Abstract

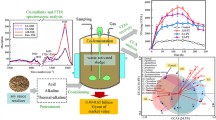

Sargassum tides on the coasts of the Mexican Caribbean have become an ecological and socioeconomic problem that requires a comprehensive solution. In this study, compositional analyses of Sargassum consortium (SC) showed 24.61% of carbohydrates, which could be used in alginate, fucoidan, and biofuel production. Also, 3.14 mg of p-Coumaric acid/g of SC was identified by high-performance liquid chromatography (HPLC). This compound is a precursor to the monolignols involved in the synthesis of lignin. Moreover, gallic and vanillic acid were found in concentrations of 2.90 and 3.37 mg of compound/g of SC. HPLC and infrared spectra analysis confirmed the presence of lignin in the SC. In order to propose potential biorefinery applications, an alginate extraction process was developed and evaluated; results indicated that alginate has lower metal content than the original biomass. A reduction in six metals was achieved, including arsenic, to below the detection limit, and the decrease of 95.4% of zinc and 75.3% of aluminum. Furthermore, the characterization of the solid waste from the alginate extraction showed an increased in glucose, xylose, and fucose proportion, when compared with the initial biomass. In addition, carbon–nitrogen maintained an optimal ratio of 20.35 to be used for biofuel production and value-added compounds, allowing the development of a biorefinery system involving zero waste from SC, which would help to reduce negative environmental and socioeconomic impacts.

Similar content being viewed by others

References

Aguirre Muñoz A (2019) El sargazo en el caribe mexicano: de la negación y el voluntarismo a la realidad. Sustentabilidad, Gac Digit del Cent Interdiscip Biodivers y Ambient 2.https://doi.org/10.1017/CBO9781107415324.004

Wang M, Hu C, Barnes BB et al (2019) The great Atlantic Sargassum belt. Science 364:83–87. https://doi.org/10.1126/science.aaw7912

Sissini MN, De Barros Barreto MBB, Szećhy MTM et al (2017) The floating Sargassum (Phaeophyceae) of the South Atlantic Ocean - Likely scenarios. Phycologia 56:321–328. https://doi.org/10.2216/16-92.1

van Tussenbroek BI, Hernández Arana HA, Rodríguez-Martínez RE et al (2017) Severe impacts of brown tides caused by Sargassum spp. on near-shore Caribbean seagrass communities. Mar Pollut Bull 122:272–281. https://doi.org/10.1016/j.marpolbul.2017.06.057

Rodríguez-Martínez RE, Medina-Valmaseda AE, Blanchon P et al (2019) Faunal mortality associated with massive beaching and decomposition of pelagic Sargassum. Mar Pollut Bull 146:201–205. https://doi.org/10.1016/j.marpolbul.2019.06.015

Maurer AS, De Neef E, Stapleton S (2015) Sargassum accumulation may spell trouble for nesting sea turtles. Front Ecol Environ 13:394–395. https://doi.org/10.1890/1540-9295-13.7.394

Chávez V, Uribe-Martínez A, Cuevas E et al (2020) Massive influx of pelagic Sargassum spp. On the coasts of the Mexican Caribbean 2014–2020: Challenges and opportunities. Water (Switzerland) 12:1–24. https://doi.org/10.3390/w12102908

Coração ACDS, Santos FS Dos, Duarte JAD et al (2020) What do we know about the utilization of the Sargassum species as biosorbents of trace metals in Brazil? J Environ Chem Eng 8.https://doi.org/10.1016/j.jece.2020.103941

Milledge JJ, Maneein S, Arribas E, Bartlett D (2020) Sargassum inundations in Turks and Caicos : methane potential and proximate, ultimate, lipid, amino acid, metal and metalloid analyses. Energies 13:1523

Supattra M, Milledge J, Nielsen B, Harvey P (2018) A review of seaweed pre-treatment methods for enhanced biofuel production by anaerobic digestion or fermentation. Fermentation 4.https://doi.org/10.3390/fermentation4040100

Vázquez-Delfín E, Freile-Pelegrín Y, Salazar-Garibay A, et al (2021) Species composition and chemical characterization of Sargassum influx at six different locations along the Mexican Caribbean coast. Sci Total Environ 795.https://doi.org/10.1016/j.scitotenv.2021.148852

Thompson TM, Young BR, Baroutian S (2020) Pelagic Sargassum for energy and fertiliser production in the Caribbean: a case study on Barbados. Renew Sustain Energy Rev 118:109564. https://doi.org/10.1016/j.rser.2019.109564

Saldarriaga-Hernandez S, Hernandez-Vargas G, Iqbal HMN et al (2020) Bioremediation potential of Sargassum sp. biomass to tackle pollution in coastal ecosystems: circular economy approach. Sci Total Environ 715. https://doi.org/10.1016/j.scitotenv.2020.136978

Rodríguez-Martínez RE, Roy PD, Torrescano-Valle N et al (2020) Element concentrations in pelagic Sargassum along the Mexican Caribbean coast in 2018–2019. PeerJ 2020:1–19. https://doi.org/10.7717/peerj.8667

