Abstract

This study proposes the valorization of sunflower by-product (SbP) using subcritical water treatment. For this purpose, a response surface methodology in a 3 × 3 Box–Behnken design was employed to study the effect of temperature (100–150 °C), extraction time (5–25 min), and solvent-to-feed ratio (10–20 g bidistilled water/g SbP) on the water-soluble compounds. The highest amount of glucose (5.7-mg/g raw material) and xylose (13.5-mg/g raw material) was obtained at 150 °C and solvent-to-feed ratio of 15 after 25 min of extraction. The highest amount of protein (133.5-mg/g raw material) was obtained at 150 °C and solvent-to-feed ratio of 20 after 15 min of extraction. The selected temperature conditions did not promote the formation of final degradation products such as furfural and 5-hydroxymethylfurfural (HMF). The extracts obtained in this study showed simultaneous recovery of free monomeric sugars that could be used for bioenergy or biochemical, proteins that could be used for food and pharmaceutical industries and phenolic compounds that could be used for food and nutraceutical applications.

Similar content being viewed by others

1 Introduction

Sunflower cake/meal is the by-product of the edible oil industry. Currently, sunflower is produced in large quantities in the world (53.5 million tons) [1]. In this sense, large quantities of waste materials are generated from the sunflower oil extraction process. In 2019, the Ukraine and Russian federation were the main producers of sunflower by-product (SbP) (6.7 and 5.7 million tons, respectively) followed by the European Union (EU-27) with 4.7 million tons [2]. Despite being produced in large quantities, this agro-industrial residue has very limited reuse.

After oil extraction, the residue of sunflower contains a high amount of protein (> 27%) with 4.37% of essential amino acids [3]. The residue resulting from the oil extraction process also contains lignin (20.4–26.62%), cellulose (32.93–39.1%), hemicelluloses (18.4–30.9%) minerals (151.35 mg/kg), and polyphenols (2–5%), mainly chlorogenic acid (CGA) (which corresponds to more than 70% of all phenolic present in the SbP) [4,5,6,7].

Despite the high nutritional value and its potential uses as gelling, foaming, emulsifying, and polymer in chemical, pharmacological, and food industries [4], the SbP biomass is almost exclusively employed for animal feeding [5]. This is mainly because the use of the SbP in industrial processes has been scarcely reported in the current literature. Therefore, more studies are needed to promote the reuse of the SbP as a renewable and cheap resource in order to add value to the sunflower production chain, incorporating the biorefinery context to this biomass.

The use of subcritical water has proven in recent years to be an environmentally friendly green and rapid method to obtain water-soluble compounds. This method can be used for the extraction of bioactive compounds or as a substitute to other methods that use acidic, alkaline, and enzymatic media for the hydrolysis of macromolecules (proteins into peptides and amino acids and polysaccharides to fermentable sugars) [8,9,10]. To achieve the subcritical state, water is heated at temperatures between its boiling point (100 °C) and its critical temperature (374 °C) and pressure is applied in order to ensure that the water will remain in a liquid state throughout the process [11, 12]. The use of this technology has been widely used to extract sugars and phenolic and antioxidants compounds from several by-products such as asparagus [13], peach palm [14], coffee residue [15], and rice straw [16].

For the best of our knowledge, only studies involving the treatment of fresh sunflower using subcritical solvent was reported in the literature. For instance, Sutanto et al. [17] studied the production of fatty acid methyl esters (FAMEs) (yield of 88–93%) from kernels with a subcritical solvent mixture of methanol and acetic acid (200–250 °C). Ravber et al. [18] evaluated the subcritical water extraction from sunflower seeds (60–160 °C) for the recovery of oil and water-soluble compounds. In this study, the highest amount of oil (44%) was obtained at 130 °C at a solvent/solid ratio of 20 and an extraction time of 30 min. The effect of subcritical water in the hydrothermal degradation of some compounds present in SbP was also evaluated by the same group [19]. In this study, the authors observed that with temperatures higher than 220 °C, no more carbohydrates were found in the extract (only inhibitors) and that the content of amino acid and amine did not change over the reaction time at temperature of 130 °C.

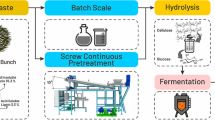

Therefore, the aim of the present work was the valorization of the SbP using subcritical water to obtain fermentable sugars (glucose and xylose), proteins, amino acids, and CGA. The liquid solution was also analyzed in terms of total phenolic content and antioxidant capacity. The solid co-product obtained after the subcritical water treatment was analyzed in terms of protein content and amino acid profile.

2 Materials and methods

2.1 Raw material preparation and characterization

The SbP (a mixture of kernel and shells) was supplied by a local agricultural cooperative located in Olmedo, Spain, in February 2020. The SbP was milled into small particles (particle size of 0.42 ± 0.02 mm) in a commercial mill (Cueffer, B07DVN18PS, Taiwan, China). After the milling process, the SbP was characterized in terms of moisture (NREL/TP-510–42,621), ash (NREL/TP-510–42,622), extractives (NREL/TP-510–42,619), protein (NREL/TP-510–42,625; using a conversion factor of 6.25), soluble lignin (NREL/TP-510–42,618), and insoluble lignin (NREL/TP-510–42,618) by using methodologies recommended by the National Renewable Energy Laboratory described in the technical reports [20,21,22,23,24].

