Abstract

Tea (Camellia sinensis) is the most widely consumed beverage in the world, with an excellent source of bioactive compounds such as catechins, caffeine, and epigallocatechin. There is an increasing trend to extract these bioactive compounds to deliver them as value-added products. Generally, the extraction of polyphenols and other functional compounds from different parts of tea is carried out using different solvents (e.g., water, water–ethanol, ethanol, methanol, acetone, ethyl acetate, and acetonitrile). The extraction efficiency of functional compounds from tea depends on the type and polarity of the solvent as well as the applied process. Several conventional techniques, such as boiling, heating, Soxhlet, and cold extraction, are used to extract bioactive ingredients. However, these procedures are unsuitable for achieving high yields and biological activities due to the long extraction times of cold brewing and the high temperatures in other heating methods. Many efforts have been carried out in food and pharmaceutical industries to replace conventional extraction techniques with innovative technologies (e.g., microwave (MAE), ultrasonic (UAE), pressurized liquid (PLE), pulsed electric field (PEF), and supercritical fluid (SFE)), which are fast, safe, energy-saving, and can present eco-friendly characteristics. These innovative extraction techniques have proven to improve the recovery rate of phenolic-based antioxidant compounds from tea and increase their extraction efficiency. In this review, the application of novel processing technologies for the extraction of value-added compounds from tea leaves is reviewed. The advantages and drawbacks of using these technologies are also highlighted.

Similar content being viewed by others

Introduction

Tea (Camellia sinensis L.) is an ancient crop belonging to the Theaceae family. Although this evergreen plant originates from southeastern China, it has been widely distributed in countries with tropical and subtropical climate changes worldwide [1,2,3]. China’s tea spread to India, Japan, Russia, and Europe [4, 5]. According to [6], tea production was 5.79 million tons, of which China and India contributed 72%. Depending on how the fresh leaves are processed, there are various kinds of tea (e.g., green, white, black, yellow, oolong, Pu’er, or Pu-erh) [7]. Two varieties of tea, green and black, are extensively consumed worldwide [8, 9]. There are thousands of chemical constituents in tea, where the concentration present can be substantially affected by the different heredity (e.g., genetic strain), environmental factors (e.g., weather, soil, irrigation method, growth altitude, and harvest season), horticultural practices, and processing technologies and conditions [1, 10, 11].

Recently, there has been an increasing trend toward extracting bioactive compounds from tea to produce value-added products such as health supplements. Cold brewing of tea has also gained popularity due to increased consumer acceptance. In general, the extraction of polyphenols and other functional compounds from tea is carried out using a variety of solvents. Although water as a traditional solvent has been applied in most of the studies to extract polyphenols from green and black teas [12,13,14,15,16], the use of other solvents such as water–ethanol [17], ethanol [18, 19], methanol [20, 21], acetone [15, 22], ethyl acetate [23], and acetonitrile [15] has also been reported.

The extraction efficiency of bioactives without any chemical modification is not only a function of the type and polarity of the solvent used but is also influenced by the applied processing techniques for extraction [24]. Processing conditions such as tea: solvent ratio, particle size, agitation rate, and time/temperature have a significant effect on the extraction of bioactive compounds from tea [25]. Conventional techniques like boiling, heating, and reflux distillation are used for the extraction of bioactive ingredients from tea [26]. However, these conventional procedures are unsuitable for achieving high yields and biological activities due to the long extraction times and the high temperatures used [27].

Many efforts have been carried out to promote the use of innovative technologies such as microwave, ultrasound, pressurized liquid, pulsed electric field, and supercritical fluid with fast, safe, energy-saving, and eco-friendly characteristics that replace conventional solvent extraction methods (e.g., heat reflux) in food and pharmaceutical industries [26,27,28,29,30,31,32,33,34,35]. Applying novel technologies under mild processing conditions can decrease the impurity and structural changes of polyphenols sensitive to epimerization and oxidative oligomerization reactions and significantly enhance the extraction yield. In addition, these technologies also increase the solvent permeability rate in plant cells and the mass transfer coefficient of the target secondary metabolites [30]. Furthermore, there is a serious concern about tea by-products getting accumulated in the environment. Therefore, using economic and environmental approaches to reuse such agricultural and food processing waste seems necessary for the food industry.

The application of innovative extraction and separation systems such as nanofiltration membranes [2, 3], supercritical carbon dioxide [2, 36], microwaves [37, 38], ultrasound [39, 40], and pressurized liquid [3, 41] have been reported to significantly enhance the extraction of bioactive compounds from tea for the fortification of different foods such as bakery products [42]. Furthermore, studies have shown that tea can be a suitable substrate to produce activated carbon using combinations of chemical activation and microwave energy [43], as well as microwave and infrared energies [44]. Moreover, the discoloration process of dye wastewater by pulsed discharge plasma combined with charcoal derived from tea has been previously reported [45]. This paper provides a comprehensive summary of the literature published on the application of innovative processing technologies like ultrasound, microwave, pulsed electric field, pressurized liquid, and supercritical fluid to extract and recover bioactive compounds from tea.

Tea: Nutrition and Health Properties

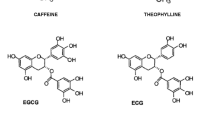

Tea, the most popular and oldest non-alcoholic beverage, has a unique flavor with some health benefits [46]. The global average consumption of this healthy functional drink is about 120 mL per day per person, while this value for Great Britain’s inhabitants is 4.5 times higher (≈540 mL/day) [47]. Tea primarily contains polyphenols, and catechins and theaflavins are tea’s primary and secondary polyphenols. Through the enzymatic browning by polyphenol oxidase, catechins present in tea leaves are converted to theaflavins during fermentation [48,49,50]. There are two optical isomers for each geometrical isomer of catechin (trans-catechins and cis-epicatechins), including (+ ,–)-catechin and (+ ,–)-epicatechin. Esterification of (–)-catechin with gallic acid (GA) can lead to the synthesis of (–)-gallocatechin-3-gallate (GCG), (–)-catechin-3-gallate (CG), epicatechin-3-gallate (ECG), and (–)-epigallocatechin-3-gallate (EGCG) from tea leaves [51, 52]. Moreover, four different kinds of theaflavins, namely theaflavin (TF), theaflavin-3-gallate (TF3G), theaflavin-3ʹ-gallate (TF3ʹG), and theaflavin-3,3ʹ-digallate (TF33ʹG), can be formed with the polymerization through oxidative coupling [53, 54]. The presence of other flavonoids (e.g., quercetin), alkaloids (theophylline, theobromine, and caffeine), long-chain aliphatic alcohols (e.g., policosanols), amino acids (e.g., glutamic acid, aspartic acid, and theanine), and minerals (e.g., fluorine, chlorine, calcium, and manganese) in various tea products has been demonstrated [5, 55].

The daily drinking of tea can significantly reduce the incidence rate of cancer types such as skin [56,57,58,59], breast [2, 3, 60,61,62,63], ovarian [64, 65], prostate [66, 67], lung [68, 69], oral [70, 71], colon [72, 73], stomach [70, 74], and pancreatic [75,76,77] induced by the consumption of alcohol and tobacco. The presence of polyphenols such as EGCG can notably inhibit the activation of carcinogens and, consequently, cancer initiation due to its antiradical and antioxidant activities and its implication in the detoxification system activation. The robust mechanism associated with the modulation in membrane organization, the formation of intercellular interactions with some functional macromolecules (e.g., proteins and nucleic acids), the epigenetic alteration, and the regulation of cellular replicative potential can highly limit the progress of carcinogenesis. This mechanism is accomplished by preventing the self-renewal, proliferation, and viability of the predominant tumor-initiating clones and, thus, the consequent growth [78]. Earlier, the effects of anti-mutagenic, anti-diabetic, anti-inflammation, anti-bacterial, anti-viral, anti-arthritis, anti-obesity, and neuro-protective of tea polyphenols have been comprehensively reported by other researchers [49, 79,80,81,82,83,84,85,86,87,88]. Additionally, the immune response by these bioactives was recently identified against severe acute respiratory syndrome coronavirus type 2 (SARS-CoV-2) [49, 89].

Several bioactive compounds, such as polyphenols and caffeine, can be extracted using conventional and novel extraction systems [23, 90]. The tea dust generally contains 2.5% decaffeinated tea, serving as a value-added source to extract bioactive compounds such as theanine [42]. This amino acid has many health benefits, such as relaxing and anti-tumor effects, learning capability enhancement, weight and nervousness decrease, reduction of blood pressure, triglyceride and cholesterol levels, immune system improvement, and inhibition of tobacco and nicotine addiction [42, 91,92,93,94,95,96].

Conventional Extraction of Bioactive Compounds from Tea

Selecting a proper extraction technique is essential for recovering the maximum amount of bioactives from tea. The conventional solid–liquid extraction (CSLE) methods are commonly used due to their ease and broad applications [97] and liability [97,98,99,100,101]. Soxhlet extraction is a standard technique for extracting phenolic compounds from tea using organic solvents such as methanol, ethanol, acetone, diethyl ether, and ethyl acetate. Flavonoids can be extracted with polar solvents such as ethanol, methanol, water, and combinations of these solvents [102,103,104,105]. The choice of solvent depends on the solvent’s ability to solubilize the solute, the extraction temperature, and the particle size of the solute [106].