Alzate-Gaviria L, Domínguez-Maldonado J, Chablé-Villacís R et al (2021) Presence of polyphenols complex aromatic “lignin” in Sargassum spp. from Mexican Caribbean. J Mar Sci Eng 9:1–10. https://doi.org/10.3390/jmse9010006

Cesário MT, da Fonseca MMR, Marques MM, de Almeida MCMD (2018) Marine algal carbohydrates as carbon sources for the production of biochemicals and biomaterials. Biotechnol Adv 36:798–817. https://doi.org/10.1016/j.biotechadv.2018.02.006

Aparicio E, Rodríguez-Jasso RM, Lara A et al (2020) Biofuels production of third generation biorefinery from macroalgal biomass in the Mexican context: An overview. Sustainable Seaweed Technologies 393–446

Dickson R, Ryu JH, Liu J (2020) Optimal design of macroalgae-based integrated biorefinery: economic and environmental perspective. Comput Aided Chem Eng 48:793–798. https://doi.org/10.1016/B978-0-12-823377-1.50133-6

del Río PG, Gullón B, Pérez-Pérez A, et al (2021) Microwave hydrothermal processing of the invasive macroalgae Sargassum muticum within a green biorefinery scheme. Bioresour Technol 340.https://doi.org/10.1016/j.biortech.2021.125733

Kostas ET, Adams JMM, Ruiz HA et al (2021) Macroalgal biorefinery concepts for the circular bioeconomy: a review on biotechnological developments and future perspectives. Renew Sustain Energy Rev 151:111553. https://doi.org/10.1016/j.rser.2021.111553

Balboa EM, Moure A, Domínguez H (2015) Valorization of Sargassum muticum biomass according to the biorefinery concept. Mar Drugs 13:3745–3760

Florez-Fernandez N, Illera M, Sanchez M et al (2021) Integrated valorization of Sargassum muticum in biorefineries. Chem Eng J 404:125635

Kostas ET, White DA, Cook DJ (2017) Development of a bio-refinery process for the production of speciality chemical, biofuel and bioactive compounds from Laminaria digitata. Algal Res 28:211–219

Amador-Castro F, García-Cayuela T, Alper HS et al (2021) Valorization of pelagic sargassum biomass into sustainable applications: current trends and challenges. J Environ Manage 283:112013

El Atouani S, Bentiss F, Reani A et al (2016) The invasive brown seaweed Sargassum muticum as new resource for alginate in Morocco: Spectroscopic and rheological characterization. Phycol Res 64:185–193. https://doi.org/10.1111/pre.12135

Ardalan Y, Jazini M, Karimi K (2018) Sargassum angustifolium brown macroalga as a high potential substrate for alginate and ethanol production with minimal nutrient requirement. Algal Res:29–36.https://doi.org/10.1016/j.algal.2018.10.010

Rosado-Espinosa LA, Freile-Pelegrín Y, Hernández-Nuñez E, Robledo D (2020) A comparative study of Sargassum species from the Yucatan peninsula coast: morphological and chemical characterisation. Phycologia:1–11.https://doi.org/10.1080/00318884.2020.1738194

Milledge JJ, Nielsen BV, Harvey PJ (2018) The inhibition of anaerobic digestion by model phenolic compounds representative of those from Sargassum muticum. J Appl Phycol 31:779–786. https://doi.org/10.1007/s10811-018-1512-4

Hernández-Carmona G, Rodríguez-Montesinos Y, Arvizu-Higuera D et al (2012) Technological Advance for Alginate Production in Mexico. Ing Investig y Tecnol XIII:155–168

Kumar S, Sahoo D (2017) A comprehensive analysis of alginate content and biochemical composition of leftover pulp from brown seaweed Sargassum wightii. Algal Res 23:233–239

Mazumder A, Holdt SL, De Francisci D et al (2016) Extraction of alginate from Sargassum muticum: process optimization and study of its functional activities. J Appl Phycol 28:3625–3634. https://doi.org/10.1007/s10811-016-0872-x

Rhein-Knudsen N, Ale MT, Ajalloueian F, Meyer AS (2017) Characterization of alginates from Ghanaian brown seaweeds: Sargassum spp. and Padina spp. Food Hydrocoll 71:236–244

Mohammed A, Bissoon R, Bajnath E et al (2018) Multistage extraction and purification of waste Sargassum natans to produce sodium alginate: an optimization approach. Carbohydr Polym 198:109–118

Flórez-Fernández N, Domínguez H, Torres MD (2019) Advances in the biorefinery of Sargassum muticum: valorisation of the alginate fractions. Ind Crops Prod 138:111483

Sluiter A, Hames B, Ruiz R et al (2008) Determination of ash in biomass. NREL/TP-510–42622. Lab Anal Proced 36:302–305

Sluiter A, Hames B, Ruiz R et al (2008) Determination of structural carbohydrates and lignin in biomass: laboratory analytical procedure (LAP); Issue Date: April 2008; Revision Date: July 2011 (Version 07–08–2011) - 42618.pdf. Tech Rep NREL/ TP -510 -42618 1–15

