant was collected then added distilled water and ferric chloride solution. As a result, the formation of blue-green complex can be used for quantifying the reducing power of pistachio extracts at an absorbance of 700 nm. Ascorbic acid was used as an equivalent standard in their test, and the reducing power of the pistachio extracts was successfully tested as 1.13 mmoles AAE/g (seed) and 2.69 mmoles AAE/g (skin).

Total antioxidant capacity (TAC) test

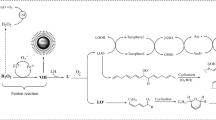

TAC test is a general test of the antioxidant capacity of plant extracts which Jayaprakasha et al. (2002) mentioned in their research as a phosphomolybdate method-based test using α-tocopherol as an equivalent standard. The test is performed by mixing the extracts with a special reagent which is a mixture of sulfuric acid, sodium phosphate, and ammonium molybdate. The mixture will then be incubated at 95 °C for 90 min, and the absorbance is measured at 695 nm after cooling. α-tocopherol will be also tested with the same procedures as a standard. As Jayaprakasha et al. (2002) reported, α-tocopherol can make a standard with good performance under the same conditions and was selected as the standard. Therefore, the TAC value can be expressed as µg equivalents of α-tocopherol.

Summary

As important raw materials, plants play a significant role in the medical and food area. Plants supplement human’s nutritional needs in their diet and can be widely used in the treatment of various diseases. The high content of phenolic compounds in some plants even raised a great interest from many scientists. The potential of applying the high antioxidant capacity of phenolic from plants might be valuable. Therefore, developing methods that could be used for phenolic compound extraction, separation, and characterization are meaningful to evaluate the nutritional value of these compounds. For extraction methods, the most commonly used method is still conventional maceration extraction which had been applied in most of the research in this area. However, to improve the efficiency of solvent extraction, techniques including ultrasonic, Soxhlet extraction, and enzymes are also applied. But due to the limitation of some methods, it is important to select the methods carefully to maximize the extraction efficiency of target components.

Considering the analytical methods used for phenolic compounds determination including HPLC, LC–MS, and GC–MS they all appeared to first separate the compounds from the extract and then analyze the characteristics of the compounds to classify them. Improvements in the characterization method of evaluating the chemical structures of these compounds have been developed over several decades, and the database of most phenolic compounds has been clarified which is beneficial for analyzing the phenolic in plants. Similarly, a series of assays have been developed for testing the content and the antioxidant capacity of phenolic compounds in plants. These methods are all considered to be reliable tools in chemical analysis of plants. However, although all of these methods are proven to be reliable in many plant extracts, some of them lack data on application to a wider variety of plants which is worth studying in the future. Current research of the phenolic compounds in plants and methods used for characterizing the phenolic types and testing their antioxidant capacities are considered to be a great starting point. But due to some of the methods having their limitations, it still requires further research to test the reliability of these methods applied to plant extracts.

Data availability

Not applicable.

References

Abdelkader M, Ahcen B, Rachid D, Hakim H (2014) Phytochemical study and biological activity of sage (Salvia officinalis L.). Int J Biol Biomol Agric Food Biotechnol Eng 8(11):1231–1235

Abidi S (1991) High-performance liquid chromatography of phosphatidic acids and related polar lipids. J Chromatogr A 587(2):193–203

Ademiluyi AO, Oboh G (2013) Soybean phenolic-rich extracts inhibit key-enzymes linked to type 2 diabetes (α-amylase and α-glucosidase) and hypertension (angiotensin I converting enzyme) in vitro. Exp Toxicol Pathol 65(3):305–309

Agbor GA, Vinson JA, Donnelly PE (2014) Folin-ciocalteau reagent for polyphenolic assay. Int J Food Sci Nutr Diet (IJFS) 3(8):147–156

Ajila C, Brar S, Verma M, Tyagi R, Godbout S, Valero J (2011) Extraction and analysis of polyphenols: recent trends. Crit Rev Biotechnol 31(3):227–249

Alara OR, Abdurahman NH, Ukaegbu CI (2018) Soxhlet extraction of phenolic compounds from Vernonia cinerea leaves and its antioxidant activity. J Appl Res Med Aromat Plants 11:12–17

Alara OR, Abdurahman NH, Ukaegbu CI (2021) Extraction of phenolic compounds: a review. Curr Res Food Sci 4:200–214

Alharbi KL, Raman J, Shin H-J (2021) Date fruit and seed in nutricosmetics. Cosmetics 8(3):59