Chang et al. [107] reported the possibility of extracting phenolics from green tea using co-solvents combined with carbon dioxide-assisted Soxhlet extraction. Although water is the commonly used solvent for extracting phenolics from tea, applying other non-polar green solvents (such as butanol, ethyl acetate, and ethanol) has been reported to extract bioactives and decaffeinating. It was reported in another study that using ethanol as a solvent improved the extraction of catechins than those extracted with water [36].

Goksu and Poyrazoglu [108] investigated the effect of using 80% methanol on total phenolic content (TPC) extraction from caffeinated and non-caffeinated green and black teas. There was a significant difference in TPC contents between caffeinated (159.4 mg/kg) and non-caffeinated (32.81 mg/kg) black teas. Similar results were observed for caffeinated (128.22 mg/kg) and non-caffeinated (43.16 mg/kg) green teas. Ethyl acetate, compared to n-butanol and n-hexane, was found to be a better solvent for isolating catechins from green tea [109]. The optimum extraction conditions with water were reported to be at the solid-to-solvent ratio of 1:30, the temperature of 80 °C, and the extraction time of 40 min for the extraction of catechins, which were then isolated using ethyl acetate and decaffeinated using citric acid. The authors reported that this treatment could lead to a substantial reduction in the caffeine content by up to 78.8%. The application of liquefied dimethyl ether removed the total caffeine from dried green tea leaves before extraction, whereas catechins were retained up to 56% [110].

Another study used the green, deep eutectic solvent (DES) to extract catechins from Chinese green tea [111]. The results showed that the efficiency values of catechins, ( +)-epicatechin gallate (EG), and (-)-epigallocatechin gallate (EGCG) were 82.7, 92.3, and 97.0%, respectively. Nadiah and Uthumporn [112] characterized catechins, caffeine, and gallic acid (GA) in tea leaves and spent tea. They evaluated the effect of various extraction conditions, such as boiling water, 50% ethanol concentration, and different extraction times. Compared to water, ethanol resulted in higher extraction efficiency of phenolic compounds from tea extracts, probably due to the higher polarity of ethanol that influenced the extractability rate.

The effect of particle size (intact and pulverized) and solvent type (methanol and acidified methanol) on the TPC, total flavonoid content (TFC), tannin content, and antioxidant activities of leaves of yellow, green, and black tea was studied by Kopjar, Tadić, and Piližota [113]. Pulverized tea leaves treated with acidified methanol exhibited the highest values of functionalities among the different tea leaves. The yellow tea leaves had higher bioactivity than the leaves of green and black teas. The antioxidant activities of extracts obtained from the yellow and green tea leaves were higher than those obtained from black tea leaves. Nibir et al. [114] have recently studied the antioxidant, and antimicrobial properties of aqueous extracts of flowery broken orange pekoe, broken orange pekoe, red dust, and green tea prepared with a solid-to-water ratio of 1:6. The aqueous extract of green tea exhibited promising anti-bacterial properties with a maximum level of phenolic content corresponding to 26.33 mg GA equivalent (GAE)/g extract.

Optimizing the operating parameters involved in the extraction process is essential to obtain bioactive compounds’ maximum efficiency and functionality from plant-based food matrices [25]. The optimization of phenolic compounds extracted from tea fruit peel biomass (TFPB) was carried out by Xu et al. [115]. The highest TPC (47.5 mg GAE/g) was obtained at the optimum conditions of 43% ethanol, 60 °C extraction temperature, and 33 min extraction time. Gallocatechin and epigallocatechin were the major phenolic compounds of TFPB. In another study, Kim et al. [116] evaluated the optimization of the TPC, antioxidant activity, and EGCG of green tea leaves at different ethanol concentrations (0–100%), extraction times (3–15 min), and extraction temperatures (10–70 °C). The maximum antioxidant activity (88.4%) was obtained using 57.7% ethanol at 70 °C for 15 min. Zielinski et al. [117] optimized the extraction process of phenolic compounds from white tea, and optimum conditions were 10 min extraction time at 66 °C and using 30% ethanol solution. Hung et al. [51] evaluated the effect of using water and ethanol at different concentrations (10, 50, and 95%) on the extraction of catechin and the antioxidant capacity of different C. sinensis twig. The results showed that the 50% ethanol extract had the highest level of phenolic (161.3 mg GAE /L) and flavonoid (278.9 mg quercetin equivalents/L) contents.

Although the conventional extraction of bioactive compounds from tea is easy and convenient, applying these methods implies adverse thermal effects on the extraction yield and quality with a significant expenditure of solvents and energy. Thus, the potential of using innovative extraction methods such as ultrasound-assisted extraction (UAE), microwave-assisted extraction (MAE), pulsed electric field (PEF), supercritical fluid extraction (SFE), and accelerated solvent extraction (ASE)/pressurized liquid extraction (PLE) has been reported to be an excellent alternative to produce tea extracts at industrial scale with an optimal expenditure of energy and chemicals. The application of some of these techniques for extracting bioactive compounds from tea is discussed in the subsequent sections.

Innovative Methods of Extraction

Ultrasound-Assisted Extraction

Ultrasound-assisted extraction (UAE) is one of the most emerging, efficient, and eco-friendly methods to disrupt cells to extract intracellular compounds from the cell matrix. UAE works on a simple principle of cavitation phenomenon where micro channels are formed in the sample by increasing the rate of diffusion of the solvent into the matrix [118,119,120,121] (Fig. 1). It is also referred to as the mechanical waves that can increase with pressure leading to the formation of cavities [106, 122]. With the increase in pressure, the cavities reach a specific limit beyond which they cannot absorb more energy and lead to the collapse of the bubbles when they reach maximum volume, thereby aiding in the disruption of the cells [122,123,124]. UAE can enhance the mass transfer rate of bioactive compounds during the extraction process from the plant tissues [125]. The application of this method reduces the extraction time and energy consumption and provides higher extraction yield [126,127,128,129,130]. Mixing the solvent using UAE will also increase the surface area under contact between the solvent and the cell matrix [118, 131]. Due to the reduced extraction times, UAE can decrease the thermal degradation of heat-sensitive bioactive compounds such as polyphenols [132].

Graphical representation of the cavitation formation and bubbles collapse accelerating the release of bioactive compounds from the plant cells (retrieved from Roohinejad et al. [133])

UAE has been in use for a long time to extract bioactive compounds from various tea leaves, as referred to in Table 1. Most of the research work was on green tea leaves [121, 134,135,136,137,138,139,140,141,142,143] and Black tea [31, 136,137,138, 143]. In addition, research has been carried out to extract bioactive from tea infusions [39], matte leaves [144, 145], tea solids [146,147,148], tea seeds [131], yellow tea [122], white tea [136, 137, 149], and Oolong tea [136, 137]. Solvents used for the extraction process were dependent on the targeted bioactive compounds for the process. Water remained the most used solvent for extraction [31, 121, 122, 138, 142, 143, 146,147,148] followed by methanol [138, 143, 144, 148, 149], ethanol [122, 138, 142, 147, 149], hexane [131, 144], and acetone [147]. Sometimes solvents like water/acetone and methanol/ethanol were used in combination for better yields. The solvent used for the extraction process should also be appropriately selected based on its selectivity for the target bioactive compound. For example, methanol served as the best extraction solvent for tannic acid, with a 19% higher yield [148].

UAE experiments were designed to understand the effect of various processing parameters like temperature, sonication time, power, and solid solvent ratio on the extraction efficiency of tea [39, 122, 131, 134, 140, 141, 144, 146, 147]. UAE was explored as an extraction method to extract compounds like catechins [134, 135, 138, 139, 142, 143], caffeine [136, 142, 143], tannic acid [148], oil [131], flavonoids [141], volatile compounds [137], theophylline and theobromine [136], theaflavins [138], antioxidant polyphenols [31, 140], total phenolic content [149], and antioxidant capacity [138] of tea extracts were analyzed with UAE. Among these, the catechins were found to be more stable in deep eutectic solvent (DES) extracts than in any other solvents (e.g., water, methanol, and ethanol) used for the extraction process [139]. In addition, UAE has been studied for increasing the total phenolic content and antioxidant capacity in cold-brewed black tea [31].