2.2 Sunflower by-product extraction using subcritical water

The extraction was carried out in a 145 mL stainless steel reactor (with a length of 77 mm, an internal diameter of 49 mm, and a wall thickness of 11 mm). The extractor was heated by an electric system, the temperature was measured with a thermocouple and controlled by a PID controller, and the pressure inside the reactor was measured by a manometer (0–25 bar). A schematic diagram of the equipment is shown in Fig. 1.

For each extraction assay, an amount of SbP (accuracy of 0.001 g) was loaded in the reactor, and subsequently, 100 g of the bidistilled water was added to obtain an appropriate solvent-to-feed solid ratio (S/F; g bidistilled water/g SbP). The studied values of S/F were 10 (100-g bidistilled water/10 g SbP), 15 (100 g bidistilled water/6.66 g SbP), and 20 (100-g bidistilled water/5 g SbP), which were defined by preliminary experiments. Afterward, the system was closed and heated up to the desired temperature. The suspension was stirred continuously at a constant rotational speed of 300 rpm during each process to increase mass and heat transfer and prevent local overheat on the inner walls of the extractor. The experimental temperatures were 100, 125, and 150 °C. The pressure was the water saturation pressure at the reaction temperature (0.10 MPa for 100 °C, 0.23 MPa for 125 °C, and 0.47 MPa for 150 °C). Extraction times were 5, 15, and 25 min. The extraction temperature and time were chosen according to Ravber et al. [19] in order to avoid the thermal degradation of sugars and proteins. The highest severity factor used in this work was log R0 equal to 2.8, calculated by Eq. (1), that is rather below the value of 3.7 to avoid the production of inhibitors such as furfural and 5-HMF (hydroxymethylfurfural) according to previous results of our research group [25]. At the end of the experiments, the reactor was immediately cooled down in an ice bath and the suspension was filtered under vacuum. The liquid phase was filtered through a 0.22-μm cellulose acetate and stored at 4 °C for further analysis and the remaining solid residue from each assay of extraction was collected and dried in an oven at 105 °C until constant weight for its characterization.

being t time in minutes, T temperature in °C, 100 °C a reference temperature, and 14.75 an arbitrary constant related with activation energy.

2.3 Analyses of extracts

2.3.1 pH determination

The pH of the extracts was measured after each experimental run using a digital pH meter (Jenway Digital Meter, 3505, England).

2.3.2 Quantification of sugars, organic acids, and inhibitors by high-performance liquid chromatography (HPLC)

The extracts were analyzed using a Water Breeze 1525 HPLC system (Waters, Milford, USA) with an integrated column heater and 717 plus autosampler according to the method described by Adamovic et al. [26]. The separation was carried out on a Shodex SH-1011 column (SH1011, 7 μm, 8 mm × 300 mm, Waters) using a mobile phase of water acidified with sulfuric acid (0.01 N). The temperature, flow rate, and injection volume were 50 °C, 0.8 mL/min, and 25 µL, respectively. The identification of the sugars and acids was performed by comparison with the standards through retention time using Waters RI Detector 2414. The identification of the inhibitors was performed by comparison with the standards through retention time, at 254 nm using a Waters UV–Vis detector. The quantification was performed using an external calibration curve of the analytical standards. The calibration curves of the glucose (R2 = 0.9999), xylose (R2 = 1), and arabinose (R2 = 0.9999) were obtained in the range of 14–1053 μg/mL and the calibration curves of the acetic (R2 = 0.9999) and formic (R2 = 0.9999) acids were obtained in the range of 14–835 μg/mL. The calibration curves of the 5-HMF (R2 = 1) and furfural (R2 = 0.9999) were obtained in the range of 22–427 μg/mL. Sugars were expressed as mg of sugar per g of SbP.

2.3.3 Quantification of total and free amino acids by HPLC

Total and free amino acids were quantified by HPLC with a variable wavelength UV detector (Agilent Technologies 1200 Series, Germany) in the extracts obtained at 150 °C, 15 min, and S/F of 20. The total and free amino acids were separated in a Zorbax Eclipse AAA C18 column (4.6 mm × 150 mm, i.d., 3.5 μm) at 40 °C using an injection volume of 36 µL and a mobile phase of buffer NaH2PO4.H2O (pH = 7.8) (A) and acetonitrile:methanol:water (45:45:10) (B) in a gradient method described by Náthia-Neves and Alonso [3]. For the total amino acid quantification, the extract (approximately 30 mg) was hydrolyzed in a microwave system following the protocol described by Náthia-Neves and Alonso [3]. For the free amino acid quantification, the extract was filtered through a microfilter (0.22 μm) into a glass vial (2 mL) and direct analyzed in the same HPLC system (without microwave pretreatment). The quantification of each amino acid was performed from external calibration curves of the standards purchased from Sigma–Aldrich. The amino acid profile was expressed as mg of amino acid per g of SbP.

2.3.4 Quantification of CGA by HPLC

CGA content in the extracts was quantified by an HPLC–PDA (Waters, Alliance E2695, Milford, USA) system. The separation of the CGA was performed in a C18 column according to the method described by Meinhart et al. [27]. The quantification of the CGA was performed from the external calibration curve of the analytical standard purchased from Sigma–Aldrich and the CGA recovery was expressed as mg of CGA per g of SbP.