Alherech M, Omolabake S, Holland CM, Klinger GE, Hegg EL, Stahl SS (2021) From lignin to valuable aromatic chemicals: lignin depolymerization and monomer separation via centrifugal partition chromatography. ACS Cent Sci 7(11):1831–1837

Ali A, Bashmil YM, Cottrell JJ, Suleria HAR, Dunshea FR (2021) LC-MS/MS-QTOF screening and identification of phenolic compounds from Australian grown herbs and their antioxidant potential. Antioxidants 10(11):1770

Almusallam IA, Ahmed IAM, Babiker EE, Al Juhaimi FY, Fadimu GJ, Osman MA, Ai Maiman SA, Ghafoor K, Alqah HA (2021) Optimization of ultrasound-assisted extraction of bioactive properties from date palm (Phoenix dactylifera L.) spikelets using response surface methodology. LWT 140:110816

Alonso-Salces RM, Korta E, Barranco A, Berrueta L, Gallo B, Vicente F (2001) Pressurized liquid extraction for the determination of polyphenols in apple. J Chromatogr A 933(1–2):37–43

Alves R, Rosa IM (2007) Biodiversity, traditional medicine and public health: where do they meet? J Ethnobiol Ethnomed 3(1):1–9

Antolovich M, Prenzler PD, Patsalides E, McDonald S, Robards K (2002) Methods for testing antioxidant activity. Analyst 127(1):183–198

Arnao M, Casas J, Del Rio J, Acosta M, Garcia-Canovas F (1990) An enzymatic colorimetric method for measuring naringin using 2, 2′-azino-bis-(3-ethylbenzthiazoline-6-sulfonic acid)(ABTS) in the presence of peroxidase. Anal Biochem 185(2):335–338

Ashfaq F, Bilal A, Butt MS, Tehseen S, Akhtar MN, Suleria HAR (2021) Comparing the application of conventional and supercritical CO2 extracts of green tea; storage stability and sensory acceptance of coriander sauce. J Food Process Preserv 45(12):e16058

Aspé E, Fernández K (2011) The effect of different extraction techniques on extraction yield, total phenolic, and anti-radical capacity of extracts from Pinus radiata bark. Ind Crops Prod 34(1):838–844

Bae HD, McAllister TA, Muir AD, Yanke LJ, Bassendowski KA, Cheng KJ (1993) Selection of a method of condensed tannin analysis for studies with rumen bacteria. J Agric Food Chem 41(8):1256–1260

Barnum DW (1977) Spectrophotometric determination of catechol, epinephrine, dopa, dopamine and other aromatic vic-diols. Anal Chim Acta 89(1):157–166

Baye K, Guyot JP, Icard-Vernière C, Rochette I, Mouquet-Rivier C (2015) Enzymatic degradation of phytate, polyphenols and dietary fibers in Ethiopian injera flours: effect on iron bioaccessibility. Food Chem 174:60–67

Benzie IF, Strain J (1999) [2] Ferric reducing/antioxidant power assay: direct measure of total antioxidant activity of biological fluids and modified version for simultaneous measurement of total antioxidant power and ascorbic acid concentration. Methods Enzymol 299:15–27

Bermúdez-Aguirre D, Mobbs T, Barbosa-Cánovas GV (2011) Ultrasound applications in food processing. Ultrasound technologies for food and bioprocessing, Springer

Biglari F, AlKarkhi AF, Easa AM (2008) Antioxidant activity and phenolic content of various date palm (Phoenix dactylifera) fruits from iran. Food Chem 107(4):1636–1641

Blainski A, Lopes GC, De Mello JCP (2013) Application and analysis of the folin ciocalteu method for the determination of the total phenolic content from Limonium brasiliense L. Molecules (basel, Switzerland) 18(6):6852–6865

Bleve M, Ciurlia L, Erroi E, Lionetto G, Longo L, Rescio L, Schettino T, Vasapollo G (2008) An innovative method for the purification of anthocyanins from grape skin extracts by using liquid and sub-critical carbon dioxide. Sep Purif Technol 64(2):192–197

Bojczuk M, Żyżelewicz D, Hodurek P (2017) Centrifugal partition chromatography—a review of recent applications and some classic references. J Sep Sci 40(7):1597–1609

Chemat F, Rombaut N, Sicaire A-G, Meullemiestre A, Fabiano-Tixier A-S, Abert-Vian M (2017) Ultrasound assisted extraction of food and natural products. Mechanisms, techniques, combinations, protocols and applications. A review. Ultrason Sonochem 34:540–560