UAE effectively increased the extraction efficiency of catechin and decreased the extraction time and solvent consumption [134]. The application of dynamic UAE also reduced the oxidation and hydrolysis of the analytes because the system was airtight [143]. Using 50% acetone with sonication provided the highest extraction yield of 36% and 17% for EGCG [147] compared to conventional hot brewing at 33% and 12%. The highest extraction of total flavonoids with UAE (2,957.73 mg/L) was using ethanol as a solvent in comparison to conventional water extraction at ~ 500 mg/L [122]. Using water as a solvent, the extraction yield for green tea was 85% [121]. The solvent BGG-4 (betaine, glycerol, and D ( +) glucose) for UAE improved the extraction efficiency of the catechins (217 mg g−1) vs. UAE with water as solvent led to 100 mg g−1 for total catechins for green tea [139]. The optimum conditions for temperature included a range of 28 – 60 °C [39, 131, 134, 137, 141, 142, 146,147,148], power in the range 50–461W [39, 131, 140] and frequency in the range of 20 kHz—40 kHz [39, 122, 134, 148]. Sonication time for optimized conditions varied from as low as 10 s to as high as 120 min [39, 122, 131, 134, 137, 140,141,142, 146,147,148,149]. UAE is efficient at lower temperatures (60 °C), thereby minimizing thermal damage and maintaining the organoleptic characteristics of tea [39]. Application of UAE at high pressure, such as 90 to 338 kPa, increased the extraction yield to 200% and reduced extraction time and efficiency of extraction to 74% [145]. UAE significantly reduced the cold brewing time from 16 h to 30 min providing an energy-efficient method of extraction from black tea leaf matrix [31]. The application of UAE enhanced the extraction yield of EGCG to 15%, and the highest oxidative stability was observed in the nanoemulsion sample prepared with green tea with peanut oil [135]. The UAE with deep eutectic solvents resulted in an increase in the extraction yield of TPC, the total quantity of four main catechins, and the antioxidant activity of green tea polyphenolic extract [140]. Increasing the ultrasonic power from 10 to 50 W increased the extraction yield from 46.23 to 85.21%. The yield decreased by increasing the temperature [131].

The major advantages of using UAE compared to the conventional extraction methods include faster energy transfer, adequate mixing, faster response to process control systems, lesser energy consumption with average extraction time, reduction in thermal degradation, greater purity of the finished product, and fast return on investment [123]. The extraction efficiency usually differs from one tea to another due to the differences in the structure and the chemical composition of the leaf. Other factors, such as the turbidity of the plant tissue (tea leaves) and the starch granules, can also be influenced by the ultrasound energy applied and, thus, the effectiveness of the extraction [153]. UAE can be considered for shorter extraction time with minimal solvent usage for extraction of bioactives [131].

Microwave-Assisted Extraction

Microwave-assisted extraction (MAE) has received extensive attention as an alternative method for extracting bioactive compounds from plant-based food matrices [27, 125, 153,154,155]. The principle of MAE involves the propagation of non-ionizing electromagnetic waves between X-rays and infrared rays in the electromagnetic spectrum. These waves can penetrate the sample, interact with the compounds, especially polar compounds, and generate heat, which subsequently leads to changes in the structure of the cells [123, 125, 153, 156] (Fig. 2). The synergistic combination of heat and mass transfer, working in the same direction, is the primary cause of the process acceleration and the increased extraction yield [153, 157, 158].

Comparative illustration of conventional (A), ultrasound (B), and multi-mode microwave (C) applicator used to extract bioactive compounds from tea tissues (retrieved from Barba et al. [159])

MAE is a sequential process. The solvent initially penetrates the solid matrix of tea, followed by the structural breakdown. This aids in transporting the solutes rich in bioactive compounds out of the matrix. The solute migrates from the external solid surface to the bulk solution leading to the separation and the discharge of the extract containing bioactive compounds [153, 160, 161]. Then, the solvent interacts with the free water molecules present in the plant cells resulting in the rupture of the cell wall and aiding in the release of bioactive compounds from the cells to the solvent [162, 162, 163].

MAE was used to optimize better extraction efficiency of the bioactive compounds in various tea varieties which, includes green tea [3, 30, 37, 154, 155, 164, 165], black tea [27, 155, 164, 165], oolong [155, 164], decaffeinated green tea [166], mulberry tea [167], tea flower (C. morifolium) [151], decaffeinated Iranian green tea leaves [121], and tea blends consisting of white tea, green tea, mint, and peppermint [38]. MAE was suitable for producing green tea extracts rich in polyphenols [30].

MAE was used for the extraction of polyphenols [3, 30, 37, 164, 166, 168], tea flavonoids [11], antioxidant and anti-diabetic properties of tea extracts [151], and total phenols recovery [27, 94, 95, 165, 169]. The bioactive compounds extracted using MAE include catechin and epicatechin [38, 154], caffeine [38, 155, 170], and tea saponins from the oil—tea camellia seed cake [171]. The optimized temperature conditions used for MAE were in the range of 80–200 °C [3, 30, 94, 95, 151, 152, 164, 169]. The temperature was considered the primary variable [3, 121] for caffeine and catechin extraction using MAE [152]. However, even though a higher temperature was used, MAE was only carried out for a short period ranging from a minimum of 30 s to a maximum of 60 min [11, 27, 30, 37, 38, 94, 95, 151, 152, 154, 155, 166,167,168,169, 171] and microwave power in the range of 150–900 W [11, 27, 30, 38, 94, 95, 121, 151, 152, 155, 165,166,167,168, 170]. The solvent composition, solid-to-solvent ratio, extraction temperature and time, microwave power, stirring speed, pressure, and surface area of contact are the critical parameters affecting the extraction of bioactive compounds in an MAE process [88, 153, 156]. The order of influence of these parameters was deduced to be irradiation time > intensity > tea to the solvent ratio [166].

The solvent used for the extraction depends on the solvent’s penetration and interaction with the targeted bioactive compounds [153, 172]. Some of the solvents used for the extraction process were water [30, 37, 121, 151, 169], ethanol [37, 38, 94, 95, 152, 168, 169], and acetone and methanol [37, 169]. The solvent should also have the capacity to absorb the microwave energy, but absorption depends on the boiling point, microwave energy dissipation, and dielectric properties of the solvent. Depending on the solvent volume, the heating time would be altered [27]. The ethanol concentration was the most influential parameter for the extraction of polyphenols. The enhancement of product recovery in MAE is due to the heating effect of the microwave [168]. MAE can be considered one of the fastest extraction methods for polyphenols and caffeine [37]. The caffeine recovery in the tea samples was found to be in the range of 88.2% to 99.3% [170] using dynamic MAE. MAE’s extraction efficiency was more than 95% [11, 94, 95, 121] for the recovery of catechins and derivatives within a short time [3, 11, 154]. It also had a good recovery process compared to conventional methods [152]. MAE-assisted green tea extracts were more concentrated in total polyphenols (26%) compared to black tea (16%) [165]. The yield and efficiency of the extraction increase proportionally to the time and the microwave applied power and decrease beyond a specific limit mainly due to the increase in temperature. Microwave power is a crucial parameter to optimize the extraction process. The mixing process is an essential consideration in the optimization process since it is directly related to the mass transfer in the solvent. The surface area under contact also enhances the efficiency of the extraction process. The finely powdered samples usually have a large surface area aiding in a better contact surface between the plant matrix and the solvent, thereby deepening the penetration of the microwaves [153, 172]. The extraction time and the irradiation power were the parameters that should be reduced to decrease the degradation of polyphenols [168].

Many researchers have reported that the MAE is more effective than the conventional extraction methods (e.g., solid–liquid extraction, extraction at room temperature, maceration, reflux extraction) in extracting bioactive compounds from green teas at ambient temperature [11, 37, 173]. The results of the bioactive extraction from tea leaves using different operating conditions of MAE are summarized in Table 2. MAE can be used for industrial applications with minor modifications in the sample size and solvent-to-solid ratio [168]. MAE was the fastest extraction method, involving a rapid extraction of phenols [164]. The extraction time was reduced to more than eight times when compared with HRE (hot reflux extraction), two times when compared to UAE (ultrasound-assisted extraction), and five times when compared to SFE (supercritical fluid extraction). The extraction yield was increased by 17.5% compared to HRE. The energy consumption was ¼ when compared to UAE, with a 40% increase in the total phenolics. The study concluded that MAE only required a shorter time and lesser energy consumption and provided higher extraction selectivity and extraction yield [94].

MAE is an easy, convenient [167], fast, and reliable method for the recovery of catechins and epicatechins [154]. It can be considered one of the effective methods of extraction [166, 169] due to its targeted extraction of bioactives and thereby enhancing the antioxidant quality of the extracts [168]. Compared to the UAE, the extraction efficiency of bioactives was higher with MAE [121] and more efficient at higher temperatures. MAE also led to a higher recovery of total phenolic compounds, compared with the standard brewing techniques, without affecting the antioxidant potential of the tea [27]. MAE reduced the extraction time, energy consumption, and environmental burden [30], making it an alternative technology for the extraction of bioactives from tea.

Pulsed Electric Field

Pulsed electric field (PEF) is a non-thermal technology that extracts targeted bioactive compounds from tea. This method works on the simple principle of cell wall disruption, increasing the cell matrix’s permeability for efficient extraction. PEF is one of the emerging technologies in the process industries and is considered competitive compared to the other processes concerning cost-effectiveness [174]. For the extraction process, the tea sample is placed between two electrodes, followed by the application of high electric field pulses for a concise duration (ns to µs) [34, 35, 175,176,177,178,179,180] (Fig. 3). Currently, high-intensity PEF (> 10 kV/cm) is used as a preservation method for the inactivation of microorganisms due to the breakage of cell membranes [181, 34, 35, 182, 183] and in turn increases the shelf life of the food [34, 35, 179, 184]. The size and formation of pores can be reversible or irreversible, depending on the pulse intensity, the electric field strength, the number of pulses, and the treatment time [33]. The effect of various operating parameters involved in PEF technology on the extraction efficiency and functionality of tea’s bioactive compounds are summarized in Table 3.