2.3.5 Total phenolic compounds (TPC) and antioxidant capacity

TPC was analyzed using the protocol reported by Singleton et al. [28]. The extracts were diluted in bidistilled water. The extract (40 μL), water (3 mL), and Folin–Ciocalteu (200 μL) reagent were mixed and incubated for 3 min at room temperature. Then, saturated sodium carbonate (600 μL) was added, and the mixture was incubated for 30 min at 40 °C. The absorbance was recorded at 765 nm and the quantification of TPC was performed from the external calibration curve of the analytical gallic acid (53 to 852 μg/mL) standard purchased from Sigma–Aldrich. TPC content was expressed as mg gallic acid equivalent (GAE) per g of SbP.

The antioxidant capacity was analyzed by the oxygen radical absorbance capacity method (ORAC). A total of 10-mM potassium phosphate buffer (PBS) at pH 7.4 was used as blank and the Trolox (12.5–200 μM) solution was used as a standard. For each analysis, 25 μL of the PBS, 25 μL of the standard dissolution (12.5, 25, 50, 100, and 200 μM), 25 μL of the extract, and 150 μL of fluorescein (100 nM) were inserted into wells of an opaque fluorescent plate and incubated for 30 min at 37 °C. Then, 25 μL of AAPH (2,2′-azobis(2-amidino-propane) dihydrochloride) solution (240 mM) was added. The fluorescence decrease (excitation wavelength was set at 485 nm; emission wavelength at 520 nm) was recorded for 130 min using a FLUOstar OPTIMA (BMG Labtech, Offenburg, Germany) equipment at 37 °C. The antioxidant capacity was expressed as μmol of Trolox equivalent (TE) per g of SbP.

2.4 Analyses of solid residue

2.4.1 Determination of the solid amount

After the subcritical water treatment, the suspension was filtered, and the remaining solid residue was transferred to a porcelain crucible and dried in an oven at 105 °C until constant weight. The difference between the initial amount of SbP (on a dry basis) and the final mass remaining in the reactor (on a dry basis) after each experimental run was used to calculate the amount of solid residue.

2.4.2 Protein and total amino acids profile by HPLC

Protein content was determined following the method proposed by NREL (NREL/TP-510–42,625; using a conversion factor of 6.25). Total amino acids were quantified both in the raw material and in the residual solid after subcritical water treatment. For this purpose, the samples were hydrolyzed in a microwave with acid (6 N HCl) and an inert atmosphere. The sample treatment and the separation of the amino acid by HPLC were carried out following the same protocol described in Section 2.3.3.

2.5 Experimental design and optimization

Response surface methodology (RSM) was applied to evaluate the effects of extraction parameters and optimize the process conditions. The Box–Behnken experimental design with three numeric factors on three levels was used. In the experimental design, the temperature (x1), extraction time (x2), and S/F (x3) were selected as independent variables (Table 1). Fifteen randomized runs with three replicates at the central point were performed. The response variables were fitted to the second-order polynomial model (Eq. 2). The experimental design was evaluated using Minitab 16® software (Minitab Inc., State College, PA, USA). The results were statistically tested by analysis of variance (ANOVA) with the significance levels of 5%.

where Y represents the response variable, Xi and Xj are the independent variables affecting the response, and β0, βi, βii, and βij are the regression coefficients for intercept, linear, quadratic, and interaction terms, respectively.

3 Results and discussion

3.1 Characterization of the raw material

Table 2 shows the SbP characterization. The moisture, ash, and protein content were similar to values reported by Ramachandran et al. [29] that found 9% moisture, 6.6% ash, and 34% protein. Lipid content and total extractives soluble in water were similar to those reported by Geneau-Sbartaï et al. [30] (2% of lipids and 22.8% of water-soluble components). The values of lignin (insoluble lignin + soluble lignin) are in agreement with those found in literature, which range from 8 to 20% [7, 30, 31]. As expected, characterization analysis establishes that SbP is a promising candidate for protein-rich extract production and for the generation of simple sugars.

3.2 Influence of process variables on sugars and protein recovery

The Box–Behnken experimental design with three replicates at the center point was used to investigate the effect of temperature, time, and S/F on the glucose, xylose, protein, TPC, CGA, and antioxidant capacity of the obtained extracts. The experimental results are shown in Table 3. Results of ANOVA for the effects of variables on the glucose, xylose, and protein are shown in Table 4 (that considers only the significant variables at 5%), with the corresponding coefficients of multiple determinations (R2) and adjusted determination coefficients (adj R2). The regression models were highly significant with satisfactory values of determination coefficients (R2 = 0.939–0.963) and adjusted determination coefficients (adj R2 = 0.915–0.949) (Table 4). These results show that the polynomial regression model can be used to navigate the design space for glucose, xylose, and protein responses.

The results in Table 4 indicated that the linear coefficients of extraction temperature and extraction time were significant on the extraction of glucose, xylose, and protein. In addition, quadratic terms of extraction temperature and the interaction between temperature and time were also significant (P < 0.05) on these responses. The three-dimensional response surface and two-dimensional contour plot for glucose, xylose, and protein are presented in Fig. 2. The second-order polynomial equations for glucose (mg/g SbP), xylose (mg/g SbP), and protein (mg/g SbP) extraction yields are shown in Eqs. (3), (4) and (5), respectively.