Chen Y, Xie M-Y, Gong X-F (2007) Microwave-assisted extraction used for the isolation of total triterpenoid saponins from Ganoderma atrum. J Food Eng 81(1):162–170

Chen J, Liu Z, Wu M, Ke Y (2013) Optimization of extraction process of xinmaikang tablets by orthogonal test. Chin J Exp Tradit Med Formulae 19:59–61

Chen Y, Michalak M, Agellon LB (2018) Importance of nutrients and nutrient metabolism on human health. Yale J Biol Med 91(2):95–103

Chou O, Ali A, Subbiah V, Barrow CJ, Dunshea FR, Suleria HAR (2021) LC-ESI-QTOF-MS/MS characterisation of phenolics in herbal tea infusion and their antioxidant potential. Fermentation 7(2):73

Christ B, Müller K (1960) Zur serienmäßigen Bestimmung des Gehaltes an flavonol-Derivaten in Drogen. Arch Pharm 293(12):1033–1042

Chukwumah YC, Walker LT, Verghese M, Ogutu S (2009) Effect of frequency and duration of ultrasonication on the extraction efficiency of selected isoflavones and trans-resveratrol from peanuts (Arachis hypogaea). Ultrason Sonochem 16(2):293–299

Clifford MN (1999) Chlorogenic acids and other cinnamates–nature, occurrence and dietary burden. J Sci Food Agric 79(3):362–372

Dalzell SA, Kerven GL (1998) A rapid method for the measurement of Leucaena spp proanthocyanidins by the proanthocyanidin (butanol/HCl) assay. J Sci Food Agric 78(3):405–416

D’Amelia V, Aversano R, Chiaiese P, Carputo D (2018) The antioxidant properties of plant flavonoids: their exploitation by molecular plant breeding. Phytochem Rev 17(3):611–625

Du J, Zhong B, Subbiah V, Barrow CJ, Dunshea FR, Suleria HAR (2021) LC-ESI-QTOF-MS/MS profiling and antioxidant activity of phenolics from custard apple fruit and by-products. Separations 8(5):62

Dureja AG, Dhiman K (2012) Free radical scavenging potential and total phenolic and flavonoid content of Ziziphus mauritiana and Ziziphus nummularia fruit extracts. Int J Green Pharm 6(3)

Ekor M (2014) The growing use of herbal medicines: issues relating to adverse reactions and challenges in monitoring safety. Front Pharmacol 4:177

El-Mergawi R, Al-Humaid A, El-Rayes D (2016) Phenolic profiles and antioxidant activity in seeds of ten date cultivars from Saudi Arabia. J Food Agric Environ 14(2):38–43

Escribano-Bailon MT (2003) Polyphenol Extraction from Foods. Methods in Polyphenol Analysis, Royal Society of Chemistry, London, pp 1–12

Ford L, Theodoridou K, Sheldrake G, Walsh P (2019) A critical review of analytical methods used for the chemical characterisation and quantification of phlorotannin compounds in brown seaweeds. Phytochem Analy 30:1–13

Foti MC (2015) Use and abuse of the DPPH radical. J Agric Food Chem 63(40):8765–8776

Franco R, Navarro G, Martínez-Pinilla E (2019) Antioxidant defense mechanisms in erythrocytes and in the central nervous system. Antioxidants 8(2):46

Giusti F, Capuano E, Sagratini G, Pellegrini N (2019) A comprehensive investigation of the behaviour of phenolic compounds in legumes during domestic cooking and in vitro digestion. Food Chem 285:458–467

González-Centeno MR, Knoerzer K, Sabarez H, Simal S, Rosselló C, Femenia A (2014) Effect of acoustic frequency and power density on the aqueous ultrasonic-assisted extraction of grape pomace (Vitis vinifera L.)–a response surface approach. Ultrason Sonochem 21(6):2176–2184

Habchi A, Dekmouche M, Hamia C, Saidi M, Yousfi M, Bouguerra A (2021) Extraction of phenolic compounds of six algerian date (Phoenix dactylifera L.) cultivars from Ain-Saleh region, using reflux method and screening of antioxidant activity in vitro. Asian J Res Chem 14(3):161–167

Habib HM, Platat C, Meudec E, Cheynier V, Ibrahim WH (2014) Polyphenolic compounds in date fruit seed (Phoenix dactylifera): characterisation and quantification by using uplc-dad-esi-ms. J Sci Food Agric 94(6):1084–1089