PEF treatment induced pores on the tea matrix’s surface and facilitated the solvent’s penetration and the polyphenols’ migration [187]. Electroporation efficiency is also controlled by the electric field intensity [180]. The degree of disintegration of the cell matrix also depends on treatment time, and intensity of the electric field applied. Lower intensities take a longer time for the electroporation and vice versa [180]. Thus, increasing the intensity of electric fields increases the extraction yield proportionately [33, 177]. For the solvents used for PEF extraction, the conductivity and solubility of targeted compounds in the solvent are critical. The increase in conductivity of the solvent will increase the extraction efficiency due to enhanced electroporation [177]. In addition, He et al. [171] reported that increasing the solvent concentration can reduce the concentration of the bioactive compounds bound to the sample, making the dissolution process easier. Other parameters for optimization include the pulse duration, the number of pulses, and the pause between the pulses [180]. The longer pulse duration for the extraction was more effective compared to a short duration. The longer pulse duration increases the permeation of the cells but negatively leads to the decomposition of the extracts. The effect of the pulse width varies depending on the electric field strength, types, quality, and contact parameters, such as the geometry and the size of the samples [180]. The extraction kinetics strongly depends on the interval between the pulses and higher field strengths [180].

By using PEF for extraction, tea’s aromatic compounds, polyphenols are protected from damage [34, 35, 188], and its color, taste, and aroma remain unchanged [34, 35, 39, 179, 186, 188]. Traditionally, PEF has been used in the extraction and retention of polyphenols from green tea [179, 187], black tea [186], Puer tea [174], and green tea infusions [33,34,35]. PEF retained more bioactive compounds and color than conventional heat treatment [34, 35]. PEF is mainly used to extract polyphenols, catechins, and free amino acids [35]. The extraction yields for polyphenols ranged from 22 to 32% [179, 180, 186] and the extraction rate was observed to increase ~ 2 times without degrading or altering the phenolic profiles [187]. Using PEF beyond a specific limit, had a loss of < 10% in volatiles and but it increased amino acid content by 7.5% [34, 35]. On the contrary, it reduced the loss of aromatic compounds due to the volatilization in instant tea [186]. Additionally, PEF treatment has been known to improve the taste and aroma of tea samples and characteristics like the natural aging of tea. The high voltage of PEF assisted in artificial aging, thus improving the taste with an accelerated aging process. It can also be used to rapidly age unfermented Pu Erh tea [174]. Overall, this extraction technique provided the maximum extraction yield of polyphenols without destroying their activities [179] compared to hot brewing methods. Moreover, PEF has been investigated as an alternative to drying processing before extracting polyphenols [187].

a–d Schematic illustration of the electroporation mechanism in the cell membrane exposed to an electric field (retrieved from Roohinejad et al. [133])

A longer shelf life of infusions was achieved (about 90 days) when storage temperature at 4 °C was considered along with PEF treatments [34, 35]. A slight temperature increase was recorded during the treatment at ≤ 10 °C [33]. Effective log reductions were observed for Escherichia coli and Staphylococcus aureus, at 38 kV/cm and less treatment time 16–200 µs [34, 35]. PEF is a time and energy-efficient extraction method. The advantages of using PEF include minimal energy consumption, uniform transmission, and quicker processing [174, 189]. PEF has not been extensively researched compared to other technologies reviewed in the study due to economic limitations. More validation and further research into the extraction using PEF should be studied and analyzed to understand the underlying effects of PEF on tea.

Supercritical Fluid Extraction

Supercritical fluid extraction (SFE) is one of the alternative technologies used to extract bioactive compounds from tea leaves [88, 106, 190, 191]. SFE works based on the principle of the supercritical properties of fluids like CO2 and water. SFE is a two-step process, extraction, and separation. The system consists of an extraction chamber, wherein the tea samples are placed inside the supercritical fluid. The samples are then subjected to a specific temperature and pressure to extract the bioactive compounds. After the extraction process, the mixture containing the bioactive compound passes through the separator for the separation process (Fig. 4) [191].

Graphical illustration of the SFE method used to extract bioactive compounds from tea (retrieved from [192]

SFE was used in the extraction of theophylline, theobromine, and caffeine [193,194,195,196,197], safrole and allylbenzenes [198], monoterpenes [199], triterpenic acids [200], alkaloids [195], phenolics [196], volatile compounds [201], and oil [202]. Japanese tea [203], Sassafras tea [198], Mate (IIex paraguariensis) leaves [193, 197, 199], Malaleuca alternifolia Cheel leaves [204], herbal tea [200], Hedyotis diffusa and Hedyotis corymbose, Assam tea—seeds (C. sinensis var. assamica) [202], Korean tea [205], green tea [194, 196, 201, 205,206,207] were all studied for the extraction of various bioactive compounds using SFE from tea leaves.

The temperature and pressure can be adjusted based on the dissolving power of the target bioactive compounds [106, 208], and they serve as critical factors for the extraction system [197, 209]. This is because the density of the solvent and solubilization of the solute will depend on the pressure applied to the system. However, increasing the pressure beyond a specific limit will negatively impact the extraction process as it might reduce the diffusion rate of the solvent. This will hinder the extraction resulting in lower yields [209]. Pressure is also a critical parameter in the SFE extraction [190], and most pressure conditions ranged from 7.4 to 88 MPa. Different flow rates for CO2 were employed, and there is no guiding explanation involved why the flow rates were different for each sample; one detail can be attributed to the difference in the system used, and the flow rate ranges from 0.9 g to 1250 g / min [190, 195,196,197, 201,202,203,204,205,206]. Extraction curves further helped prove that the extraction rate increased with pressure [210].

Diffusivity and apparent volume of solvent increase with temperature, while density decreases with temperature. The extraction process ranged from 10 to 540 min, with temperatures ranging from 40 to 100 °C [190, 193,194,195,196,197,198, 201,202,203,204,205,206,207]. Depending on the sample matrix, varying time–temperature combinations were employed under the SFE extraction process. A decrease in the temperature conversely increases the density and the solvation of the solutes. This is called a “crossover effect,” where the high temperatures result in lower yields, and lower temperatures provide higher extraction yields. Thus, the author states that the increase in kinetic energy (due to temperature) will be directly proportional to the diffusion rate of CO2 [209]. However, Natolino et al. [210] state that temperature had a negligible effect on extraction kinetics.

SFE has increased the extraction efficiency and preserved organoleptic characteristics of the bioactive extracts. The supercritical fluid commonly used in SFE is CO2 (with high purity) as it is non-toxic and non-flammable under low critical pressure, is cost-effective, and allows easy removal of the supercritical fluid from the extracts [123, 207]. Generally, the co-solvent used in the extraction process has intermediate volatility between the supercritical fluid and the extracted bioactive compounds. This aids in enhancing the solubility of the bioactive compound in the supercritical fluid. The type of supercritical fluids is the rate-determining step of the entire SFE process. The bioactive compounds (solutes) of interest in tea, such as polyphenols and alkaloids, are less soluble in carbon dioxide, and hence increasing the pressure increases the solubility of the solutes. In addition, co-solvents (isopropyl alcohol, ethanol, n-hexane, pentane, heptane, toluene, methanol, acetone) [203] can also be used to increase the solubility of polar compounds during the extraction process. For the optimization and strong interaction of the matrix and the bioactive compounds [209] the co-solvent type and concentration, like ethanol and water, during the initial pre-treatment used were the critical parameters for the extraction process of green tea [207]. Table 4 provides a summary of the extraction process of SFE in the extraction of targeted bioactives in tea over the years.

Ethanol served as a suitable solvent for extracting methylxanthines [197]. Solvents such as ethanol [196, 197, 200, 206, 207], methanol [193, 203], hexane [204], and water [195, 205, 206] were used as the solvent phase in the extraction process. However, water was experimentally proved to be the best solvent for the selective extraction of caffeine from green teas with a selectivity of 0.88 compared to the selectivity of ethanol (0.24) [195]. SFE uses a lesser solvent for extraction [197]. The extraction success depends on selecting the conditions that can enhance the extraction of the desirable compounds by regulating the solvation power, avoiding the influence of other materials, and reducing the co-extraction of impurities [213]. The sample matrix of the leaves played a fundamental role in the extraction process for SFE [204]. The solvent removal from the system also depends on several factors, such as the solubility of the solute, the interactions of the solute-solid matrix, the localization of the solute in the matrix, and its porosity.

The extractability with SFE was found to be 57%, 68%, and 94% for theophylline, theobromine, and caffeine from mate tea [197], and a recovery of > 96% for safrole and other alkylbenzenes in Sassafras teas [198]. SFE has been employed to remove caffeine in green tea by avoiding the extraction of antioxidants from the tea matrix [214]. For green tea, SFE showed a maximum removal of caffeine (91.5%) and retention of 80.8% of catechins [206]. The caffeine content in green tea was minimized to 2.6%, and 37.8% of ECGC was lost in the process [207].