Three-dimensional response surface and two-dimensional contour plot. a Three-dimensional response surface for glucose; b two-dimensional contour plot for glucose; c three-dimensional response surface for xylose; d two-dimensional contour plot for xylose; e three-dimensional response surface for protein; f two-dimensional contour plot for protein

The glucose extraction yield ranged from 2.1 to 5.7 mg/g SbP and the xylose content ranged from 5.3 to 13.9 mg/g SbP for the studied combinations. Traces of arabinose were also identified in the extracts (ranging from 0.1–0.9 mg/g SbP). To the best of our knowledge, there are no studies in the literature reporting the obtention and quantification of sugars from SbP using subcritical water. Ravber et al. [18] reported the extraction of oil and water-soluble phase from fresh sunflower seeds with subcritical water. However, these authors did not quantify the sugar content present in the extracts. Alenezi, Leeke, Santos, and Khan [32] also studied the extraction of sunflower oil using subcritical water without analyzing the sugar content.

Temperature showed the strongest impact on total sugars recovery. The linear, quadratic, and the interaction between temperature and time effects had the strongest influence on total sugars extraction. As shown in Fig. 2, the increase in temperature with the increase in extraction time had a positive effect on the recovery of xylose and glucose. These results prove that the selected temperature conditions did not favor the formation of final degradation products such as furfural and 5-HMF that can occur at temperatures above 150 °C [33]. The pH of the extract ranged from 5.5 to 6.0. As shown in Fig. 3, the pH has a slight decrease as the temperature rises from 100 to 150 °C, which indicates the presence of acidic materials. In order to verify this hypothesis, an HPLC analysis was carried out, which revealed the presence of traces of organic formic and acetic acids in extracts obtained at 150 °C (less than 0.2%). According to literature, the SbP presents a low content of free monomers, 11% glucose, 3.5% xylose, 1.47% arabinose, 1.25% rhamnose, 1.13% mannose, and 1.23% galactose [34]. Glucose is mostly originated from cellulose hydrolysis under temperature between 200 and 300 °C [35]. Thus, the recovery of glucose could be improved by increasing the temperature. However, it is worth mentioning that this rise in temperature may lead to the formation of degradation products, limiting the use of the obtained extract in fermentation processes [36]. The content of glucose and xylose in the extracts of SbP are comparable to those observed in extracts of coffee industry residues (glucose = 3.3 mg/g coffee powder and xylose = 9.8 mg/g defatted coffee cake, obtained at 175 °C) [15] and in the extracts of brewer’s spent grains (glucose = 1.8 mg/g grain and xylose = 9.0 mg/ g grain, obtained at 160 °C) [37].

The protein content in the obtained extracts ranged from 33.1 to 133.5 mg/g SbP depending on operational conditions. The highest recovery of protein (133.5 mg/g SbP) was obtained at 150 °C and 15 min using S/F of 20 (Run order 3). The amount of protein recovered at 150 °C was almost twice the amount recovered at 125 °C, indicating the positive effect of increasing temperature in the recovery of these compounds. The results could be due to the higher solubility of proteins at high temperatures. At 150 °C, the dielectric constant of the subcritical water is approximately 43.96, and at 100 °C, it is approximately 55.43, which seems to decrease the ability of the medium to extract the protein phase. On the other hand, higher temperatures would result in more protein structure rupture, which is associated with the formation of amino acids and peptides. The soluble products presented a toasty aroma when the temperature increased. The interactive effect of temperature and extraction time on protein recovery is shown in Fig. 2e and f. The amount of protein in the sunflower raw material was almost 32% (Table 2), and the extract obtained at 150 °C and 15 min using S/F of 20 presented 43% of the protein in the soluble product. This result is comparable to the 59.3% protein yield obtained by Lu et al. [38] when studying the protein extraction from the HPSI using enzyme-assisted subcritical water extraction (120 °C). Although the process studied has provided a high yield of proteins, a scale-up and an economic analysis are necessary to determine the economic and technical viability of the developed process on an industrial scale.

The positive effect of temperature on the total protein content in the extracts obtained from deoiled rice bran by subcritical water was also reported by Sereewatthanawut et al. [39]. In this study, the protein content extracted ranged from ~ 48 mg/g rice bran (100 °C and 30 min) to 219 mg/g rice bran (200 °C and 30 min). The yields of protein extraction from extruded soybean flakes and non-extruded soybean flakes using subcritical water showed different behaviors. For the extruded soybean flakes, the amount of protein extracted increased with increasing temperature and the solid-to-liquid ratio decreased, while using non-extruded soybean flakes, higher protein yields were observed at low temperatures and low solid-to-liquid ratio [40]. The protein content in the extracts obtained from extruded soybean flakes ranged from 266 mg/g extruded soybeans (66 °C and 30 min) to 731 mg/g extruded soybeans (234 °C and 30 min), and the protein content extracted from soybean flakes ranged from 308 mg/g soybeans flakes (100 °C and 20 min) to 719 mg/g soybeans flakes (100 °C and 40 min) [40].