Hagerman AE, Riedl KM, Jones GA, Sovik KN, Ritchard NT, Hartzfeld PW, Riechel TL (1998) High molecular weight plant polyphenolics (tannins) as biological antioxidants. J Agric Food Chem 46(5):1887–1892

Hai T, Nam N, Hong Anh L, Vu T, Man P (2016) Enzyme assisted extraction of polyphenols from the old tea leaves. J Nutr Health Sci 3(4):404–410

Hao J-Y, Han W, Xue B-Y, Deng X (2002) Microwave-assisted extraction of artemisinin from Artemisia annua L. Sep Purif Technol 28(3):191–196

He X, Sun L-M (2016) Dietary intake of flavonoid subclasses and risk of colorectal cancer: evidence from population studies. Oncotarget 7(18):26617

He D, Gu D, Huang Y, Ayupbek A, Yang Y, Aisa HA, Ito Y (2009) Separation and purification of phenolic acids and myricetin from black currant by high-speed countercurrent chromatography. J Liq Chromatogr Relat Technol 32(20):3077–3088

Hemwimon S, Pavasant P, Shotipruk A (2007) Microwave-assisted extraction of antioxidative anthraquinones from roots of Morinda citrifolia. Sep Purif Technol 54(1):44–50

Hong YJ, Tomas-Barberan F, Kader AA, Mitchell AE (2006) The flavonoid glycosides and procyanidin composition of deglet noor dates (Phoenix dactylifera). J Agric Food Chem 54(6):2405–2411

Imran M, Butt MS, Akhtar S, Riaz M, Iqbal MJ, Suleria HAR (2016) Quantification of mangiferin by high pressure liquid chromatography; physicochemical and sensory evaluation of functional mangiferin drink. J Food Process Preserv 40(4):760–769

Iqbal Y, Ponnampalam EN, Suleria HAR, Cottrell JJ, Dunshea FR (2021) LC-ESI/QTOF-MS profiling of chicory and lucerne polyphenols and their antioxidant activities. Antioxidants 10(6):932

Ito Y, Bowman RL (1970) Countercurrent chromatography: liquid-liquid partition chromatography without solid support. J Chromatogr Sci 8(6):315–323

James AT, Martin AJ (1952) Gas-liquid partition chromatography: the separation and micro-estimation of volatile fatty acids from formic acid to dodecanoic acid. Biochemical Journal 50(5):679

Jayaprakasha GK, Jena BS, Negi PS, Sakariah KK (2002) Evaluation of antioxidant activities and antimutagenicity of turmeric oil: a byproduct from curcumin production. Z Naturforsch C 57(9–10):828–835

Joannes C, Sipaut CS, Dayou J, Yasir SM, Mansa RF (2015) The potential of using pulsed electric field (PEF) technology as the cell disruption method to extract lipid from microalgae for biodiesel production. Int J Renew Energy Res-IJRER 5:598–621

Ju ZY, Howard LR (2003) Effects of solvent and temperature on pressurized liquid extraction of anthocyanins and total phenolics from dried red grape skin. J Agric Food Chem 51(18):5207–5213

Katsinas N, Bento da Silva A, Enríquez-de-Salamanca A, Fernández N, Bronze MR, Rodríguez-Rojo S (2021) Pressurized liquid extraction optimization from supercritical defatted olive pomace: a green and selective phenolic extraction process. ACS Sustain Chem Eng 9(16):5590–5602

Khoddami A, Wilkes MA, Roberts TH (2013) Techniques for analysis of plant phenolic compounds. Molecules 18(2):2328–2375

Khomdram SD, Singh PK (2011) Polyphenolic compounds and free radical scavenging activity in eight lamiaceae herbs of manipur. Not Sci Biol 3(2):108–113

Kongkiatpaiboon S, Gritsanapan W (2013) Optimized extraction for high yield of insecticidal didehydrostemofoline alkaloid in stemona collinsiae root extracts. Ind Crops Prod 41:371–374

Kumar S, Pandey AK (2013) Chemistry and biological activities of flavonoids: an overview. Sci World J 2013:1–16

Li D, Zhang Y, Liu Y, Sun R, Xia M (2015) Purified anthocyanin supplementation reduces dyslipidemia, enhances antioxidant capacity, and prevents insulin resistance in diabetic patients. J Nutr 145(4):742–748