Most of the process optimization was based on the maximum extraction of caffeine (54%) and EGCG (21%) [195]. The extraction rate was 36.1% for caffeine and 40.6% for catechins in green tea [196]. The increased amount of caffeine extracted using SFE was accompanied by decreased volatiles present in green tea [201]. The solubility of the extracted caffeine was found to be lower in green tea [194] as compared with pure caffeine (61 times higher). The combination of UAE and SFE extraction methods also resulted in higher extraction yields (15–16%), decreasing the extraction time to 95 min in comparison to 180 min of heat reflux extraction and 135 min of UAE, and aiding in minimizing the amount of solvent used (43 mL) [200]. SFE was efficient for extracting caffeine and theobromine compared to extraction rates of other polyphenolics from mate tea [193]. Chlorophyll was sometimes co-extracted with caffeine, and further processing was required to recover the chlorophyll to improve the quality of tea [196]. Additionally, antioxidant activity improved with the highest extraction yield of 50% (Natolino, Da Porto, and Scarlet 2022) in tea after SFE. The maximum TPC, TFC, tannin content, and total antioxidant activity was 131.24 mg GAE/100 mL, 194.60 mg QE/100 mL, 49.99 mg TAE/100 mL, and 262.23 µmol TEAC/100 mL for Camellia sinensis [190]. Supercritical CO2 extraction efficiently extracted oil from Assam tea seeds with a maximum of TPC (15.89 mg GAE/100 g) and scavenging activities (IC50=15.35 g/L for DPPH and 87.23 g/L for ABTS) [202]. SFE can achieve higher extraction efficiency and yield [203] within a shorter extraction time [197, 198]. The selectivity of CO2 for caffeine extraction was much higher [197, 199] than tea’s other bioactive compounds.

Pressurized Liquid Extraction

The pressurized liquid extraction (PLE) process uses elevated temperature and pressure to extract bioactive compounds from tea [215]. Due to the high temperature used, the structural bonds in the bioactive compound weaken, resulting in the rapid extraction of the selective bioactive compounds from the tea matrix [41]. The critical factors contributing to the extraction process include the high solubility of the bioactive compounds in the solvent and the high diffusion rate caused due to the weakening of the bonds [208, 216]. This extraction process has been explained in detail elsewhere [217,218,219]. The solvent forms a layer around the tea to enhance the desorption of the bioactive compounds from the matrix site of the tea leaves [220]. Furthermore, the bioactive compounds diffuse into the organic solvent and finally get distributed into the extraction phase. The efficiency of the extraction depends on the nature of the matrix and the compound, the location of the targeted bioactive compound inside the matrix [218, 220], solubility, and the diffusion rates [218, 221, 222]. Pressurized solvent extraction (PSE), pressurized hot-water extraction (PHWE), subcritical water extraction (SCWE), accelerated solvent extraction (ASE) technology, and superheated water extraction (SHWE) are different forms of PLE used for the extraction [123, 218]. PLE is typically used to extract and isolate caffeine and catechins from tea. The PLE had the highest recovery rates of target bioactives but also ensured a maximum degree of accuracy due to automation [215].

Temperature and pressure are major parameters of concern for PLE. The temperature in the process affects the efficiency and sensitivity of detecting the targeted bioactive compounds. Higher temperatures improve extraction efficiency by disrupting the bonds, eliminating interactions, and lowering the activation energy required for the desorption process. It also decreases surface tension by altering the sample’s wettability and solubility [218]. However, increasing the temperature might impact negatively by extracting non-targeted bioactive compounds, resulting in decreased selectivity. On the other hand, elevated pressure in the process affects the solvent’s boiling point, causes cell disruption, and enhances the mass transfer rate. The elevated pressure also assists in controlling the challenges related to the bubbles formed within the matrix that hinder the solvent from reaching the bioactive compounds. This boosts the bioactive compounds’ solubility and desorption rate [218].

Several experimental procedures to extract catechins [28, 29, 41, 223], epicatechins [41], caffeine [28, 29, 224,225,226], phenolics, ligands, carotenoids, oils, lipids, essential oil, and nutraceuticals [218] using PLE from tea has been reported. Various types of tea products like green tea [223, 225, 226], black tea [41], fermented and non-fermented teas [41], mate leaves [144, 216], herbal tea [215, 218], and eagle tea [215] were studied. Solvents such as water [41], methanol [41, 144], ethanol [29, 41], ethyl acetate [41, 144], ethyl lactate [28, 29], n-hexane, toluene, dichloromethane, acetone have been also carried out with PLE [144].

For the extraction processes, the temperature range was between 275 °C [28, 29, 41, 144, 215, 216, 226] to a lowest at 40 °C [225] and some maintaining high pressure to reach 275 °C [224]. The best solvents that can be used for PLE include methanol [41, 144, 224], water [28, 226], ethyl lactate [28, 29], n–hexane [227] for enhanced extraction of bioactive compounds. When a combination of water and ethyl lactate was used as extraction solvents, the yields were 3.5 times and 1.5 times higher than using them separately with water and ethyl lactate. PLE also aided in 26–36% removal of catechins from the tea leaves [28] with 53–76% caffeine recovery. In terms of recovery rates, there was 3.21% for catechin and 2.96% for epicatechin from black tea [41].

Most of the extraction time ranged from a lowest of 5 min [215, 227] to a highest of 20 min [28, 29, 41, 144, 216, 225, 226]. However, a study with micro pressurized extractions where the treatment required only 20 s (5–100 mg sample) for rapid solid sample analysis [224]. The optimized pressure also had a range between 3 and 10 MPa [29, 41, 144, 215, 216, 224,225,226,227].

PLE was demonstrated to be an alternative method for the extraction of caffeine [225] but not great for tea because it squeezes out the soft leaf matrix making the diffusion of caffeine and hindering the penetration of the solvent into the matrix. Ethyl lactate was a suitable solvent for isolating caffeine from green tea leaves [28, 29]. PLE is considered a selective method of extraction since it reduces the co-extraction of catechins during the selective extraction of caffeine [28]. The use of high temperature enhanced the extraction of polar compounds [144, 216], and the polarity of the solvent also had a higher effect on the extraction process [216]

The extraction process of PLE is analogous to the liquid–liquid extraction process [226]. Some studies showed no significant changes in palmitic acid, phytol, stearic acid, squalene, and vitamin E extraction from tea [144]. A significant advantage of PLE is that it prevents tea leaves from being damaged by oxygen and light during the process, and it is highly automated to ensure precision [215] and rapid extraction results for complex samples. PLE could also be used for the regular detection and extraction of pesticide residues faster and simpler [227]. PLE is better and faster with a lower sample and solvent technique [224]. Although it has many advantages, one of the significant drawbacks of PLE is thermal degradation due to elevated temperature [215]. The results of PLE application under different processing conditions to extract-specific bioactive compounds from various species of tea are shown in Table 5.

Innovative Processing Technologies: Advantages and Drawbacks

Summarizing all the technologies, UAE has been proven to have higher extraction efficiency at lower temperatures. The most critical parameters affecting extraction in UAE include sonication power, frequency, solvent-to-solid ratio, temperature, and sonication time [146, 152]. One of the limitations of using UAE is when the sample is exposed to UAE for a longer time, it can significantly affect the process since it generates heat, which leads to the decomposition of the thermo-sensitive compounds. Thus, selecting an appropriate sonication time plays an important role in the extraction process [228]. Conversely, MAE is considered a rapid alternative method that couples microwave heating with chemical extraction techniques. MAE is most employed for extraction and pre-treatment, wherein time, temperature, and pressure play the most influential role in the process. The major advantage of using MAE is to extract healthy-functional constituents from tea, resulting in higher extraction yield with a shorter time, lower energy consumption, and higher extraction selectivity.

PEF serves as an effective method that is more specific for the extraction of intracellular compounds without the use of heat and pressure. In addition, it can be used as a method for the inactivation of the microorganisms present in the tea, depending on the intensity of the electric field strength applied. The effectiveness of the process depends on factors such as the electric field intensity, pulse wave shape, pulse frequency, polarity, solvent selection, the ratio of solute to solvent, pulse duration, and the treatment temperature and time. The electroporation mechanism assisted the extraction to a greater extent with the optimized conditions. The extraction efficiency of PEF falls in the range of 27 to 32%. PEF can be a promising method for large-scale extractions and for extending tea extracts’ shelf life. In addition, PEF can help preserve the color of the product and its bioactive properties without affecting the properties.

Comparatively, SFE was more specific for the extraction of caffeine from tea. The critical parameters in SFE include the temperature and pressure, the flow rate of CO2, and the matrix composition of tea leaves. This method assisted in the highest retention of catechins in the cells rather than their extraction. SFE is regarded as a method for extracting phytochemicals, and the recovery and extraction rate are found to be more than 90% with a longer extraction time. This method of extraction is found to be better with the use of organic solvents. SFE might be an expensive extraction method compared to UAE, PEF, PLE, and MAE.