To verify the presence of amino acids in the extract obtained at 150 °C and 15 min using S/F of 20 (Run 3), the amino acid profile was analyzed by HPLC, and the results are shown in Table 5. It can be observed that the subcritical water treatment allowed to obtain an extract rich in amino acids (280 mg of total amino acids per gram of extract). The total yield of amino acids was 98.5 ± 1.1 mg/g SbP. This result was higher than the total amount of amino acids and amines found by Ravber et al. [19] (150 mg/g extract) in the water-soluble fraction of sunflower seeds obtained at 160 °C and 10 min. To the best of our knowledge, this is the first study to characterize the amino acid profile in extracts obtained from SbP using subcritical water. It is worth highlighting the presence of essential amino acids in the extracts, such as isoleucine (10.4 ± 0.4 mg/g extract), leucine (16 ± 1 mg/g extract), lysine (9 ± 1 mg/g extract), methionine (7 ± 1 mg/g extract), phenylalanine (12.2 ± 0.4 mg/g extract), threonine (12 ± 1 mg/g extract), histidine (9 ± 1 mg/g extract), and valine (10 ± 1 mg/g extract). The extract was also analyzed for free amino acid content. The free amino acids found were aspartate, glutamate, glycine, alanine, phenylalanine, and leucine. The free aspartate content found in the extract was 1.9 ± 0.1 mg/g extract, and the free glutamate, glycine, alanine, phenylalanine, and leucine content found in the extract was 0.6 ± 0.01 1 mg/g extract. These free amino acids serve as nutrients for yeasts and bacteria during alcoholic and malolactic fermentation.

3.3 Influence of process variables on CGA, TPC, and antioxidant capacity

SbP contains a wide range of compounds, such as phenolic (mainly composed of CGA), which have been shown antioxidant capacity. Thus, this section is focused to analyze CGA, TPC, and the antioxidant capacity of the obtained water-soluble products. The results of ANOVA for the effects of variables on CGA, TPC, and antioxidant capacity are shown in Table S.1 and Fig. S.1. According to ANOVA, CGA and TPC can be described by a linear model, following Eqs. (6) and (7), respectively. The value of the determination coefficient for CGA was R2 = 0.917 (Table S.1) and the adjusted determination coefficient for CGA was adj R2 = 0.903 (Table S.1). The values of the determination coefficient for TPC was R2 = 0.845 (Table S.1) and adjusted determination coefficient for TPC was adj R2 = 0.802 (Table S.1). The effect of process variables did not show any statistical difference in the antioxidant capacity of the obtained extracts determined by ORAC (Fig. S.1).

CGA content in SbP is around 1.4% w/w. Besides this compound is preferably extracted with alcohol or hydroalcoholic mixtures [3], CGA was quantified in the extracts obtained by subcritical water. The content of CGA in the aqueous extracts ranged from 2.2 to 8.9 mg/g SbP on a dry basis, diminishing with higher temperatures and longer times (Table 3). In a previous study, the negative effect of temperature on the recovery of this compound using microwave-assisted extraction and ethanol 70% as solvent was also observed [3]. Similar trends were observed during the extraction of CGA from potato and tobacco waste using subcritical water [9, 41]. According to Singh and Saldaña [41], the content of CGA from potato waste starts to decrease at 160 °C, and its complete degradation was above 180 °C. The CGA content of the present study was similar to that found in tobacco leaves (ranged from 0.5 to 15 mg/g tobacco leaves) [9] and higher than to that found in potato waste (ranged from 0.06 to 0.15 mg/g potato waste). Increasing temperature, time, and S/F the TPC yield is slightly increased. TPC ranged from 17.2 to 26 mg GAE/g SbP on a dry basis for the different studied combinations. The obtained values of TPC in this work were higher than those registered for the extracts obtained from the SbP using microwave-assisted extraction and 70% (v/v) ethanol as extracting solvent (14 mg GAE / g of SbP) [3]. Antioxidant capacity was evaluated by ORAC assay that is considered the most effective method to evaluate the antioxidant capacity in biological samples by changing the fluorescent molecule when it suffers oxidative damage caused by a source of peroxyl radicals [42, 43]. Antioxidant capacity of the solubilized products was evaluated by ORAC and ranged from 213 to 296 μmol TE/g SbP, as it can be observed in Table 3. The determined values by ORAC assay slightly decreased with temperature up to 150 °C, and this can be associated to the degradation of antioxidant compounds with temperature. The observed antioxidant capacity is comparable to that obtained from defatted orange peel (319 μmol TE/g DOP; at 150 °C) [44] and Citrus unshiu peel (281.3 mg TE/g sample; at 160 °C) [45].

The study of extraction conditions accomplished in this work allow the simultaneous recovery of (i) free monomeric sugars that could be used for bioenergy (for example, bioethanol production) or biochemicals (such as xylitol and sorbitol), (ii) proteins that could be used (after a purification study of the extract and after a technical and economic feasibility study of the process developed) for food and pharmaceutical industries (as emulsifiers or gelling agents), and (iii) phenolic compounds that could be used for food and nutraceutical applications (after biological activity studies). Therefore, these results place this SbP as potential biomass to be studied in industrial uses.

3.4 Validation of the model

To test the suitability of the model equations, the extraction of SbP was carried out by triplicate at 140 °C, extraction time of 10 min, and S/F of 18. These conditions exhibited a predicted value of 3.29 mg/g SbP, 7.69 mg/g SbP, 75.14 mg/g SbP, 4.45 mg/g SbP, and 22.70 mg/g SbP for glucose, xylose, protein, CGA, and TPC, respectively. The trial values were found to be 3.61 ± 0.3 mg/g SbP, 6.9 ± 0.65 mg/g SbP, 70.5 ± 1.8 mg/g SbP, 4.15 ± 0.55 mg/g SbP, and 20.4 ± 1.5 mg/g SbP for glucose, xylose, protein, CGA, and TPC, respectively. Therefore, it can be concluded that the results obtained from the validated trials demonstrated adequacy to the developed models.