Liberatore L, Procida G, d’Alessandro N, Cichelli A (2001) Solid-phase extraction and gas chromatographic analysis of phenolic compounds in virgin olive oil. Food Chem 73(1):119–124

Liu H, Jiao Z, Liu J, Zhang C, Zheng X, Lai S, Chen F, Yang H (2013) Optimization of supercritical fluid extraction of phenolics from date seeds and characterization of its antioxidant activity. Food Anal Methods 6(3):781–788

Liu ZW, Zeng XA, Ngadi M (2018) Enhanced extraction of phenolic compounds from onion by pulsed electric field (PEF). J Food Process Preserv 42(9):e13755

Lu Y, Shen Q, Dai Z (2011) Multiwalled carbon nanotubes as sorbent for online solid-phase extraction of resveratrol in red wines prior to fused-core C18-based ultrahigh-performance liquid chromatography− tandem mass spectrometry quantification. J Agric Food Chem 59(1):70–77

Makkar HP, Becker K (1993) Vanillin-hcl method for condensed tannins: effect of organic solvents used for extraction of tannins. J Chem Ecol 19(4):613–621

Maleki SJ, Crespo JF, Cabanillas B (2019) Anti-inflammatory effects of flavonoids. Food Chem 299:125124

Manach C, Scalbert A, Morand C, Rémésy C, Jiménez L (2004) Polyphenols: food sources and bioavailability. Am J Clin Nutr 79(5):727–747

Mansouri A, Embarek G, Kokkalou E, Kefalas P (2005) Phenolic profile and antioxidant activity of the algerian ripe date palm fruit (Phoenix dactylifera). Food Chem 89(3):411–420

Martin M, Guiochon G (2005) Effects of high pressure in liquid chromatography. J Chromatogr A 1090(1–2):16–38

Martorana M, Arcoraci T, Rizza L, Cristani M, Bonina FP, Saija A, Trombetta D, Tomaino A (2013) In vitro antioxidant and in vivo photoprotective effect of pistachio (Pistacia vera L., variety bronte) seed and skin extracts. Fitoterapia 85:41–48

Md Yusof NB, Hasan MH, Armayni UA, Ahmad MSB, Wahab IA (2013) The ferrous ion chelating assay of Pandanus extracts. Paper presented at the The Open Conference Proceedings Journal

Mencin M, Mikulic-Petkovsek M, Veberič R, Terpinc P (2021) Development and optimisation of solid-phase extraction of extractable and bound phenolic acids in spelt (Triticum spelta L.) seeds. Antioxidants (Basel, Switzerland) 10(7)

Miller NJ, Rice-Evans C, Davies MJ, Gopinathan V, Milner A (1993) A novel method for measuring antioxidant capacity and its application to monitoring the antioxidant status in premature neonates. Clin Sci 84(4):407–412

Molina-Dıaz A, Ortega-Carmona I, Pascual-Reguera M (1998) Indirect spectrophotometric determination of ascorbic acid with ferrozine by flow-injection analysis. Talanta 47(3):531–536

Mukhopadhyay S, Luthria DL, Robbins RJ (2006) Optimization of extraction process for phenolic acids from black cohosh (Cimicifuga racemosa) by pressurized liquid extraction. J Sci Food Agric 86(1):156–162

Munteanu IG, Apetrei C (2021) Analytical methods used in determining antioxidant activity: A review. Int J Mol Sci 22(7):3380

Murayama W, Kobayashi T, Kosuge Y, Yano H, Nunogaki Y, Nunogaki K (1982) A new centrifugal counter-current chromatograph and its application. J Chromatogr A 239:643–649

Niessen W (2001) Principles and lnstrumentation oi gas chromatography-mass spectrometry. In: Current Practice of Gas Chromatography-Mass Spectrometry. CRC Press

Nováková L, Vlčková H (2009) A review of current trends and advances in modern bio-analytical methods: chromatography and sample preparation. Anal Chim Acta 656(1–2):8–35

Ouahida D, Ridha OM, Eddine LS (2016) Influence of extraction method on phytochemical composition and antioxidant activity from leaves extract of algerian Phoenix dactylifera L. Int J Curr Pharm Rev Res 7(2):84–89

Oyaizu M (1986) Studies on products of browning reaction antioxidative activities of products of browning reaction prepared from glucosamine. Jpn J Nutr Diet 44(6):307–315