Furthermore, PLE can rapidly extract the targeted bioactive compounds, as there is a higher chance of improved wetting of the molecules present inside the tea leaf matrix by the organic solvent. The temperature and the pressure play an influential role in the extraction process. The higher temperature and pressure improved the solubility of the targeted bioactive compound during the extraction process. The method uses a high temperature, thus making it unsuitable for thermo-sensitive compounds. It helps in the faster extraction of bioactive foods like caffeine and catechins. However, reagents and pressure preparations are expensive to be used on a large scale in the industry; hence, further research is needed for determining alternative cheap reagents.

From the review, it can be concluded that SFE is most widely used for the selective removal or extraction of caffeine and has an extraction efficiency of ~ > 80%. Moreover, when catechins and caffeine need to be extracted with higher recovery rates, PLE is commonly preferred since it has a recovery range of 50 to 90% for catechins and 26 to 95% for caffeine. MAE and PEF were employed for maximum extraction yields for total phenolic compounds (~ 35%). In addition, PEF was also used for improving the extraction of free amino acids. UAE provided favorable conditions for the extraction of catechins and flavonoids, including theobromine, theophylline, and theaflavins.

Considering the review, each method of extraction has advantages in specific ways. The mass transfer is increased due to the bond breakage between matrix and bioactive compounds for all the extraction methods. The extraction yield SFE ranks higher than other methods discussed but with the disadvantage of longer extraction time. MAE and UAE are the two best extraction methods with water as a solvent and high extraction efficiencies. Both methods have lower extraction time for phytochemicals; however, based on temperature, MAE could be used as an extraction method if a higher temperature is preferred, and UAE can be used if a lower temperature is preferred. PEF, on the other hand, could be opted to increase the extraction efficiency and retain the bioactives with an increased color retention and shelf life. SFE and PLE could be effective methods for selectively extracting caffeine. For industrial-scale applications, PEF, PLE, and SFE can be used as a continuous process for extraction, whereas UAE and MAE can only be used as a batch process. In addition, SFE, PLE, and PEF also require high initial capital investments. Comparing all the technologies, both UAE and MAE are two technologies that can have a broader spectrum of commercialization in terms of acquiring process equipment and, at the same time, attaining higher extraction efficiency.

The review overall had a broader view of the novel methods used to extract bioactive compounds from tea. With all the conventional techniques used for the extraction process from tea, it was evident that the novel processing technologies provide better results owing to technological advancements. However, each method has different advantages, which are specific to the method and have fewer limitations for the extraction process. However, the study is insufficient to conclude one extraction process, as many variables, such as the type of the sample, the experimental conditions, and many other process parameters, play a major role in selecting an extraction process. More extensive studies should be directed toward the extraction techniques, and comparative studies with other novel extraction technologies need to be carried out from the quantity and quality viewpoints.

Conclusions and Future Directions

Over the last two decades, novel innovative processing technologies (e.g., UAE MAE, PEF, SFE, and PLE) have been used as an alternative technology to replace conventional extraction methods due to their high efficiency and effectiveness in extracting bioactive compounds from tea. Several studies discussed in the present review have highlighted the application of these novel technologies to various teas. Applying these technologies over conventional solvent extraction techniques improves extraction time and temperature, the number of used solvents, and extraction efficiencies. Moreover, food-processing industries are taking sustainable initiatives to fully utilize the possibility of environmental-friendly novel technologies for extraction.

The application of novel technologies for the extraction of bioactive compounds from tea would provide a sustainable solution for tea industries and generate value-added functional ingredients that have commercial value. Additionally, novel-processing technologies might be used to tailor foods with added or enhanced functional and nutritional values, lowering the carbon footprint and substantially reducing the water volumes used in industrial heat transfer processes.

The biggest drawback to applying novel technologies could be consumer acceptance, capital investments, and reproducibility. During the extraction process, the food matrices are subjected to various combinations of pressure, time, and temperature as the main parameters involved in the extraction technique. Improper application of process parameters can strongly initiate Maillard reactions, leading to the formation of carcinogenic substances. Hence, every food sample needs to be studied uniquely, and the process variables should be optimized. Also, the functionality of the bioactive compounds extracted using various novel techniques must be examined before commercial approval. In brief, novel technologies can produce high-quality bioactive compounds with minimal environmental impact. Even though high investments are generally required to carry out-tailor made research by industries on these novel technologies, the results from fundamental research are very promising.

References

Paiva L, Lima E, Motta M, Marcone M, Baptista J (2021) Influence of seasonal and yearly variation on phenolic profiles, caffeine, and antioxidant activities of green tea (Camellia sinensis (L.) Kuntze) from Azores. Appl Sci 11(16):7439

Sanz V, Flórez-Fernández N, Domínguez H, Torres MD (2020) Clean technologies applied to the recovery of bioactive extracts from Camellia sinensis leaves agricultural wastes. Food Bioprod Process 122:214–221

Sanz V, Flórez-Fernández N, Domínguez H, Torres MD (2020) Valorisation of Camellia sinensis branches as a raw product with green technology extraction methods. Current Research in Food Science 2:20–24

FAOSTAT (2015) Available from http://www.fao.org/faostat/en/#search/tea. Accessed 2 May 2021

Sharangi AB (2009) Medicinal and therapeutic potentialities of tea (Camellia sinensis L.) - A review. Food Res Int 42(5–6):529–535

FAOSTAT (2021) Crops and livestock products: Tea. Retrieved on August 4, 2021, from FAO Departments and Offices website

Chen S, Wang C, Tsai C, Yang I, Luo S, Chuang Y (2021) Fermentation quality evaluation of tea by estimating total catechins and theanine using near-infrared spectroscopy. Vib Spectrosc 115:103278

Khan N, Mukhtar H (2013) Tea and health: studies in humans. Curr Pharm Des 19(34):6141–6147

Samanta S (2020) Potential Bioactive components and health promotional benefits of tea (Camellia sinensis). J Am Coll Nutr 41(1):65–93

Ahmed S, Griffin TS, Kraner D, Schaffner MK, Sharma D, Hazel M, Cash SB (2019) Environmental factors variably impact tea secondary metabolites in the context of climate change. Front Plant Sci 2019:939

Sultana T, Stecher G, Mayer R, Trojer L, Qureshi MN, Abel G, Popp M, Bonn GK (2008) Quality assessment and quantitative analysis of flavonoids from tea samples of different origins by HPLC-DAD-ESI-MS. J Agric Food Chem 56(10):3444–3453

Khokhar S, Magnusdottir SGM (2002) Total phenol, catechin, and caffeine contents of teas commonly consumed in the United Kingdom. J Agric Food Chem 50(3):565–570

Larger PJ, Jones AD, Dacombe C (1998) Separation of tea polyphenols using micellar electrokinetic chromatography with diode array detection. J Chromatogr A 799:309–320

Liang Y, Lu J, Zhang L, Wu S, Wu Y (2003) Estimation of black tea quality by analysis of chemical composition and color difference of tea infusions. Food Chem 80(2):283–290

Perva-Uzunalić A, Škerget M, Knez Ž, Weinreich B, Otto F, Grüner S (2006) Extraction of active ingredients from green tea (Camellia sinensis): extraction efficiency of major catechins and caffeine. Food Chem 96(4):597–605

Obanda M, Owuor PO, Mang’oka R (2001) Changes in the chemical and sensory quality parameters of black tea due to variations of fermentation time and temperature. Food Chem 75(4):395–404

Sökmen M, Demir E, Alomar SY (2018) Optimization of sequential supercritical fluid extraction (SFE) of caffeine and catechins from green tea. J Supercrit Fluids 133:171–176

Asadi SY, Parsaei P, Karimi M, Ezzati S, Zamiri A, Mohammadizadeh F, Rafieian-kopaei M (2013) Effect of green tea (Camellia sinensis) extract on healing process of surgical wounds in rat. Int J Surg 11(4):332–337

Opie SC, Robertson A, Clifford MN (1990) Black tea thearubigins—their HPLC separation and preparation during in-vitro oxidation. J Sci Food Agric 50(4):547–561

Kerio LC, Wachira FN, Wanyoko JK, Rotich MK (2013) Total polyphenols, catechin profiles and antioxidant activity of tea products from purple leaf coloured tea cultivars. Food Chem 136(3–4):1405–1413

Yao L, Jiang Y, Datta N, Singanusong R, Liu X, Duan J, Raymont K, Lisle A, Xu Y (2004) HPLC analyses of flavanols and phenolic acids in the fresh young shoots of tea (Camellia sinensis) grown in Australia. Food Chem 84(2):253–263

Wang H, Helliwell K (2001) Determination of flavonols in green and black tea leaves and green tea infusions by high performance liquid chromatography. Food Res Int 34:223–227

Farhoosh R, Golmovahhed GA, Khodaparast MHH (2007) Antioxidant activity of various extracts of old tea leaves and black tea wastes (Camellia sinensis L.). Food Chem 100(1):231–236

Zuo Y, Chen H, Deng Y (2002) Simultaneous determination of catechins, caffeine, and gallic acids in green, oolong, black, and pu-erh teas using HPLC with a photodiode array detector. Talanta 57(2):307–316

Rostami H, Gharibzahedi SMT (2017) Cellulase-assisted extraction of polysaccharides from Malva sylvestris: process optimization and potential functionalities. Int J Biol Macromol 101:196–206