3.5 Solid co-product

The solid after the subcritical water treatment was quantified and analyzed. Figure 4 shows the masses of residual solids remaining in the reactor after each experiment run. An increase in temperature leads to a decrease in the amount of residual solids (Run 3, 6, 10, and 13 were performed at 150 °C) suggesting that a larger amount of SbP was solubilized into the water-soluble phase at 150 °C. This behavior was also reported in the subcritical water treatment of rice straw [16] and coffee residue [15] at high temperatures due to larger dissociation of lignocellulosic structure. In the experiments performed with rice straw, the authors observed a 50% (approximately) reduction in the residual solids content when the temperature was increased from 180 to 260 °C. For coffee residue, the authors observed a relationship between the decrease in the solids content of the residue with a 15% increase in the rate of hydrolysis when the temperature was increased from 150 to 200 °C (at 22.5 MPa). The residue obtained at 150 °C, 15 min, and S/F 20 (Run 3) was characterized in terms of protein content and amino acid profile, and the results were compared with the fresh raw material.

The content of proteins in fresh SbP was 31.8 ± 0.1%, whereas this content increased to 37.8 ± 0.1% in the residual solid recovered after the subcritical water treatment. This result indicates that there was a concentration of protein in the solid that may be associated with the extraction of sugars and phenolics in a major extent.

The use of by-products and waste of agro-industrial processing as a source for obtaining amino acids has increased in recent years, as they are abundant and cheap sources [46]. Figure 5 shows the amino acid profile of the fresh and the treated SbP. The total content of amino acids present in the fresh and the treated SbP was 210 mg/gSbP and 234 mg/gSbP, respectively. These results can be compared to those obtained from scientifically recognized sources for having a high amino acid content such as algae (ranging from 18 to 47%, wheat basis) [47] and the soybean seeds (ranging from 34 to 52%) [48, 49]. The results obtained in this study also indicate the presence of essential amino acids isoleucine, leucine, lysine, methionine, phenylalanine, threonine, histidine, and valine that play important roles in maintaining human health. The biological activity of amino acids present in by-products such as brewers’ spent grain (angiotensin-converting enzyme (ACE) inhibitory), red alga (ACE inhibitory), potato starch industry by-product (ACE inhibitory, antioxidant, lipolysis stimulating, anti-cholesterol), and olive flower by-product (antioxidant and antihypertensive) [46] has been reported in the literature as well as the biological activity of the hydrolyzate obtained from sunflower by-product using ultrasonic pretreatment (ACE inhibition) [50]. It can be observed that the subcritical water treatment increased the content of all amino acid present in the used SbP. Glutamate (47 ± 1 mg/g SbP for fresh and 50 ± 1 mg/g SbP for treated SbP) was the amino acid found in greater quantity in the samples and cysteine (3.25 ± 0.03 mg/g SbP for fresh and 3.37 ± 0.05 mg/g SbP for treated SbP) was the minor amino acid found in the samples. Thus, this residue can be applied to the preparation of products intended for human consumption. Grasso et al. [51], for example, studied the partial replacement of wheat flour by SbP in biscuits and obtained a product rich in protein, TPC, and antioxidant activity.

Amino acid profile in the sunflower by-product before and after the subcritical water treatment. ASP, aspartate; GLU, glutamate; ASN, asparagine; SER, serine; GLN, glutamine; HIS, histidine; GLY, glycine; THR, threonine; ARG, arginine; ALA, alanine; TYR, tyrosine; CYS, cysteine; VAL, valine; MET, methionine; TRP, tryptophan; PHE, phenylalanine; ILE, isoleucine; LEU, leucine; LYS, lysine; PRO, proline

4 Conclusions

The use of subcritical water showed to be a potential technique to produce fermentable sugars (glucose and xylose), protein, amino acids, chlorogenic acid, and natural antioxidants from the sunflower by-product. The applied conditions did not produce inhibitors (furfural and 5-HMF). Thus, the aqueous sunflower extracts could be used as an additive with direct application into food, cosmetics, pharmaceutical industries, or for producing bioethanol. The solid co-product obtained after the treatment showed a high content of proteins and amino acids that motivate future studies for its use in industrial applications such as food (protein supplements) and pharmaceuticals (due to the presence of essential amino acids).

Data availability

Not applicable.

References

FAO, Food Agriculture Organization of the United Nations (2019) Food outlook: biannual report on global food markets. in, Rome, 2019

IndexMundi (2020) Sunflowerseed meal production by country in 1000 MT. in, https://www.indexmundi.com/agriculture/?commodity=sunflowerseed-meal&graph=production

Náthia-Neves G, Alonso E (2021) Valorization of sunflower by-product using microwave-assisted extraction to obtain a rich protein flour: recovery of chlorogenic acid, phenolic content and antioxidant capacity. Food Bioprod Process 125:57–67

AlbeSlabi S, Mathé C, Framboisier X, Defaix C, Mesieres O, Galet O, Kapel R (2019) A new SE-HPLC method for simultaneous quantification of proteins and main phenolic compounds from sunflower meal aqueous extracts. Anal Bioanal Chem 411:2089–2099

Camargo D, Gomes SD, Sene L (2014) Ethanol production from sunflower meal biomass by simultaneous saccharification and fermentation (SSF) with Kluyveromyces marxianus ATCC 36907. Bioprocess Biosyst Eng 37:2235–2242