Machu L, Misurcova L, Ambrozova JV et al (2015) Phenolic content and antioxidant capacity in algal food products. Molecules 20:1118–1133. https://doi.org/10.3390/molecules20011118

Reyes-Rivera J, Canché-Escamilla G, Soto-Hernández M, Terrazas T (2015) Wood chemical composition in species of Cactaceae the relationship between lignification and stem morphology. PLoS One 10:1–17. https://doi.org/10.1371/journal.pone.0123919

Davis D, Simister R, Campbell S et al (2021) Biomass composition of the golden tide pelagic seaweeds Sargassum fluitans and S. natans (morphotypes I and VIII) to inform valorisation pathways. Sci Total Environ 762:143134

Aparicio E, Rodríguez-Jasso RM, Pinales-Márquez CD et al (2021) High-pressure technology for Sargassum spp biomass pretreatment and fractionation in the third generation of bioethanol production. Bioresour Technol 329:1–10. https://doi.org/10.1016/j.biortech.2021.124935

Paraguay-Delgado F, Carreño-Gallardo C, Estrada-Guel I et al (2020) Pelagic Sargassum spp. capture CO2 and produce calcite. Environ Sci Pollut Res:1–7. https://doi.org/10.1007/s11356-020-08969-w

Thompson TM, Young BR, Baroutian S (2020) Efficiency of hydrothermal pretreatment on the anaerobic digestion of pelagic Sargassum for biogas and fertiliser recovery. Fuel 279:118527. https://doi.org/10.1016/j.fuel.2020.118527

Oliveira JV, Alves MM, Costa JC (2015) Optimization of biogas production from Sargassum sp. using a design of experiments to assess the co-digestion with glycerol and waste frying oil. Bioresour Technol 175:480–485. https://doi.org/10.1016/j.biortech.2014.10.121

López-Sosa LB, Alvarado-Flores JJ, Corral-Huacuz JC et al (2020) A prospective study of the exploitation of pelagic Sargassum spp. as a solid biofuel energy source. Appl Sci 10:1–17. https://doi.org/10.3390/app10238706

Tapia-Tussell R, Avila-Arias J, Maldonado JD et al (2018) Biological pretreatment of Mexican Caribbean macroalgae consortiums using Bm-2 strain (Trametes hirsuta) and its enzymatic broth to improve biomethane potential. Energies 11.https://doi.org/10.3390/en11030494

Martone PT, Estevez JM, Lu F et al (2009) Discovery of lignin in seaweed reveals convergent evolution of cell-wall architecture. Curr Biol 19:169–175. https://doi.org/10.1016/j.cub.2008.12.031

Antúnez-Argüelles E, Herrera-Bulnes M, Torres-Ariño A et al (2020) Enzymatic-assisted polymerization of the lignin obtained from a macroalgae consortium, using an extracellular laccase-like enzyme (Tg-laccase) from Tetraselmis gracilis. J Environ Sci Health A Tox Hazard Subst Environ Eng 55:739–747. https://doi.org/10.1080/10934529.2020.1738171

Chávez-Sifontes M, Domine ME (2013) Lignin, structure and applications: Depolymerization methods for obtaining aromatic derivatives of industrial interest. Av. en Ciencias e Ing 4:15–46

Alves T, Silva L, Dário H, Zamora Z (2018) Effect of steam explosion pretreatment catalysed by organic acid and alkali on chemical and structural properties and enzymatic hydrolysis of sugarcane bagasse. Waste Biomass Valorization 9:2191–2201. https://doi.org/10.1007/s12649-017-9989-7

Chablé-Villacis R, Olguin-Maciel E, Toledano-Thompson T et al (2021) Enzymatic hydrolysis assisted with ligninocellulolytic enzymes from Trametes hirsuta produced by pineapple leaf waste bioconversion in solid-state fermentation. Biomass Convers Biorefinery 1–12. https://doi.org/10.1007/s13399-021-01851-w

Chandra Rajak R, Banerjee R (2015) Enzymatic delignification: an attempt for lignin degradation from lignocellulosic feedstock. RSC Adv 5:75281–75291. https://doi.org/10.1039/c5ra09667g

Thompson TM, Young BR, Baroutian S (2019) Advances in the pretreatment of brown macroalgae for biogas production. Fuel Process Technol 195:106151. https://doi.org/10.1016/j.fuproc.2019.106151

Acknowledgements

The authors wish to thank Jose Martin Baas-López, M.Sc. for technical assistance.

Funding

This research was financed by the Sectorial Fund for Research and Development in Naval Sciences of the National Council of Science and Technology (CONACYT), and the Navy Minister (SEMAR) as project No. 305292 and CONACYT Infrastructure Project No. 253986, and through the master’s scholarship number 753155.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azcorra-May, K.J., Olguin-Maciel, E., Domínguez-Maldonado, J. et al. Sargassum biorefineries: potential opportunities towards shifting from wastes to products. Biomass Conv. Bioref. 14, 1837–1845 (2024). https://doi.org/10.1007/s13399-022-02407-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02407-2