Jun X, Deji S, Ye L, Rui Z (2011) Comparison of in vitro antioxidant activities and bioactive components of green tea extracts by different extraction methods. Int J Pharm 408:97–101

Spigno G, De Faveri DM (2009) Microwave-assisted extraction of tea phenols: a phenomenological study. J Food Eng 93(2):210–217

Bermejo DV, Mendiola JA, Ibáñez E, Reglero G, Fornari T (2015) Pressurized liquid extraction of caffeine and catechins from green tea leaves using ethyl lactate, water and ethyl lactate + water mixtures. Food Bioprod Process 96:106–112

Bermejo DV, Ibáñez E, Reglero G, Turner C, Fornari T, Rodriguez-Meizoso I (2015) High catechins/low caffeine powder from green tea leaves by pressurized liquid extraction and supercritical antisolvent precipitation. Sep Purif Technol 148:49–56

Nkhili E, Tomao V, El Hajji H, El Boustani ES, Chemat F, Dangles O (2009) Microwave-assisted water extraction of green tea polyphenols. Phytochem Anal 20(5):408–415

Raghunath S, Mallikarjunan K (2020) Optimization of ultrasound-assisted extraction of cold-brewed black tea using response surface methodology. J Food Process Eng 43(11):e13540

Xi J, He L, Yan L (2015) Kinetic modeling of pressure-assisted solvent extraction of polyphenols from green tea in comparison with the conventional extraction. Food Chem 166:287–291

Zderic A, Zondervan E (2016) Polyphenol extraction from fresh tea leaves by pulsed electric field: a study of mechanisms. Chem Eng Res Des 109:586–592

Zhao W, Yang R, Wang M (2009) Cold storage temperature following pulsed electric fields treatment to inactivate sublethally injured microorganisms and extend the shelf life of green tea infusions. Int J Food Microbiol 129(2):204–208

Zhao W, Yang R, Wang M, Lu R (2009) Effects of pulsed electric fields on bioactive components, color and flavor of green tea infusions. Int J Food Sci Technol 44(2):312–321

Chang CJ, Chiu KL, Chen YL, Yang PW (2001) Effect of ethanol content on carbon dioxide extraction of polyphenols from tea. J Food Compos Anal 14:75–82

Pan X, Niu G, Liu H (2003) Microwave-assisted extraction of tea polyphenols and tea caffeine from green tea leaves. Chem Eng Process 42:129–133

Rehder AP, Silva PB, Xavier AMF, Barrozo MAS (2021) Optimization of microwave-assisted extraction of bioactive compounds from a tea blend. Journal of Food Measurement and Characterization 15(2):1588–1598

Xia T, Shi S, Wan X (2006) Impact of ultrasonic-assisted extraction on the chemical and sensory quality of tea infusion. J Food Eng 74(4):557–560

Sáenz-Galindo A, Castañeda-Facio AO, Cedillo-Portillo JJ, Vera-García PF, De León-Martínez PA, Rodríguez-Herrera R (2021) Ultrasound-assisted process: Applications in reactions, extraction, and surface modifications. In: Handbook of Greener Synthesis of Nanomaterials and Compounds pp 247–272

Piñeiro Z, Palma M, Barroso CG (2004) Determination of catechins by means of extraction with pressurized liquids. J Chromatogr A 1026:19–23

Culetu A, Héritier J, Andlauer W (2015) Valorisation of theanine from decaffeinated tea dust in bakery functional food. Int J Food Sci Technol 50(2):413–420

Yagmur E, Ozmak M, Aktas Z (2008) A novel method for production of activated carbon from waste tea by chemical activation with microwave energy. Fuel 87(15–16):3278–3285

Leonelli C, Mason TJ (2010) Microwave and ultrasonic processing: now a realistic option for industry. Chem Eng Process 49(9):885–900

Wang T, Qu G, Pei S, Liang D, Hu S (2016) Research on dye wastewater decoloration by pulse discharge plasma combined with charcoal derived from spent tea leaves. Environ Sci Pollut Res 23(13):13448–13457

Xu YQ, Zou C, Gao Y, Chen JX, Wang F, Chen GS, Yin JF (2017) Effect of the type of brewing water on the chemical composition, sensory quality and antioxidant capacity of Chinese teas. Food Chem 236:142–151

Gardner E, Ruxton C, Leeds A (2007) Black tea – helpful or harmful? A review of the evidence. Eur J Clin Nutr 61:3–18

Astill C, Birch MR, Dacombe C, Humphrey PG, Martin PT (2001) Factors affecting the caffeine and polyphenol contents of black and green tea infusions. J Agric Food Chem 49(11):5340–5347

Bortolini DG, Haminiuk CWI, Pedro AC, Fernandes IDAA, Maciel GM (2021) Processing, chemical signature and food industry applications of Camellia sinensis teas: an overview. Food Chemistry: X 12:100160

Tanaka T, Inoue K, Betsumiya Y, Mine C, Kouno I (2001) Two types of oxidative dimerization of the black tea polyphenol theaflavin. J Agric Food Chem 49(12):5785–5789

Hung YC, Hsiao YH, Hsieh JF (2021) Catechin content and free radical scavenging activity of Camellia sinensis twig extract. Int Food Res J 8(2):248–254

Miyoshi N, Tanabe H, Suzuki T, Saeki K, Hara Y (2020) Applications of a standardized green tea catechin preparation for viral warts and human papilloma virus-related and unrelated cancers. Molecules 25(11):22–88

Friedman M, Kim SY, Lee SJ, Han GP, Han JS, Lee KR, Kozukue N (2005) Distribution of catechins, theaflavins, caffeine, and theobromine in 77 teas consumed in the United States. J Food Sci 70(9):C550–C559

Zhang C, Suen CL-C, Yang C, Quek SY (2018) Antioxidant capacity and major polyphenol composition of teas as affected by geographical location, plantation elevation, and leaf grade. Food Chem 244:109–119

Choi SJ, Park SY, Park JS, Park SK, Jung MY (2016) Contents and compositions of policosanols in green tea (Camellia sinensis) leaves. Food Chem 204:94–101

Katiyar SK (2011) Green tea prevents non-melanoma skin cancer by enhancing DNA repair. Arch Biochem Biophys 508:152–158

Mantena SK, Meeran SM, Elmets CA, Katiyar SK (2005) Nutrition and cancer: Orally administered green tea polyphenols prevent ultraviolet radiation- induced skin cancer in mice through activation of cytotoxic T cells and inhibition of angiogenesis in tumors. J Nutr 135:2871–2877

Rees JR, Stukel TA, Perry AE, Zens MS, Spencer SK, Karagas MR (2007) Tea consumption and basal cell and squamous cell skin cancer: results of a case-control study. J Am Acad Dermatol 56(5):781–785

Saha P, Das S (2002) Elimination of deleterious effects of free radicals in murine skin carcinogenesis by black tea infusion, theaflavins and epigallocatechin gallate. Asian Pac J Cancer Prev 3(3):225–230

Deb G, Thakur VS, Limaye AM, Gupta S (2015) Epigenetic induction of tissue inhibitor of matrix metalloproteinase-3 by green tea polyphenols in breast cancer cells. Mol Carcinog 54(6):485–499

Shivaji K, Balasubramanian MG, Devadoss A, Asokan V, De Castro CS, Davies ML, Ponmurugan P, Pitchaimuthu S (2019) Utilization of waste tea leaves as bio-surfactant in CdSquantum dots synthesis and their cytotoxicity effect in breastcancer cells. Appl Surf Sci 487:159–170

Sun CL, Yuan JM, Koh WP, Yu MC (2006) Green tea, black tea and breast cancer risk: a meta-analysis of epidemiological studies. Carcinogenesis 27(7):1310–1315

Thangapazham RL, Singh AK, Sharma A, Warren J, Gaddipati JP, Maheshwari RK (2006) Green tea polyphenols and its constituent epigallocatechin gallate inhibits proliferation of human breast cancer cells in vitro and in vivo. Cancer Lett 245(1–2):232–241

Gao Y, Rankin GO, Tu Y, Chen YC (2016) Inhibitory effects of the four main theaflavin derivatives found in black tea on ovarian cancer cells. Anticancer Res 36(2):643–651

Gosvig CF, Kjaer SK, Blaakær J, Høgdall E, Høgdall C, Jensen A (2015) Coffee, tea, and caffeine consumption and risk of epithelial ovarian cancer and borderline ovarian tumors: results from a Danish case-control study. Acta Oncol 54(8):1144–1151

Lee PM, Ng CF, Liu ZM, Ho WM, Lee MK, Wang F, Kan HD, He YH, Ng SS, Wong SY, Tse LA (2017) Reduced prostate cancer risk with green tea and epigallocatechin 3-gallate intake among Hong Kong Chinese men. Prostate Cancer Prostatic Dis 20(3):318–322

Wang P, Henning SM, Heber D, Vadgama JV (2015) Sensitization to docetaxel in prostate cancer cells by green tea and quercetin. J Nutr Biochem 26:408–415