Wildermuth SR, Young EE, Were LM (2016) Chlorogenic acid oxidation and its reaction with sunflower proteins to form green-colored complexes. Compr Rev Food Sci Food Saf 15:829–843

Casoni AI, Gutierrez VS, Volpe MA (2019) Conversion of sunflower seed hulls, waste from edible oil production, into valuable products. J Environ Chem Eng 7:102893

Asaduzzaman AKM, Getachew AT, Cho Y-J, Park J-S, Haq M, Chun B-S (2020) Characterization of pepsin-solubilised collagen recovered from mackerel (Scomber japonicus) bone and skin using subcritical water hydrolysis. Int J Biol Macromol 148:1290–1297

Jokić S, Gagić T, Knez Ž, Banožić M, Škerget M (2019) Separation of active compounds from tobacco waste using subcritical water extraction. J Supercrit Fluids 153:104593

Prado JM, Lachos-Perez D, Forster-Carneiro T, Rostagno MA (2016) Sub- and supercritical water hydrolysis of agricultural and food industry residues for the production of fermentable sugars: a review. Food Bioprod Process 98:95–123

Park J-S, Jeong Y-R, Chun B-S (2019) Physiological activities and bioactive compound from laver (Pyropia yezoensis) hydrolysates by using subcritical water hydrolysis. J Supercrit Fluids 148:130–136

Pedras BM, Regalin G, Sá-Nogueira I, Simões P, Paiva A, Barreiros S (2020) Fractionation of red wine grape pomace by subcritical water extraction/hydrolysis. J Supercrit Fluids 160:104793

Iwassa IJ, dos Santos Ribeiro MA, Meurer EC, Cardozo-Filho L, Bolanho BC, da Silva C (2019) Effect of subcritical water processing on the extraction of compounds, composition, and functional properties of asparagus by-product. J Food Process Eng 42:e13060

Giombelli C, Iwassa IJ, da Silva C, Bolanho Barros BC (2020) Valorization of peach palm by-product through subcritical water extraction of soluble sugars and phenolic compounds. J Supercrit Fluids 165:104985

Mayanga-Torres PC, Lachos-Perez D, Rezende CA, Prado JM, Ma Z, Tompsett GT, Timko MT, Forster-Carneiro T (2017) Valorization of coffee industry residues by subcritical water hydrolysis: recovery of sugars and phenolic compounds. J Supercrit Fluids 120:75–85

Abaide R, Mortari SR, Ugalde G, Valério A, Amorim SM, Di Luccio M, d.F.P.M. Moreira R, Kuhn RC, Priamo WL, Tres MV, Zabot GL, Mazutti MA (2019) Subcritical water hydrolysis of rice straw in a semi-continuous mode. J Clean Prod 209:386–397

Sutanto S, Go AW, Ismadji S, Ju Y-H (2015) Taguchi method and grey relational analysis to improve in situ production of FAME from sunflower and Jatropha curcas kernels with subcritical solvent mixture. J Am Oil Chem Soc 92:1513–1523

Ravber M, Knez Ž, Škerget M (2015) Simultaneous extraction of oil- and water-soluble phase from sunflower seeds with subcritical water. Food Chem 166:316–323

Ravber M, Knez Ž, Škerget M (2015) Hydrothermal degradation of fats, carbohydrates and proteins in sunflower seeds after treatment with subcritical water. Chem Biochem Eng Q 29:351–355

Sluiter A, Hames B, Hyman D, Payne C, Ruiz R, Scarlata C, Sluiter J, Templeton D, Wolfe J (2008) Determination of total solids in biomass and total dissolved solids in liquid process samples. National Renewable Energy Laboratory 9:1–6

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of ash in biomass (NREL/TP-510–42622). National Renewable Energy Laboratory, Golden

Sluiter A, Ruiz R, Scarlata C, Sluiter J, Templeton D (2005) Determination of extractives in biomass. Laboratory Analytical Procedure (LAP) 1617:1–9

Hames B, Scarlata C, Sluiter A (2008) Determination of protein content in biomass. National Renewable Energy Laboratory, Golden, pp 1–5

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2008) Determination of structural carbohydrates and lignin in biomass. Lab Anal Proc 1617:1–16

Pazo Cepeda MV, Cocero Alonso MJ, Alonso E (2016) Pressurized water extraction and supercritical water hydrolysis as means to obtain ferulic acid from wheat bran. In: 8th Green Solvents Conference. Available on: http://uvadoc.uva.es/handle/10324/23501

Adamovic T, Tarasov D, Demirkaya E, Balakshin M, Cocero MJ (2021) A feasibility study on green biorefinery of high lignin content agro-food industry waste through supercritical water treatment. J Clean Prod 323:129110

Meinhart AD, Damin FM, Caldeirao L, de Jesus Filho M, da Silva LC, da Silva Constant L, Filho JT, Wagner R, Godoy HT (2019) Chlorogenic and caffeic acids in 64 fruits consumed in Brazil. Food Chem 286:51–63

Singleton V L, Orthofer R, Lamuela-Raventós RM (1999) [14] Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol 299:152–178

Ramachandran S, Singh SK, Larroche C, Soccol CR, Pandey A (2007) Oil cakes and their biotechnological applications–a review. Biores Technol 98:2000–2009

Geneau-Sbartaï C, Leyris J, F.o. Silvestre, L. Rigal, (2008) Sunflower cake as a natural composite: composition and plastic properties. J Agric Food Chem 56:11198–11208