Pan X, Niu G, Liu H (2002) Comparison of microwave-assisted extraction and conventional extraction techniques for the extraction of tanshinones from Salvia miltiorrhiza bunge. Biochem Eng J 12(1):71–77

Paraskeva C, Papadakis V, Kanellopoulou D, Koutsoukos P, Angelopoulos K (2007) Membrane filtration of olive mill wastewater and exploitation of its fractions. Water Environ Res 79(4):421–429

Pereira DM, Valentão P, Pereira JA, Andrade PB (2009) Phenolics: from chemistry to biology. Molecular Diversity Preservation International, vol 14, pp 2202–2211

Pitt JJ (2009) Principles and applications of liquid chromatography-mass spectrometry in clinical biochemistry. Clin Biochem Rev 30(1):19–34

Puértolas E, Luengo E, Álvarez I, Raso J (2012) Improving mass transfer to soften tissues by pulsed electric fields: fundamentals and applications. Annu Rev Food Sci Technol 3:263–282

Radzali SA, Markom M, Saleh NM (2020) Co-solvent selection for supercritical fluid extraction (sfe) of phenolic compounds from Labisia pumila. Molecules 25(24):5859

Rodrigo R, Prat H, Passalacqua W, Araya J, Bächler JP (2008) Decrease in oxidative stress through supplementation of vitamins C and E is associated with a reduction in blood pressure in patients with essential hypertension. Clin Sci 114(10):625–634

Rodríguez De Luna SL, Ramírez-Garza R, Serna Saldívar SO (2020) Environmentally friendly methods for flavonoid extraction from plant material: impact of their operating conditions on yield and antioxidant properties. Sci World J 2020:1–38

Saafi EB, El Arem A, Issaoui M, Hammami M, Achour L (2009) Phenolic content and antioxidant activity of four date palm (Phoenix dactylifera L.) fruit varieties grown in Tunisia. Int J Food Sci Technol 44(11):2314–2319

Salgado P, Melin V, Contreras D, Moreno Y, Mansilla HD (2013) Fenton reaction driven by iron ligands. J Chil Chem Soc 58(4):2096–2101

Šamec D, Karalija E, Šola I, Vujčić Bok V, Salopek-Sondi B (2021) The role of polyphenols in abiotic stress response: the influence of molecular structure. Plants 10(1):118

Saleh EA, Tawfik MS, Abu-Tarboush HM (2011) Phenolic contents and antioxidant activity of various date palm (Phoenix dactylifera L.) fruits from Saudi Arabia. Food Sci Nutr 2(10):1134–1141

Santos JS, Alvarenga Brizola VR, Granato D (2017) High-throughput assay comparison and standardization for metal chelating capacity screening: A proposal and application. Food Chem 214:515–522

Santos JH, Almeida MR, Martins CI, Dias AC, Freire MG, Coutinho JA, Ventura SP (2018) Separation of phenolic compounds by centrifugal partition chromatography. Green Chem 20(8):1906–1916

Scalbert A (1992) Quantitative methods for the estimation of tannins in plant tissues. In: Plant Polyphenols. Basic Life Sciences, vol 59. Springer, Boston, MA

Schofield P, Mbugua D, Pell A (2001) Analysis of condensed tannins: A review. Anim Feed Sci Tech 91:21–40

Seidel V (2012) Initial and bulk extraction of natural products isolation. Methods Mol Biol 864:27–41

Shraim AM, Ahmed TA, Rahman MM, Hijji YM (2021) Determination of total flavonoid content by aluminum chloride assay: A critical evaluation. LWT 150:111932

Skoog DA, Holler FJ, Crouch SR (2017) Principles of instrumental analysis. Cengage learning

Solís-Oba M, Ugalde-Saldívar VM, González I, Viniegra-González G (2005) An electrochemical–spectrophotometrical study of the oxidized forms of the mediator 2, 2′-azino-bis-(3-ethylbenzothiazoline-6-sulfonic acid) produced by immobilized laccase. J Electroanal Chem 579(1):59–66

Spigno G, De Faveri D (2009) Microwave-assisted extraction of tea phenols: a phenomenological study. J Food Eng 93(2):210–217

Staško A, Brezová V, Biskupič S, Mišík V (2007) The potential pitfalls of using 1, 1-diphenyl-2-picrylhydrazyl to characterize antioxidants in mixed water solvents. Free Radical Res 41(4):379–390

Strack D, Dey P (1997) Phenolic Metabolism. Plant Biochemistry. Academic Press, San Diego, pp 387–416