Fu H, He J, Mei F, Zhang Q, Hara Y, Ryota S, Lubet RA, Chen R, Chen DR, You M (2009) Lung cancer inhibitory effect of epigallocatechin-3-gallate is dependent on its presence in a complex mixture (polyphenon E). Cancer Prevent Res 2(6):531–537

Hudlikar RR, Venkadakrishnan VB, Kumar R, Thorat RA, Kannan S, Ingle AD, Desai S, Maru GB, Mahimkar MB (2017) Polymeric black tea polyphenols (PBPs) inhibit benzo(a)pyrene and 4-(methylnitrosamino)-1-(3-pyridyl)-1- butanone-induced lung carcinogenesis potentially through down-regulation of p38 and Akt phosphorylation in A/J mice. Mol Carcinogen 56(2):625–640

Chen F, He BC, Yan LJ, Liu FP, Huang JF, Hu ZJ, Lin Z, Zheng XY, Lin LS, Zhang ZF, Cai L (2017) Tea consumption and its interactions with tobacco smoking and alcohol drinking on oral cancer in southeast China. Eur J Clin Nutr 71(10):481–485

Wang W, Yang Y, Zhang W, Wu W (2014) Association of tea consumption and the risk of oral cancer: a meta-analysis. Oral Oncol 50:276–281

Henning SM, Wang P, Abgaryan N, Vicinanza R, de Oliveira DM, Zhang Y, Heber D (2013) Phenolic acid concentrations in plasma and urine from men consuming green or black tea and potential chemopreventive properties for colon cancer. Mol Nutr Food Res 57(3):483–493

Su LJ, Arab L (2002) Tea consumption and the reduced risk of colon cancer–results from a national prospective cohort study. Public Health Nutr 5(3):419–425. https://doi.org/10.1079/phn2001314

Yang C, Du W, Yang D (2016) Inhibition of green tea polyphenol EGCG((−)-epigallocatechin-3-gallate) on the proliferation of gastric cancer cells by suppressing canonical wnt/β-catenin signalling pathway. Int J Food Sci Nutr 67(7):818–827

Bimonte S, Cascella M, Leongito M, Palaia R, Caliendo D, Izzo F, Cuomo A (2017) An overview of pre-clinical studies on the effects of (-)-epigallocatechin-3-gallate, a catechin found in green tea, in treatment of pancreatic cancer. Recenti Prog Med 108(6):282–287

Lai NHT, Bautista JK, Rodriguez A, Bolivar S, Joseph EE (2017) EGCG, An active ingredient in green tea, modulates cell proliferation in human pancreatic cancer cells and rat osteosarcoma cells in vitro. FASEB J (31), lb29-lb29

Lai NH, Bautista JK, Rodriguez A, Bolivar S, Joseph EE (2017) EGCG, An active ingredient in green tea, modulates cell proliferation in human pancreatic cancer cells and rat osteosarcoma cells in vitro. FASEB J 31(S1):lb29-lb29

Sur S, Panda CK (2017) Molecular aspects of cancer chemopreventive and therapeutic efficacies of tea and tea polyphenols. Nutrition 43–44:8–15

Cheng KW, Wong CC, Chao J, Lo C, Chen F, Chu IK, Che CM, Ho CT, Wang M (2009) Inhibition of mutagenic PhIP formation by epigallocatechin gallate via scavenging of phenylacetaldehyde. Mol Nutr Food Res 53(6):716–725

Danesi F, Philpott M, Huebner C, Bordoni A, Ferguson LR (2010) Food-derived bioactives as potential regulators of the IL-12/IL-23 pathway implicated in inflammatory bowel diseases. Mutation Research - Fundamental and Molecular Mechanisms of Mutagenesis 690:139–144

Moon HS, Akbar M, Yun CH, Cho CS (2009) Mechanisms of (-)epigallocatechin-3-gallate for antiobesity. In: Weight Control and Slimming Ingredients in Food Technology pp 177–199

Osterburg A, Gardner J, Hyon SH, Neely A, Babcock G (2009) Highly antibiotic-resistant Acinetobacter baumannii clinical isolates are killed by the green tea polyphenol (-)-epigallocatechin-3-gallate (EGCG). Clin Microbiol Infect 15(4):341–346

Shang A, Li J, Zhou DD, Gan RY, Li HB (2021) Molecular mechanisms underlying health benefits of tea compounds. Free Radical Biol Med 172:181–200

Singh R, Akhtar N, Haqqi TM (2010) Green tea polyphenol epigallocatech-3-gallate: Inflammation and arthritis. Life Sci 86(25–26):907–918

Smith A, Giunta B, Bickford PC, Fountain M, Tan J, Shytle RD (2010) Nanolipidic particles improve the bioavailability and alpha-secretase inducing ability of epigallocatechin-3-gallate (EGCG) for the treatment of Alzheimer’s disease. Int J Pharm 389:207–212

Xiao X, Yang Z, Shi L, Liu J, Chen W (2008) Antiviral effect of epigallocatechin gallate (EGCG) on influenza A virus. Zhongguo Zhong Yao Za China Journal of Chinese Materia Medica 33(22):2678–2682

Zhang ZF, Li Q, Liang J, Dai XQ, Ding Y, Wang JB, Li Y (2010) Epigallocatechin-3-O-gallate (EGCG) protects the insulin sensitivity in rat L6 muscle cells exposed to dexamethasone. Phytomedicine 17:14–18

Câmara JS, Albuquerque BR, Aguiar J, Corrêa RC, Gonçalves JL, Granato D, Pereira JA, Barros L, Ferreira IC (2021) Food bioactive compounds and emerging techniques for their extraction: polyphenols as a case study. Foods 10:7

Zhu Y, Xie DY (2020) Docking characterization and in vitro inhibitory activity of flavan-3-ols and dimeric proanthocyanidins against the main protease activity of SARS-Cov-2. Front Plant Sci 11:1–14

Senol A, Aydin A (2006) Solid-liquid extraction of caffeine from tea waste using battery type extractor: Process optimization. J Food Eng 75(4):565–573

Higashiyama A, Htay HH, Ozeki M, Juneja LR, Kapoor MP (2011) Effects of l-theanine on attention and reaction time response. J Funct Foods 3(3):171–178

Owen GN, Parnell H, De Bruin EA, Rycroft JA (2008) The combined effects of L-theanine and caffeine on cognitive performance and mood. Nutr Neurosci 11(4):193–198

Vuong QV, Bowyer MC, Roach PD (2011) L-Theanine: properties, synthesis and isolation from tea. J Sci Food Agric 91(11):1931–1939

Wang L, Qin P, Hu Y (2010) Study on the microwave-assisted extraction of polyphenols from tea. Front Chem Eng China 4(3):307–313

Wang Y, Yang X, Li K, Li C, Li L, Li J, Huang H, He Y, Ye C, Song X (2010) Simultaneous determination of theanine, gallic acid, purine alkaloids, catechins, and theaflavins in black tea using HPLC. Int J Food Sci Technol 45(6):1263–1269

Yan J, Di X, Liu C, Zhang H, Huang X, Zhang J, Zhao Y, Zhang L, Chang Y, Liang Y, Tao R (2010) The cessation and detoxification effect of tea filters on cigarette smoke. Sci China Life Sci 53(5):533–541

Li BB, Smith B, Hossain MM (2006) Extraction of phenolics from citrus peels: I. Solvent extraction method. Sep Purif Technol 48(2):182–188

Guo W, Beta T (2013) Phenolic acid composition and antioxidant potential of insoluble and soluble dietary fiber extracts derived from select whole-grain cereals. Food Res Int 51(2):518–525

Teixeira DM, Patão RF, Coelho AV, da Costa CT (2006) Comparison between sample disruption methods and solid–liquid extraction (SLE) to extract phenolic compounds from Ficus carica leaves. J Chromatogr A 1103(1):22–28

Vatai T, Škerget M, Knez Ž (2009) Extraction of phenolic compounds from elder berry and different grape marc varieties using organic solvents and/or supercritical carbon dioxide. J Food Eng 90(2):246–254

Bonoli M, Marconi E, Caboni MF (2004) Free and bound phenolic compounds in barley (Hordeum vulgare L.) flours: evaluation of the extraction capability of different solvent mixtures and pressurized liquid methods by micellar electrokinetic chromatography and spectrophotometry. J Chromatogr A 1057(1–2):1–12

Chávez-González ML, Sepúlveda L, Verma DK, Luna-García HA, Rodríguez-Durán LV, Ilina A, Aguilar CN (2020) Conventional and emerging extraction processes of flavonoids. Processes 8(4):434

Kalia K, Sharma K, Singh HP, Singh B (2008) Effects of extraction methods on phenolic contents and antioxidant activity in aerial parts of Potentilla atrosanguinea lodd and quantification of its phenolic constituents by RP-HPLC. J Agric Food Chem 56(21):10129–10134

Kumar PS, Kumar NA, Sivakumar R, Kaushik C (2009) Experimentation on solvent extraction of polyphenols from natural waste. J Mater Sci 44(21):5894–5899

Stalikas CD (2007) Extraction, separation, and detection methods for phenolic acids and flavonoids. J Sep Sci 30(18):3268–3295