Zabaniotou AA, Kantarelis EK, Theodoropoulos DC (2008) Sunflower shells utilization for energetic purposes in an integrated approach of energy crops: laboratory study pyrolysis and kinetics. Biores Technol 99:3174–3181

Alenezi R, Leeke GA, Santos RCD, Khan AR (2009) Hydrolysis kinetics of sunflower oil under subcritical water conditions. Chem Eng Res Des 87:867–873

Maravić N, Šereš Z, Vidović S, Mišan A, Milovanović I, Radosavljević R, Pavlić B (2018) Subcritical water hydrolysis of sugar beet pulp towards production of monosaccharide fraction. Ind Crops Prod 115:32–39

Miyamoto A, Chang K (1992) Extraction and physicochemical characterization of pectin from sunflower head residues. J Food Sci 57:1439–1443

Gagić T, Perva-Uzunalić A, Knez Ž, Škerget M (2018) Hydrothermal degradation of cellulose at temperature from 200 to 300 °C. Ind Eng Chem Res 57:6576–6584

Prado JM, Follegatti-Romero LA, Forster-Carneiro T, Rostagno MA, Maugeri Filho F, Meireles MAA (2014) Hydrolysis of sugarcane bagasse in subcritical water. J Supercrit Fluids 86:15–22

Torres-Mayanga PC, Azambuja SPH, Tyufekchiev M, Tompsett GA, Timko MT, Goldbeck R, Rostagno MA, Forster-Carneiro T (2019) Subcritical water hydrolysis of brewer’s spent grains: Selective production of hemicellulosic sugars (C-5 sugars). J Supercrit Fluids 145:19–30

Lu W, Chen X-W, Wang J-M, Yang X-Q, Qi J-R (2016) Enzyme-assisted subcritical water extraction and characterization of soy protein from heat-denatured meal. J Food Eng 169:250–258

Sereewatthanawut I, Prapintip S, Watchiraruji K, Goto M, Sasaki M, Shotipruk A (2008) Extraction of protein and amino acids from deoiled rice bran by subcritical water hydrolysis. Biores Technol 99:555–561

Ndlela S, De Moura J, Olson N, Johnson L (2012) Aqueous extraction of oil and protein from soybeans with subcritical water. J Am Oil Chem Soc 89:1145–1153

Singh PP, Saldaña MD (2011) Subcritical water extraction of phenolic compounds from potato peel. Food Res Int 44:2452–2458

Zulueta A, Esteve MJ, Frígola A (2009) ORAC and TEAC assays comparison to measure the antioxidant capacity of food products. Food Chem 114:310–316

Kumar S (2015) Analytical techniques for natural product research. CABI, Boston

Lachos-Perez D, Baseggio AM, Mayanga-Torres PC, Maróstica MR, Rostagno MA, Martínez J, Forster-Carneiro T (2018) Subcritical water extraction of flavanones from defatted orange peel. J Supercrit Fluids 138:7–16

Kim D-S, Lim S-B (2020) Semi-continuous subcritical water extraction of flavonoids from Citrus unshiu peel: their antioxidant and enzyme inhibitory activities. Antioxidants 9:360

Montesano D, Gallo M, Blasi F, Cossignani L (2020) Biopeptides from vegetable proteins: new scientific evidences. Curr Opin Food Sci 31:31–37

Hempel N, Petrick I, Behrendt F (2012) Biomass productivity and productivity of fatty acids and amino acids of microalgae strains as key characteristics of suitability for biodiesel production. J Appl Phycol 24:1407–1418

Frias J, Song YS, Martínez-Villaluenga C, De Mejia EG, Vidal-Valverde C (2008) Immunoreactivity and amino acid content of fermented soybean products. J Agric Food Chem 56:99–105

Li P, He W, Wu G (2021) Composition of amino acids in foodstuffs for humans and animals. In: Wu G (ed) Amino acids in nutrition and health: amino acids in gene expression, metabolic regulation, and exercising performance. Springer International Publishing, Cham, pp 189–210

Dabbour M, He R, Mintah B, Golly MK, Ma H (2020) Ultrasound pretreatment of sunflower protein: impact on enzymolysis, ACE-inhibition activity, and structure characterization. J Food Process Preserv 44:e14398

Grasso S, Omoarukhe E, Wen X, Papoutsis K, Methven L (2019) The use of upcycled defatted sunflower seed flour as a functional ingredient in biscuits. Foods 8(8):305

Funding

Open Access funding provided thanks to the CRUE-CSIC agreement with Springer Nature. This work was supported by the project VA277P18 and the EU-FEDER program (CLU-2019-04) financed by Regional Government (Junta Castilla y León) and FEDER.

Author information

Authors and Affiliations

Contributions

Conceptualization: Grazielle Náthia-Neves and Esther Alonso. Methodology: Grazielle Náthia-Neves. Writing—original draft preparation: Grazielle Náthia-Neves. Writing—review and editing: Grazielle Náthia-Neves and Esther Alonso. Supervision: Esther Alonso. Project administration, Esther Alonso. Funding acquisition, Esther Alonso.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Náthia-Neves, G., Alonso, E. Optimization of the subcritical water treatment from sunflower by-product for producing protein and sugar extracts. Biomass Conv. Bioref. 14, 1637–1650 (2024). https://doi.org/10.1007/s13399-022-02380-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13399-022-02380-w